User Manual - P series

22

www.georgin.com

VII.

Maintenance

1. Inspection frequency

Inspection frequency depends on several criteria:

»

The mechanical and/or electrical working life of the microswitch

»

The mechanical working life of the sensing element

»

Frequency and conditions of operation of the instrument

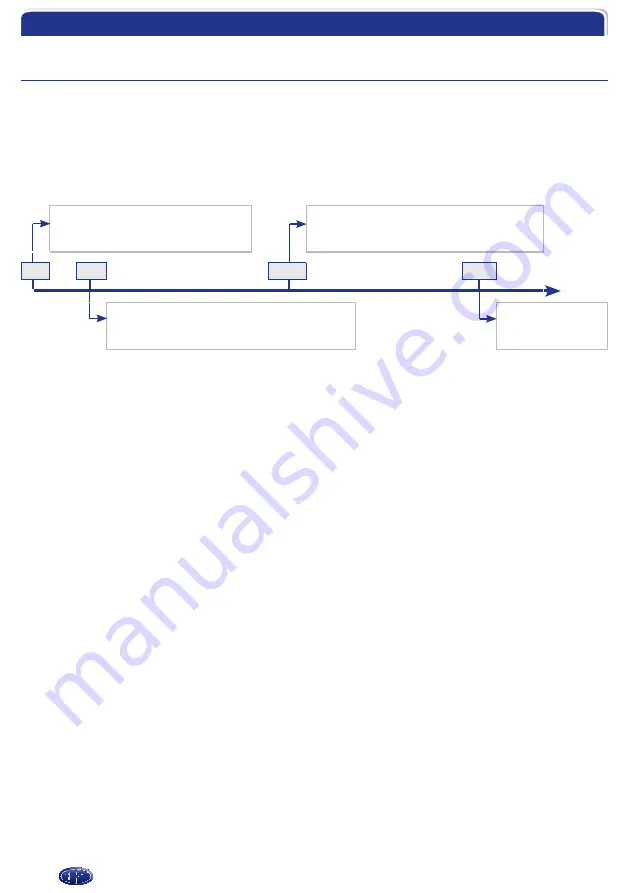

Georgin's standard* recommendation is to proceed as indicated:

1. Visual inspection of the instrument

(See Chapter II. Before installation)

2. Calibration

1. Visual inspection

2. Check cover seal

3. Checking / adjusting the calibration

0

1

6

12

Years

1. Visual inspection

2. Check cover seal

3. Checking / adjusting the calibration

1. Replacement to

be considered after

complete inspection

»

Year 0 :

1. Check that the paint has not been damaged, and check that there are no signs of deformation or impact

on the housing.

2. Calibration:

If the instrument is supplied adjusted: Check that the calibration is compliant, and readjust if necessary.

If the instrument is supplied unadjusted: Calibrate it according to the procedures given in this manual.

»

Year 1 :

After one year of standard operation, the mechanism can be considered to be run in. The following points

must therefore be checked:

1. Check that the paint has not been damaged, and check that there are no signs of deformation or impact

on the housing.

2. Open the cover and check that the cover seal is not damaged (cracks, etc.)

3. Check the calibration and adjust if necessary (applying the procedures given in this manual).

»

Year 6 :

After six years of standard operation, perform another inspection to ensure that the instrument is ageing well.

1. Check that the paint has not been damaged, and check that there are no signs of deformation or impact

on the housing.

2. Open the cover and check that the cover seal is not damaged (cracks, etc.)

3. Check the calibration and adjust if necessary (applying the procedures given in this manual).