6

221788B

1 General Data

1.5 Gas Supply

The gas installation shall be in accordance with the current

issue of BS6891.

The supply from the governed meter must be of adequate size

to provide a steady inlet working pressure of 20mbar (8in wg) at

the boiler.

On completion test the gas installation for soundness using the

pressure drop method and suitable leak detection fluid, purge

in accordance with the above standard.

1.6 Electrical Supply

WARNING. This boiler must be earthed.

All system components shall be of an approved type and shall

comply with and be connected in accordance with the current

issue of BS7671 and any applicable local regulations.

Connection of the boiler and system controls to the mains

supply must be through a common isolator and must be fused

3A, maximum. This method of connection must be by a fused

double pole isolating switch, with a minimum contact separation

of 3mm on both poles. The switch should be readily accessible

and preferably adjacent to the appliance. It should supply the

appliance only and be easily identifiable as so doing.

Alternatively, an unswitched shuttered socket outlet and 3A

fused 3 pin plug both to the current issue of BS1363 may be

used, provided that they are not used in a room containing a

bath or shower.

Wiring to the boiler must be PVC insulated type to the current

issue of BS6500 Table 16, not less than 0.75mm

2

(24/0.20mm).

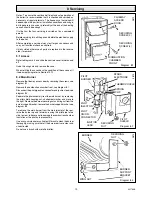

1.7 Contents of Packaging

There are two packs, one contains the boiler, refer to Section 4.1

for contents.

The other pack contains the balanced flue terminal assembly,

wall duct and flue hood assembly.

Refer to Section 2.3 to check that the flue terminal assembly

supplied is suitable.

1.8 Water System

This boiler shall only be used on an unrestricted open vented

system with the water supply taken from a feed and expansion

cistern having a head of 27m (90ft) maximum.

This boiler must not be connected to a sealed water system.

1.9 Drain

System

A draining tap must be provided at the lowest points of the

system which will allow the entire system, boiler and hot water

cylinder to be drained.

Draining taps should be to the current issue of BS2879.

Boiler

A draining point is fitted at the bottom right hand side of the heat

exchanger. Cover controls to avoid water damage. If required

remove the combustion chamber front cover to improve access.

RANGE RATING

NOMINAL

kW

HEAT

INPUT

(GROSS)

Btu/h

NOMINAL

kW

HEAT

OUTPUT

Btu/h

BURNER

m bar

SETTING

PRESSURE

in.w.g

APPROX

m

3

/h

GAS

RATE

ft

3

/h

TABLE 2.

7.52

9.25

10.99

25,650

31,575

37,500

5.86

7.33

8.79

20,000

25,000

30,000

5.5

9.1

12.7

2.2

3.7

5.1

0.72

0.89

1.06

25.5

31.5

37.5

min

medium

max

2.35Litre

(0.52gal)

44.5kg

(98lb)

34kg

(75lb)

DATA TABLE 1.

DATA LABEL

Bottom right hand side of case

ELECTRICITY

SUPPLY

WATER

CONNECTION

GAS

CONNECTION

WATER

CONTENT

LIFT WEIGHT

( I n c l u d i n g

Terminal)

TOTAL DRY

4 x 22mm copper pipes from

top of case

Rc

1

/

2

in.

230V~50Hz, fused 3A.

WEIGHT

BURNER INJECTOR MARKING: 203099

PILOT INJECTOR MARKING: 7215

1.10 Safety Valve

A safety valve need not be fitted to an open vented system.

1.11 Location

This boiler is not suitable for outdoor installation.

This boiler may be installed in any room, although particular

attention is drawn to the requirements of the current issue of

BS7671 with respect to the installation of a boiler in a room

containing a bath or shower. Any electrical switch or boiler

control utilising mains electricity should be placed so that it

cannot be touched by a person using the bath or shower.

The electrical provisions of the Building Standards (Scotland)

Regulations apply to such installations in Scotland.

The boiler must be mounted on a flat wall which is sufficiently

robust to take its total weight.