S4000C

6

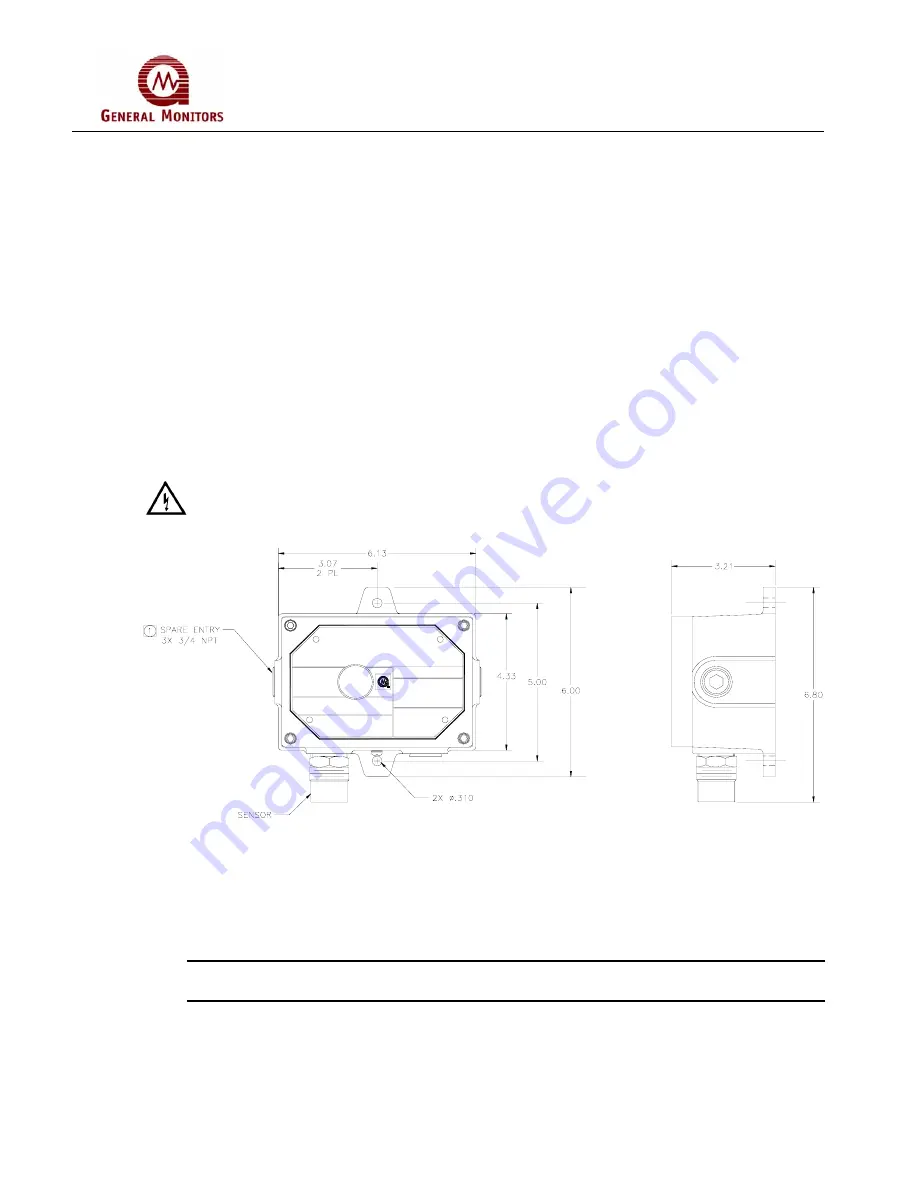

The overall and mounting dimensions for the Model S4000C (Figure 5) should be used when

making installation determinations. A complete list of the mechanical specifications can be

found in Section 9.3.2.

To prevent possible corrosion due to moisture or condensation, it is recommended that the

conduit connected to the Model S4000C housing be sealed, or contain a drain loop. Each

conduit run from a hazardous location to a non-hazardous location should be sealed so that

gases, vapors, and/or flames cannot pass beyond the seal. The purpose of seals in a Class I

hazardous location is to prevent the passage of gases, vapors, or flames from one electrical

installation to another through the conduit system.

It is not necessary to seal the Model S4000C housing to maintain its explosion-proof integrity;

however, conduit runs containing wires attached to the Model S4000C’s relay contacts must be

sealed (Section 3.5).

Information on Class I location seals can be found in the NEC, Article 501-5.

WARNING:

Acetic acid will cause damage to metal components, metal hardware, ceramic

IC’s, etc. If damage results from the use of a sealant that outgases acetic acid

(RTV silicone), the warranty will be void.

Figure 5: Outline and Mounting Dimensions

Once correctly installed, the Model S4000C requires little or no maintenance, other than

periodic calibration checks to ensure system integrity. General Monitors recommends that a

schedule be established and followed.

NOTE:

The system’s full two-year warranty will be voided if customer personnel or third parties

damage the system during repair attempts.

Sensor heads exposed to the elements may require the accessory mounting threads to be

lubricated. Grease must not be used. As an alternate, PTFE (Teflon) tape may be used on

sensor accessory threads.