11

5. When directly communicating with the outdoors, the single open-

ing shall have a minimum free area of 1 square inch per 3,000

BTU per hour of total input rating of all equipment in the enclo-

sure.

5.3.4 Specially Engineered Installations:

The requirements of 5.3.3 shall not necessarily govern when special engi-

neering, approved by the authority having jurisdiction, provides an ad-

equate supply of air for combustion, ventilation, and dilution of flue

gases.

5.3.5 Louvers and Grilles:

In calculating free area in 5.3.3, consideration shall be given to the block-

ing effect of louvers, grilles or screens protecting openings. Screens

used shall not be smaller than 1/4 inch mesh. If the area through a

design of louver or grille is known, it should be used in calculating the

size of opening required to provide the free area specified. If the design

and free area is not known, it may be assumed that wood louvers will

have 20-25 percent free area and metal louvers and grilles will have 60-

75 percent free area. Louvers and grilles shall be fixed in the open

position or interlocked with the equipment so that they are opened au-

tomatically during equipment operation.

5.3.6 Special Conditions Created by Mechanical Exhausting or Fire-

places:

Operation of exhaust fans, ventilation systems, clothes dryers, or fireplaces

may create conditions requiring special attention to avoid unsatisfac-

tory operation of installed gas utilization equipment. Air from Inside

Building. See 5.3.3-a.

VI. INST

VI. INST

VI. INST

VI. INST

VI. INSTALL

ALL

ALL

ALL

ALLA

A

A

A

ATI

TI

TI

TI

TIO

O

O

O

ON POSITI

N POSITI

N POSITI

N POSITI

N POSITIO

O

O

O

ONS

NS

NS

NS

NS

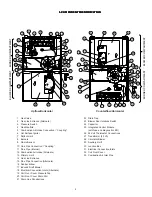

This furnace may be installed in an upright position or horizontal on

either the left or right side panel. Do not install this furnace on its

back. For

upright upflow

furnaces, return air ductwork may be at-

tached to the side panel(s) and/or basepan. For

horizontal upflow

furnaces, return air ductwork must be attached to the basepan. For

both

upright or horizontal counterflow

furnaces, return ductwork must

be attached to the basepan (top end of the blower compartment).

NOTE:

Ductwork must never be attached to the back of the fur-

nace. Contact your distributor for proper airflow requirements and

number of required ductwork connections. Refer to “Recommended

Installation Positions” figure for appropriate installation positions,

ductwork connections, and resulting airflow arrangements.

VII. HO

VII. HO

VII. HO

VII. HO

VII. HORIZO

RIZO

RIZO

RIZO

RIZONT

NT

NT

NT

NTAL APPLI

AL APPLI

AL APPLI

AL APPLI

AL APPLIC

C

C

C

CA

A

A

A

ATI

TI

TI

TI

TIO

O

O

O

ONS & CO

NS & CO

NS & CO

NS & CO

NS & CONSID

NSID

NSID

NSID

NSIDERA

ERA

ERA

ERA

ERATI

TI

TI

TI

TIO

O

O

O

ONS

NS

NS

NS

NS

G

ENERAL

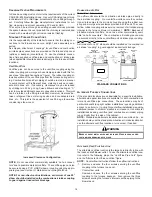

Horizontal applications, in particular, may dictate many of the

installation’s specifics such as airflow direction, ductwork connec-

tions, flue and combustion air pipe connections, etc. The basic ap-

plication of this furnace as a horizontal furnace differs only slightly

from an upright installation. When installing a furnace horizontally,

additional consideration must be given to the following:

ALTERNATE VENT/FLUE

AND COMBUSTION AIR

INTAKE LOCATIONS

FURNACE MUST BE LEVEL

FROM END TO END

FURNACE MUST BE LEVEL

OR SLIGHTLY TILTED FORWARD

WITH THE DOORS 0" - 3/4"

BELOW THE BACK PANEL

DRAIN LINE WITH 1/4" PER FOOT

DOWNWARD SLOPE

36" MINIMUM SERVICE

CLEARANCE REQUIRED

FURNACE MUST BE SUPPORTED

AT BOTH ENDS AND MIDDLE

DRAIN PAN

GAS LINE WITH

DRIP LEG (3" MINIMUM)

4 3/4" MINIMUM

DRAIN TRAP

CLEARANCE

Horizontal Furnace

D

RAIN

T

RAP

AND

L

INES

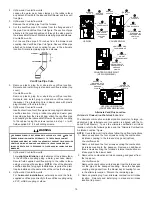

In horizontal applications the condensate drain trap is secured to

the furnace side panel, suspending it below the furnace. A mini-

mum clearance of 4 3/4 inches below the furnace must be provided

for the drain trap. Additionally, the appropriate downward piping

slope must be maintained from the drain trap to the drain location.

Refer to

Section X, Condensate Drain Trap and Lines

for further

details. If the drain trap and drain line will be exposed to tempera-

tures near or below freezing, adequate measures must be taken to

prevent condensate from freezing.

L

EVELING

Leveling ensures proper condensate drainage from the heat ex-

changer and induced draft blower. For proper flue pipe drainage,

the furnace must be level lengthwise from end to end. The furnace

should also be level from back to front or have a slight tilt with the

access doors downhill (approximately 3/4 inches) from the back

panel. The slight tilt allows the heat exchanger condensate, gener-

ated in the recuperator coil, to flow forward to the recuperator coil

front cover.

A

LTERNATE

V

ENT

/F

LUE

AND

C

OMBUSTION

A

IR

C

ONNECTIONS

In horizontal installations provisions for alternate flue and combus-

tion air piping are available for upflow furnaces with left discharge

and counterflow furnaces with right air discharge. This configura-

tion allows the flue and combustion air piping to be run vertically

through the furnace. Refer to the “Recommended Installation Posi-

tions” figure for further detail. The standard piping connections may

also be used in these positions. Refer to

Section IX, Vent/Flue Pipe

and Combustion Air Pipe for details concerning the conversion to

the alternate vent/flue and combustion air connections.