18

GC-1368N

4.

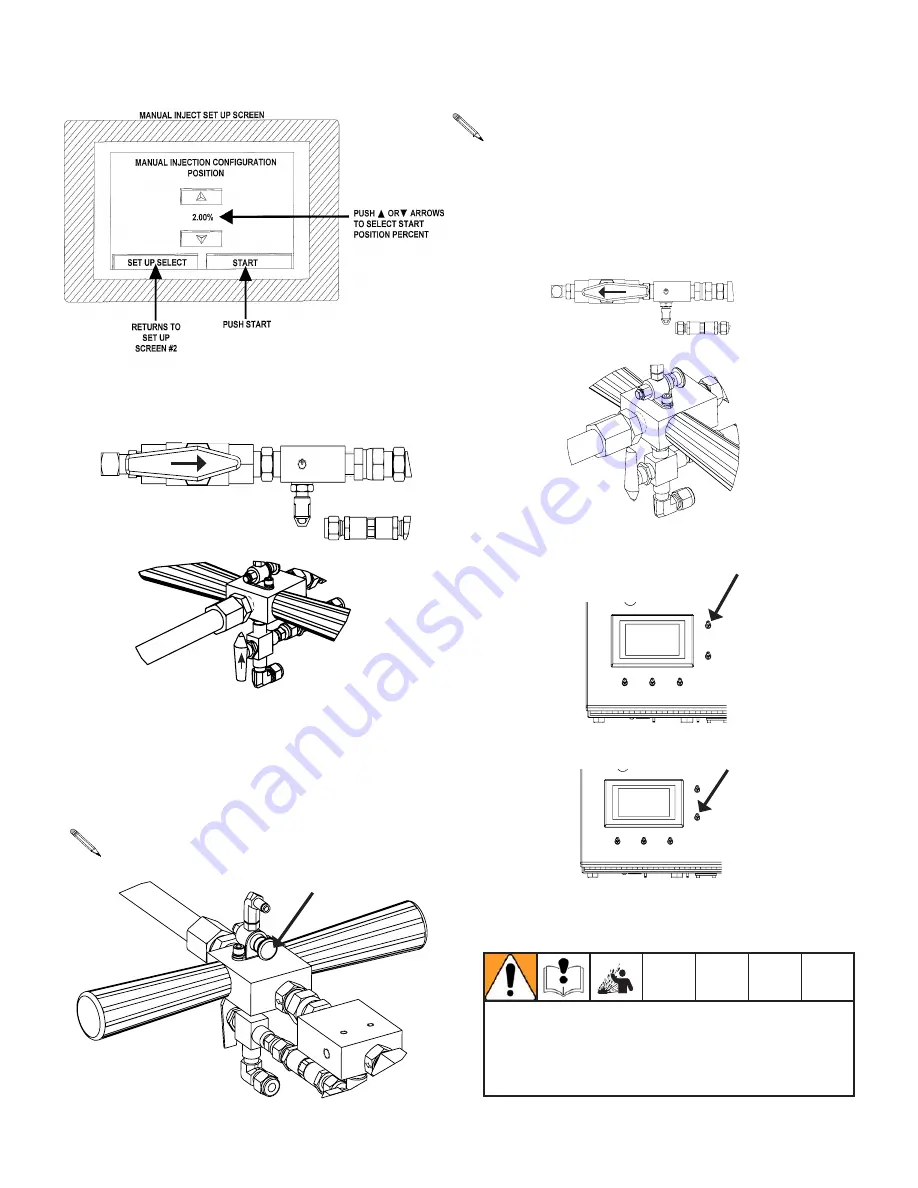

Turn the material and catalyst valves to the Injection

position.

5.

Depress the air switch button on the gun head to

dispense mixed material.

It’s strongly recommended

at this time to do a couple of test shots in a suitable

cup to confirm proper gel time.

When starting a new machine, it is recommended to

dispense a couple of strokes of resin into a suitable

container to ensure a proper flow of materials. This is

not required once the machine has been properly

wet-out.

6.

When finished, turn catalyst & resin valves

on the gun head to recirculation position.

BEFORE FLUSHING!

RESIN

CATALYST

7.

Flush the system.

a.

Press the Air Flush button.

b.

Press the Solvent Flush button.

c.

Press the Air Flush button again.

8.

Assure that proper catalyzation was achieved.

THE CATALYST PUMP WILL

THEN MOVE TO THE SELECTED

POSITION.

→

.025 gallons per stroke

95cc per stroke

Isocyanate Conditions

Rev. G 6/17/2008

21

Isocyanate Conditions

Material Self-ignition

Moisture Sensitivity of

Isocyanites

Isocyanites (ISO) are catalysts used in two component

foam and polyurea coatings. ISO will react with moisture

(such as humidity) to form small, hard, abrasive crystals,

which become suspended in the fluid. Eventually a film

will form on the surface and the ISO will begin to gel,

increasing in viscosity. If used, this partially cured ISO

will reduce performance and the life of all wetted parts.

To prevent exposing ISO to moisture:

•

Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere.

Never

store ISO in an open container.

•

Keep the ISO lube pump reservoir (if installed) filled

with Graco Throat Seal Liquid (TSL), Part 206995.

The lubricant creates a barrier between the ISO and

the atmosphere.

•

Use moisture-proof hoses specifically designed for

ISO, such as those supplied with your system.

•

Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

•

Never use solvent on one side if it has been contam-

inated from the other side.

•

Always lubricate threaded parts with ISO pump oil

or grease when reassembling.

Keep Components A and

B Separate

Foam Resins with 245 fa

Blowing Agents

Some foam blowing agents will froth at temperatures

above 90°F (33°C) when not under pressure, especially

if agitated. To reduce frothing, minimize preheating in a

circulation system.

Spraying materials containing isocyanates creates

potentially harmful mists, vapors, and atomized partic-

ulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient ventila-

tion in the work area. If sufficient ventilation is not

available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate per-

sonal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Some materials may become self-igniting if applied

too thickly. Read material manufacturer’s warnings

and material MSDS.

The amount of film formation and rate of crystalli-

zation varies depending on the blend of ISO, the

humidity, and the temperature.

NOTICE

To prevent cross-contamination of the equipment’s

wetted parts,

never

interchange component A (isocy-

anate) and component B (resin) parts.

Start-Up

When making test material dispenses or during flush

-

ing operation, make certain that dispensed material

and/or solvent is contained in a suitable container and

that this material and/or solvent is disposed of prop-

erly.

Changing Materials

22

Rev. G 6/17/2008

Changing Materials

•

When changing materials, flush the equipment mul-

tiple times to ensure it is thoroughly clean.

•

Always clean the fluid inlet strainers after flushing.

•

Check with your material manufacturer for chemical

compatibility.

•

Most materials use ISO on the A side, but some use

ISO on the B side.

•

Epoxies often have amines on the B (hardener)

side. Polyureas often have amines on the B (resin)

side.

Splatter Hazard

This section is used with some RAM plates which could get pushed out of the drums of sealant.

Burn Hazard

For equipment used with heated material.

WARNING

SPLATTER HAZARD

Hot or toxic fluid can cause serious injury if splashed in the eyes or on skin. During blow off of platen,

splatter may occur.

•

Use minimum air pressure when removing platen from drum.

WARNING

BURN HAZARD

- Hot Surfaces

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe burns:

•

Do not touch hot fluid or equipment.

•

Wait until equipment/fluid has cooled completely.

Isocyanate Conditions

Rev. G 6/17/2008

21

Isocyanate Conditions

Material Self-ignition

Moisture Sensitivity of

Isocyanites

Isocyanites (ISO) are catalysts used in two component

foam and polyurea coatings. ISO will react with moisture

(such as humidity) to form small, hard, abrasive crystals,

which become suspended in the fluid. Eventually a film

will form on the surface and the ISO will begin to gel,

increasing in viscosity. If used, this partially cured ISO

will reduce performance and the life of all wetted parts.

To prevent exposing ISO to moisture:

•

Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere.

Never

store ISO in an open container.

•

Keep the ISO lube pump reservoir (if installed) filled

with Graco Throat Seal Liquid (TSL), Part 206995.

The lubricant creates a barrier between the ISO and

the atmosphere.

•

Use moisture-proof hoses specifically designed for

ISO, such as those supplied with your system.

•

Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

•

Never use solvent on one side if it has been contam-

inated from the other side.

•

Always lubricate threaded parts with ISO pump oil

or grease when reassembling.

Keep Components A and

B Separate

Foam Resins with 245 fa

Blowing Agents

Some foam blowing agents will froth at temperatures

above 90°F (33°C) when not under pressure, especially

if agitated. To reduce frothing, minimize preheating in a

circulation system.

Spraying materials containing isocyanates creates

potentially harmful mists, vapors, and atomized partic-

ulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient ventila-

tion in the work area. If sufficient ventilation is not

available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate per-

sonal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Some materials may become self-igniting if applied

too thickly. Read material manufacturer’s warnings

and material MSDS.

The amount of film formation and rate of crystalli-

zation varies depending on the blend of ISO, the

humidity, and the temperature.

NOTICE

To prevent cross-contamination of the equipment’s

wetted parts,

never

interchange component A (isocy-

anate) and component B (resin) parts.

Содержание Spartan 3

Страница 12: ...12 GC 1368N 4 Push for set up screen Start Up ...

Страница 26: ...26 GC 1368N REVISION A 23280 02 SPARTAN 3 ASSEMBLY 01 Assembly Drawings ...

Страница 27: ...27 GC 1368N REVISION A 23280 02 SPARTAN 3 ASSEMBLY Assembly Drawings ...

Страница 28: ...28 GC 1368N REVISION A 23280 02 SPARTAN 3 ASSEMBLY Assembly Drawings ...

Страница 30: ...30 GC 1368N REVISION J 23250 00 SPARTAN 3 CONTROL BOX ASSEMBLY Sub Assembly Drawings ...

Страница 31: ...31 GC 1368N REVISION J 23250 00 SPARTAN 3 CONTROL BOX ASSEMBLY Sub Assembly Drawings ...

Страница 32: ...32 GC 1368N REVISION J 23250 00 SPARTAN 3 CONTROL BOX ASSEMBLY Sub Assembly Drawings ...

Страница 35: ...35 GC 1368N REVISION J 23250 00 SPARTAN CONTROL BOX SCHEMATIC Sub Assembly Drawings ...

Страница 43: ...43 GC 1368N REVISION P 23280 00 SPARTAN 3 W PAC ASSEMBLY 01 Accessories ...

Страница 44: ...44 GC 1368N REVISION P 23280 00 SPARTAN 3 W PAC ASSEMBLY Accessories ...