1

6

7

9

1

1

12

13

1

4

1

2

1

6

17

1

8

4

5

3

2

8

10

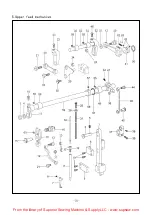

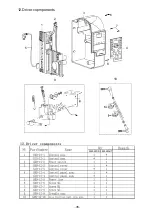

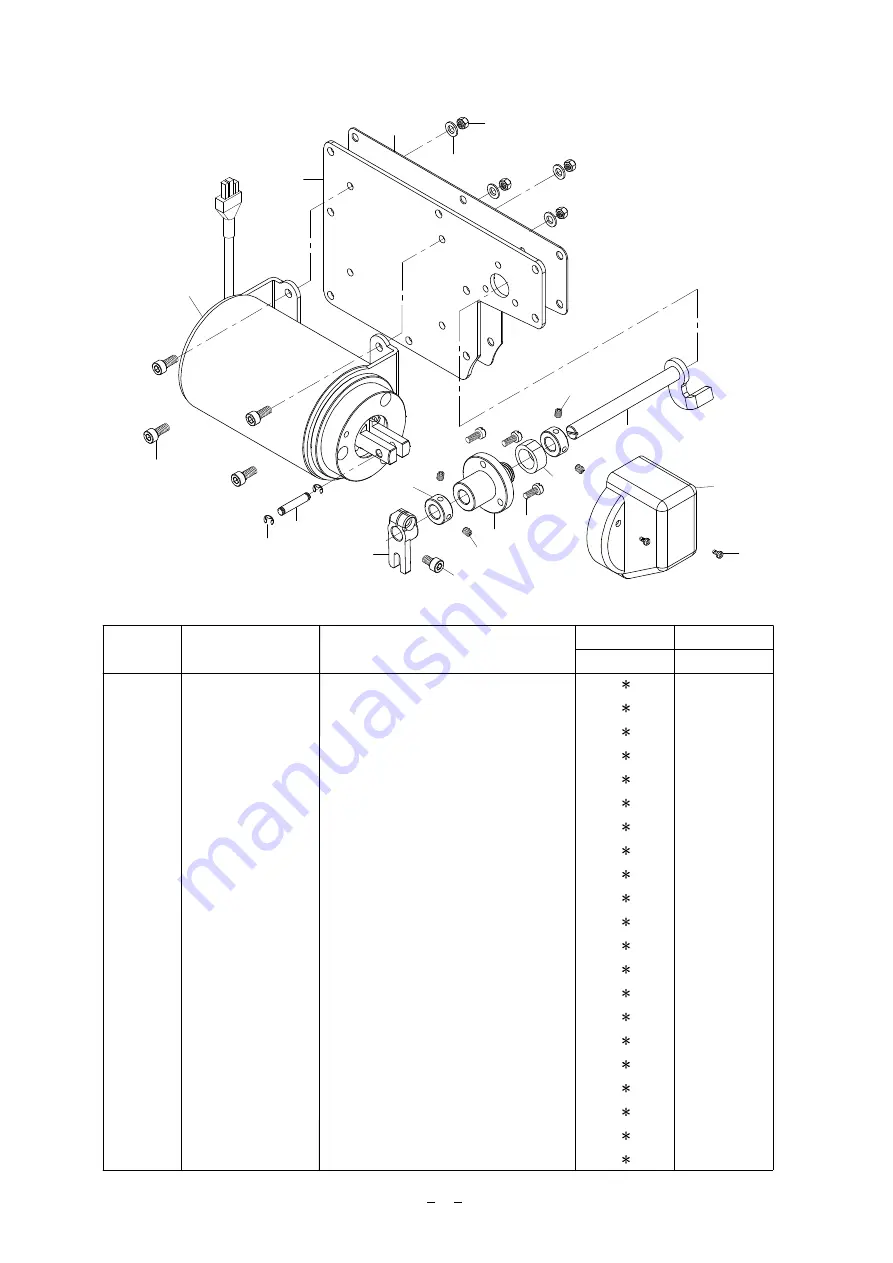

Ref.No

Part.No

Name of parts

Qty

Qty

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

17

16

G10-11-01

G10-11-02

G10-11-03

G10-11-04

G10-11-05

G10-11-06

G10-11-07

G10-11-08

G10-11-09

G10-11-10

G10-11-11

G10-11-12

G10-11-13

G10-11-14

G10-11-15

G10-11-16

G10-11-17

1

1

1

4

4

4

1

2

1

2

1

4

1

3

1

1

1

Electromagnet ASM

Side plate

Gasket

Washer

NUT M5

Screw M5 L=12

Connection pin

E-RING 4

Electromagnet crank

Thrust collar

Screw M5 L=8

Screw 11/64-40 L=5

Bushing

Screw M4 L=10

Nut of bushing M16-1.5

Transmission shaft

Electromagnet shield

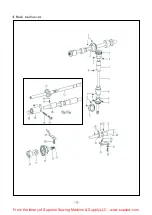

1

5

18

G10-11-18

2

Screw M4 L=5

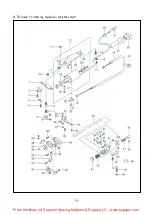

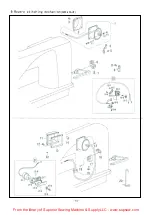

11.Presser foot lifting set mechanism(Option parts)

11.Presser foot lifting set mechanism(Option parts)

44

3955-45DD

3955-45AUT

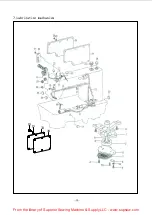

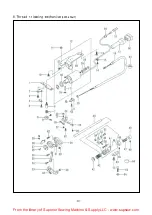

Содержание WF3955-45AUT Series

Страница 3: ...Operation Instruction From the library of Superior Sewing Machine Supply LLC www supsew com ...

Страница 21: ...Parts Manual From the library of Superior Sewing Machine Supply LLC www supsew com ...

Страница 38: ...33 34 7 Lubrication mechanism 34 From the library of Superior Sewing Machine Supply LLC www supsew com ...

Страница 51: ...OLOBAL GLOBALSEW COM ...