CAUTION

To reship, re-affix the screws

to their original positions.

Ensure that the two screws on

the bottom surface (for break-

age prevention during trans-

port) are removed before use.

5-1.

Assemble the soldering iron

stand following the instructions

on its box.

SVS

-58

0AS

HEATER

1

0

HEATER

1

0

250

350

450

400

300

HEAT

TEMP[C]

200

480

350

300

250

450

TEMP[C]

HEAT

SVS-580AS

SO

LD

ER

ING

IR

ON

DE

SO

LD

ER

ING

GU

N

SER

VIC

E S

TA

TIO

N

MAIN

POWER

1

0

DE

SO

LD

ER

ING

IRO

N

IRO

N

VA

CU

UM

SO

LD

ER

ING

SERVICE STATION

SVS-500AS

/

SVS-580AS

Some smoke will be produced from the

desoldering gun during initial operation,

but it will soon stop. No smoke

produced after the initial operation.

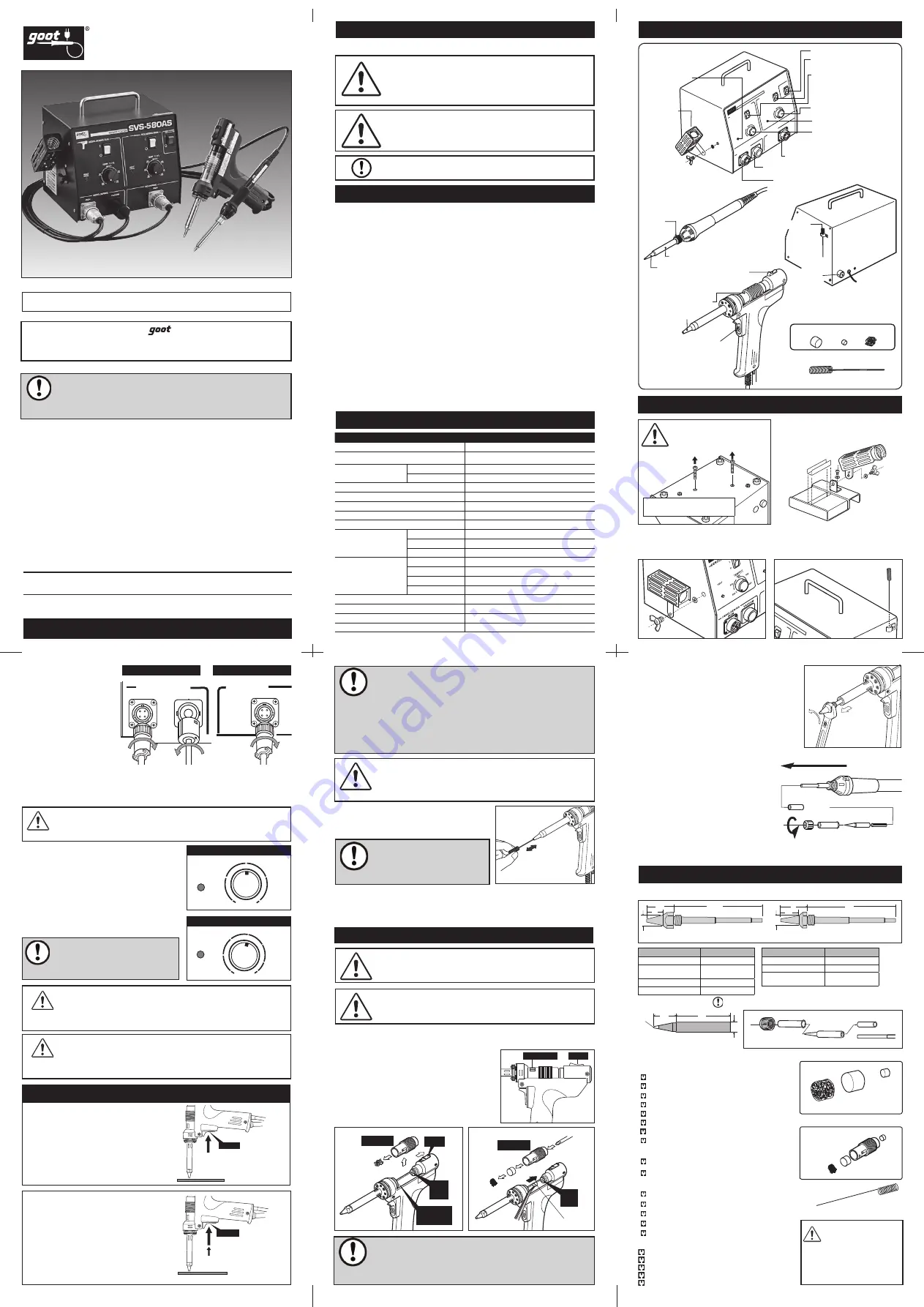

4. PACKAGE CONTENTS / NAMES OF PARTS

5. SETTING

6.

OPERATION

8. REPLACEMENT PARTS

WARNING

WARNING

WARNING

WARNING

5-3.

Place the cleaning pin into its holder,

provided at the rear right side of the

control box.

5-4.

Connect the desolder-

ing gun & soldering

iron to the control box.

(ex.)

SVS-500AS

5-8.

Turn the main power switch ON (to I

side). Turn the power switch for desol-

dering gun and/or soldering iron ON (to

I side). The [

HEAT

] lamp will light up and

the heater will start heating up. When

the [

HEAT

] lamp flashes the machine is

ready to use. (approx. 2-3

mins)

5-6.

Check that the main power switch on the control box is OFF (

side) and

then plug in the control box.

5-7.

Set the desired temperature using the

temperature setting knob.

Ensure that the unit is properly grounded to avoid

electrical shock. The desoldering gun & the solder-

ing iron are conductive.

Never touch the nozzle, tip, or other metal / plastic part.

These areas get very hot. Possibly resulting in serious

personal injury or damage. Be sure that the nozzle / tip has

sufficiently cooled down when storing.

Use this desolder-

ing gun exclusively

to prevent the injury

or damage.

To prevent fire or personal injury, turn off and unplug the

desoldering station if there is a burning smell, overheating,

or if the plastic parts deform. Do not use it again and con-

tact your nearest distributor.

■

TIP

■ステーション部

■こて台 ■取扱説明書

HE

ATER

1

0

HEA

TER

1

0

250

350

450

400

300

HEA

T

TEMP[C]

20

0

480

350

300

250

450

TEMP[C]

HE

AT

SVS

-58

0AS

SO

LD

ER

IN

G

IR

ON

DE

SO

LD

ER

IN

G

GU

N

SE

RV

IC

E S

TA

TIO

N

MAIN

POWER

1

0

DE

SO

LD

ER

IN

G

IR

ON

VA

CU

UM

IR

ON

SO

LD

ER

IN

G

Power Supply Connector for

Desoldering Gun

Vacuum Hose Connector

Power Supply Connector for

Soldering Iron

Power Switch for

Soldering Iron

Power Switch for

Desoldering Gun

Main Power Switch

Temperature Setting Knob for

Desoldering Gun

Heat Lamp for Soldering Iron

Temperature Setting Knob for

Soldering Iron

250V 4A

100V AC

Fuse Holder

Slider

Cartridge

Nozzle

Trigger

Collar

Heater Barrel

Tip

Heat Lamp for

Desoldering Gun

Desoldering

Gun Holster

Cleaning Pin Holder

Felt A

Felt B Steel Wool

(

TP-100CP1.3

in

SVS-580AS

)

Felt A

Felt B Steel Wool

(

TP-100CP1.3

in

SVS-580AS

)

■

Cleaning Pin TP-100CP0.7

■

Soldering Iron Stand ST-76

■

Operation Manual

■

Filter Set TP-100F

NOTE

MODEL

SVS-500AS

SVS-580AS

Voltage

110V, 120-130V, 220-240V AC 50/60Hz

Power Consumption

110V, 120-130V(200W), 220-240V(270-300W)

Temp. Setting Range

Desoldering Gun

250−450˚C (482-842˚F)

Soldering Iron

200−480˚C (392-896˚F)

Heater

Ceramic heater with internal sensor

Temperature Control System

Sensor feedback (ON-OFF control)

Insulation Resistance

Over 100M

Ω

Vacuum Pump System

Diaphragm system

Ultimate Pressure

- 0.08MPa (-600mmHg)

Dimensions

Control Box

205

(

W

)

×160

(

L

)

×170

(

H

)

mm

Desoldering Gun

220×155mm

Soldering Iron

190mm

Weight

Control Box

Approx.3.6kg (w/o cord, hose)

Desoldering Gun

250g (w/o cord)

Soldering Iron

70g

Total

Approx. 4.0kg

Leak Voltage

Less than 2mV

Ground/Earth Resistance

Less than 2

Ω

Connecting cord length

1.2m

Power cord length

3-prong cord 1.5m

SVS-580AS

5-2.

Attach the desoldering gun hol-

ster.

Fuse: 250V 4A

■

Desoldering Gun

■

Soldering Iron

■

Control Box

SOLDERING

IRON

DESOLDERING

IRON

VACUUM

OPEN

350

450

250

400

300

(572)

(752)

(842)

(482)

(662)

HEAT

350

480

250

400

300

(572)

(752)

(896)

450

(842)

(482)

200

(392)

(662)

HEAT

REPLACEMENT OF TIP

1.

Remove the collar by turning it in a

counter-clockwise direction.

2.

Pull out the heater barrel, then pull

out the tip from the heater.

3.

Be sure that the leaf spring (a rolled

metal spring normally stuck inside

the tip) is not stuck to the heater.

4.

Reassemble with new tip, reversing these steps.

5-5.

Put the desoldering gun into its holster, and the soldering iron into its stand.

Desoldering Gun

Desoldering Gun

Soldering Iron

Soldering Iron

Tip

Spacer

Heater

Heater Barrel

Collar

Standard

37

R0.3

φ

7

15

15

36

37.5

φ

8

1.2

φ

3

37

15

φ

7

37

16

φ

5

φ

7

37

15

φ

7

R0.5

φ

5

37

16

φ

7

1

φ

7

φ

5

37

15

37

15

2

φ

5

φ

7

37

15

φ

2.1

φ

7

37

15

φ

7

1

0.5

φ

7

φ

4

37

15

PX-2RT-SB

PX-2RT-6E

PX-2RT-5D

PX-2RT-2C

φ

7

φ

2.4

37

15

0.5

PX-2RT-2.4D

φ

7

φ

1.6

37

15

0.5

PX-2RT-1.6D

PX-2RT-3C

PX-2RT-B

PX-2RT-5K

φ

7

φ

3.2

37

15

0.5

PX-2RT-3.2D

PX-2RT-8S

PX-2RT-5C

PX-2RT-BC

PX-2RT-4D

φ

4

37

15

φ

7

PX-2RT-4C

全周はんだメッキ仕様

全周はんだメッキ仕様(C型)

標準タイプ(C型)

φ

3

37

15

φ

7

φ

5

37

16

φ

7

37

15

φ

2.1

φ

7

PX-2RT-2CR

PX-2RT-3CR

PX-2RT-5CR

φ

4

37

15

φ

7

PX-2RT-4CR

Please refer to our website about other replacement tips.

WARNING

CAUTION

NOTE

Failure to obey a safety warning could result in

serious injury or death to yourself or to others, or

in physical damage.

Failure to obey a safety warning could result in

injury to yourself or to others, or in physical damage.

A note or word of advice.

In this manual, the following safety marks are used.

This is a common operation manual for

SVS-500AS

&

SVS-580AS

. Each model number is mentioned in the text.

Be sure to read properly for your model.

1. SAFETY MARK DEFINITIONS

2. FOR SAFE OPERATION

3. SPECIFICATIONS

1. Do not use in dangerous environments. Never use it in damp, humid

or wet locations (including outside), or near flammable substances.

2. Keep children and bystanders away from the unit.

3. Turn off the power when not in use.

4. Your desoldering station is an electrical tool used to remove solder in

order to free components from printed circuit boards. Do not use this

for any other purpose.

5. Wear proper apparel and safety glasses.

6. Connect to a correct AC power supply. Do not use with any power

voltage other than the indicated voltage.

7. If the power cord, desoldering-gun cord, or soldering-iron cord is

damaged, stop using immediately and turn off the power. Return to

the distributor for replacement.

8. Be sure to use the ST-76 soldering iron stand included with this

Soldering station. Other soldering iron stands may melt the parts of this

unit.

9. Make sure that the machine must be grounded at all times to prevent

electrical shocks and static electricity.

1. SAFETY MARK DEFINITIONS

2. FOR SAFE OPERATION

3. SPECIFICATIONS

4. PACKAGE CONTENTS / NAME OF PARTS

5. SETTING

6. OPERATION

7. MAINTENANCE

8. REPLACEMENT PARTS

TAIYO ELECTRIC IND.CO.,LTD.

KEEP THIS MANUAL FOR FUTURE REFERENCE

Thank you for buying the

Service Station. Read

this Owner’s Operation Manual before using your

service station.

NOTE

www.goot.co.jp

E-mail:

OPERATION MANUAL

7. MAINTENANCE

SVS-500AS

Place the nozzle over the leads of the

component to be removed. Wait until

the solder melts, then pull the trigger for

desoldering.

SVS-580AS

Place the nozzle over the leads of the

component to be removed. Wait until the

solder melts, then pull the trigger slightly.

The pump starts operating, and the vacuum

is created in the vacuum chamber. Next, pull

the trigger more. The open-valve will open,

and the solder is pumped.

After desoldering operation, remove any solder

scraps on the nozzle by the wetted heat-

resistant sponge on the soldering iron stand.

When operation is completed, push in and pull out the cleaning pin 3 or 4

times (to reduce nozzle clogs). Lastly, do not fail to put the pretinning on the

nozzle tip (to prevent oxidation of the nozzle tip).

REPLACEMENT OF NOZZLE

When the clogged collected solder in the nozzle

cannot be removed by the cleaning pin or

cleaning drill, the nozzle needs to be replaced.

1.

Turn the nozzle counterclockwise using a

wrench (11mm) and remove it.

2.

Replace with a new nozzle. Be careful not to

overtighten it.

1.

Pull back the slider and take out the cartridge.

2.

Remove the solder scraps from the cartridge.

3.

Connect the arrow side of the cartridge to the

front ring gasket. Return the slider to the front.

Make sure that the rear plug goes into the

cartridge.

Arrow Mark

Slider

Tweezers

Steel

Wool

Felt A

Felt B

Screwdriver

Cartridge

Rear

Plug

Collected

Solder Scrap

Front Ring

Gasket

Rear

Plug

Slider

Cartridge

Overall View

(Standard Type)

Overall View

(Slim Type)

20

20

77.5

77.5

12

φ

8.0

φ

6.4

14

Filter Set TP-100F

Cartridge Set TP-100K

Cleaning Pin

■

NOZZLE

Part NO.

Gauge

TP-100N-08

φ

0.8mm

TP-100N-10

(

SVS-500AS

Standard

)

φ

1.0mm

TP-100N-15

φ

1.5mm

TP-100N-25

φ

2.5mm

Part NO.

Gauge

TP-100N-S8

φ

0.8mm

TP-100N-S1

φ

1.0mm

TP-100N-S5

(

SVS-580AS

Standard

)

φ

1.5mm

Felt A

Felt B

Steel Wool

Steel

Wool

Felt A

Felt B

Cartridge

(1pcs)

(3pcs)

Trigger

Trigger

Pull trigger when solder melts.

1. Place against the leads,

and pull trigger slightly.

2. When solder has melted,

pull trigger fully.

Trigger

Trigger

Pull trigger when solder melts.

1. Place against the leads,

and pull trigger slightly.

2. When solder has melted,

pull trigger fully.

Turn off the main power switch (to

side),

unplug the power cord before maintenance.

And be sure that the nozzle / tip is cooled down.

Use only genuine goot replacement parts for

maintenance. The use of any other parts may

be hazardous and cause damage to the unit.

Do not pull the trigger for more than 2 seconds.

Wait at least 10 seconds between trigger pulls.

Failure to do so could result in the heater or

motor overheating.

SVS-500AS

After releasing the trigger, the pump will operate

for approx. 0.5 seconds more, to pump the collected solder in the

nozzle.

SVS-580AS

When the vacuum chamber is completely filled,

the pump cannot take effect even if the trigger is pulled. In that

case, pull the trigger in completely. The open-valve will open, and

restore negative pressure in the chamber. Then the pump will

operate again.

Clean the nozzle with the cleaning

pin frequently during desoldering

work. A cleaning drill is an optional

part for some nozzle sizes.

NOTE

NOTE

WARNING

CAUTION

CAUTION

CLEANING AND REPLACEMENT OF CARTRIDGE, FILTER

■

REPLACEMENT PARTS

Cleaning Pin

Cleaning Pin Vice

(Option)

Soldering Iron

Exclusive for

SVS-500AS

......

TP-20GAS

Heater

..................................

TP-100H

Exclusive for

SVS-580AS

......

TP-28GAS

Heater barrel

.....................

TP-100HP

Desoldering Gun

φ

0.7mm

(for

φ

0.8 & 1.0mm nozzle)

.......

TP-100CP 0.7

Pin vice body (The drill bit is not included.) ..............

TP-100PV

φ

1.3mm (for

φ

1.5 & 2.5mm nozzle) ..........

TP-100CP 1.3

Drill Bit

φ

0.7mm......................................

TP-100DB-07

Drill Bit

φ

0.9mm......................................

TP-100DB-09

Drill Bit

φ

1.4mm......................................

TP-100DB-14

Drill Bit

φ

2.4mm......................................

TP-100DB-24

Heater

....................................................................

SVS-500H-1

Heater barrel

...........................................................

TQ-77HP

Spacer

......................................................................

TQ-77SS

Collar

........................................................................

TQ-77NUT

Soldering iron unit

(common for

SVS-500

/

580

) ....

SVS-50GAS

Filter Set (3pcs)

.............

TP-100F

Felt B (10pcs)

................

TP-100RFT

Cartridge Set

................

TP-100K

Steel Wool Only

............

TP-100UL

Do not use this desoldering gun without both felt A and felt B.

The pump could be damaged.

SVS-580AS

: The powerful suction

makes many more filter clogs than

SVS-500AS

. Requires frequent

replacing of the filter to maintain desoldering power.

NOTE

Tip Spring

Spacer

Heater

Heater

Barrel

Collar

Printed in Japan, MAY 2013 A4610AH01