15

4. Use a knockout tool to create a 3" diameter hole

5. Install combustion air flange and secure with screws

removed in step one.

N

ON

-D

IRECT

V

ENT

(S

INGLE

P

IPE

) P

IPING

Non-direct

vent

installations require only a vent/flue pipe. The

vent pipe can be run horizontally with an exit through the side of

the building or run vertically with an exit through the roof of the

building. The vent can also be run through an existing

unused

chimney; however, it must extend a minimum of 12 inches above

the top of the chimney. The space between the vent pipe and the

chimney must be closed with a weather-tight, corrosion-resistant

flashing.

Although

non-direct

vent

installations do not require a combustion

air intake

pipe

, a minimum of one 90° elbow should be attached to

the furnace’s combustion air intake

if

: an upright installation uses

the standard intake location, or a horizontal installation uses the

alternate air intake location. This elbow will guard against inad-

vertent blockage of the air intake.

V

ENT

/F

LUE

P

IPE

L

ENGTHS

AND

D

IAMETERS

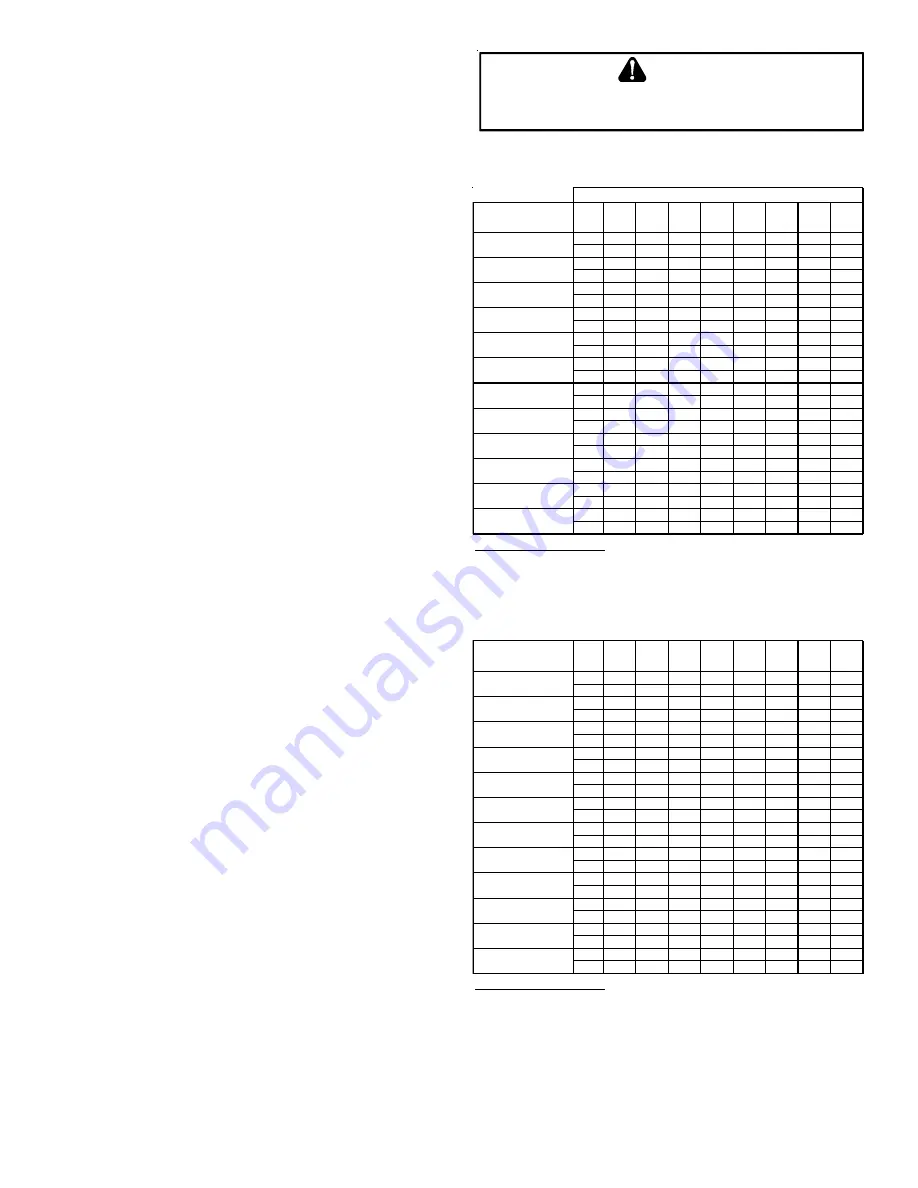

(For Installations At or Above 7,000 Feet using 3” Venting)

NOTE:

If either a 90 degree or 45 degree elbow is used for

termination, it must be pointed downward.

Refer to the Direct and Non-Direct Vent Table for applicable length,

elbows, and pipe diameter for construction of the vent/flue pipe

system of a non-direct vent installation. In addition to the vent/

flue pipe, a single 90° elbow should be secured to the combustion

air intake to prevent inadvertent blockage. The tee used in the

vent/flue termination must be included when determining the num-

ber of elbows in the piping system.

V

ENT

/F

LUE

P

IPE

T

ERMINATIONS

NOTE:

If either a 90 degree or 45 degree elbow is used for

termination, it must be pointed downward.

The vent/flue pipe may terminate vertically, as through a roof, or

horizontally, as through an outside wall.

Vertical vent/flue pipe terminations should be as shown in the fol-

lowing figure. Refer to

Vent/Flue Pipe and Combustion Air Pipe -

Termination Locations

for details concerning location restrictions.

The penetration of the vent through the roof must be sealed tight

with proper flashing such as is used with a plastic plumbing vent.

Horizontal vent/flue pipe terminations should be as shown in the

following figure. Refer to

Vent/Flue Pipe and Combustion Air Pipe.

To secure the pipe passing through the wall and prohibit damage to

piping connections, a coupling should be installed on either side of

the wall and solvent cemented to a length of pipe connecting the

two couplings. The length of pipe should be the wall thickness plus

the depth of the socket fittings to be installed on the inside and

outside of the wall. The wall penetration should be sealed with silicone caulking material.

NOTE: Terminate both pipes in the same pressure zone (same side of roof, no major obstacles between pipes, etc.).

B

E

SURE

NOT

TO

DAMAGE

INTERNAL

WIRING

OR

OTHER

COMPONENTS

WHEN

REINSTALLING

COUPLING

AND

SCREWS

.

CAUTION

MODEL

PIPE

SIZE

1

2

3

4

5

6

7

8

2

^

145

140

135

130

125

120

115

110

3

168

161

154

147

140

133

126

119

2

55

50

45

40

35

30

25

20

3

127

120

113

106

99

92

85

78

2

^

30

25

20

15

10

5

N/A

N/A

3

^

72

65

58

51

44

37

30

23

2

^

30

25

20

15

10

5

N/A

N/A

3

^

72

65

58

51

44

37

30

23

2

^

40

35

30

25

20

15

10

5

3

72

65

58

51

44

37

30

23

2

60

55

50

45

40

35

30

25

3

168

161

154

147

140

133

126

119

2

30

25

20

15

10

5

N/A

N/A

3

113

106

99

92

85

78

71

64

2

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

3

65

58

51

44

37

30

23

16

2

100

95

90

85

80

75

70

65

3

137

130

123

116

109

102

95

88

2

60

55

50

45

40

35

30

25

3

127

120

113

106

99

92

85

78

2

35

30

25

20

15

10

5

N/A

3

160

153

146

139

132

125

118

111

2

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

3

127

120

113

106

99

92

85

78

7,000 f t altitude or above use 3" pipe

^

*MSS920402BN - add 20' of 2" pipe for upflow position

^

*MSS920803BN - add 10' of 2" pipe for upf low position, add 66' of 3" pipe f or upflow position

^

*MSS920804CN - add 25' of 2" pipe for upf low position, add 58' of 3" pipe f or upf low position

^ *MSS920805CN - add 15' of 2" pipe for upflow position, add 58' of 3" pipe f or upf low position

MODEL

PIPE

SIZE

1

2

3

4

5

6

7

8

2

^

100

95

90

85

80

75

70

65

3

168

161

154

147

140

133

126

119

2

45

40

35

30

25

20

15

10

3

168

161

154

147

140

133

126

119

2

^

35

30

25

20

15

10

5

N/A

3

168

161

154

147

140

133

126

119

2

60

55

50

45

40

35

30

25

3

113

106

99

92

85

78

71

64

2

45

40

35

30

25

20

15

10

3

120

113

106

99

92

85

78

71

2

40

35

30

25

20

15

10

5

3

151

144

137

130

123

116

109

102

2

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

3

158

151

144

137

130

123

116

109

2

100

95

90

85

80

75

70

65

3

137

130

123

116

109

102

95

88

2

45

40

35

30

25

20

15

10

3

168

161

154

147

140

133

126

119

2

40

35

30

25

20

15

10

5

3

120

113

106

99

92

85

78

71

2

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

3

113

106

99

92

85

78

71

64

2

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

3

110

103

96

89

82

75

68

61

7,000 f t altitude or above use 3" pipe

^ *MSS960402BN - add 25' of 2" pipe for upflow position

^

*MSS960803BN - add 20' of 2" pipe for upf low position

Number of Elbows

*MSS920402BN

*MSS920603BN

*MSS921004CN

*MSS960603BN

*MSS920803BN

*MSS920804CN

*MSS920805CN

*CSS920804CN

*CSS921005CN

*MSS960402BN

*MSS921005CN

*MSS921205DN

*CSS920402BN

*CSS920603BN

*MSS960804CN

*MSS960805CN

*MSS961005CN

*CSS961005CN

*MSS960803BN

*CSS961205DN

*MSS961205DN

*CSS960402BN

*CSS960603BN

*CSS960804CN

*MSS9* / *CSS9 Direct Vent (2-Pipe) & Non-Direct Vent (1-Pipe)

Maximum Allowable Length of Vent/FLue Pipe