27

SHENZHEN GETECH TECHNOLOGY CO., LTD

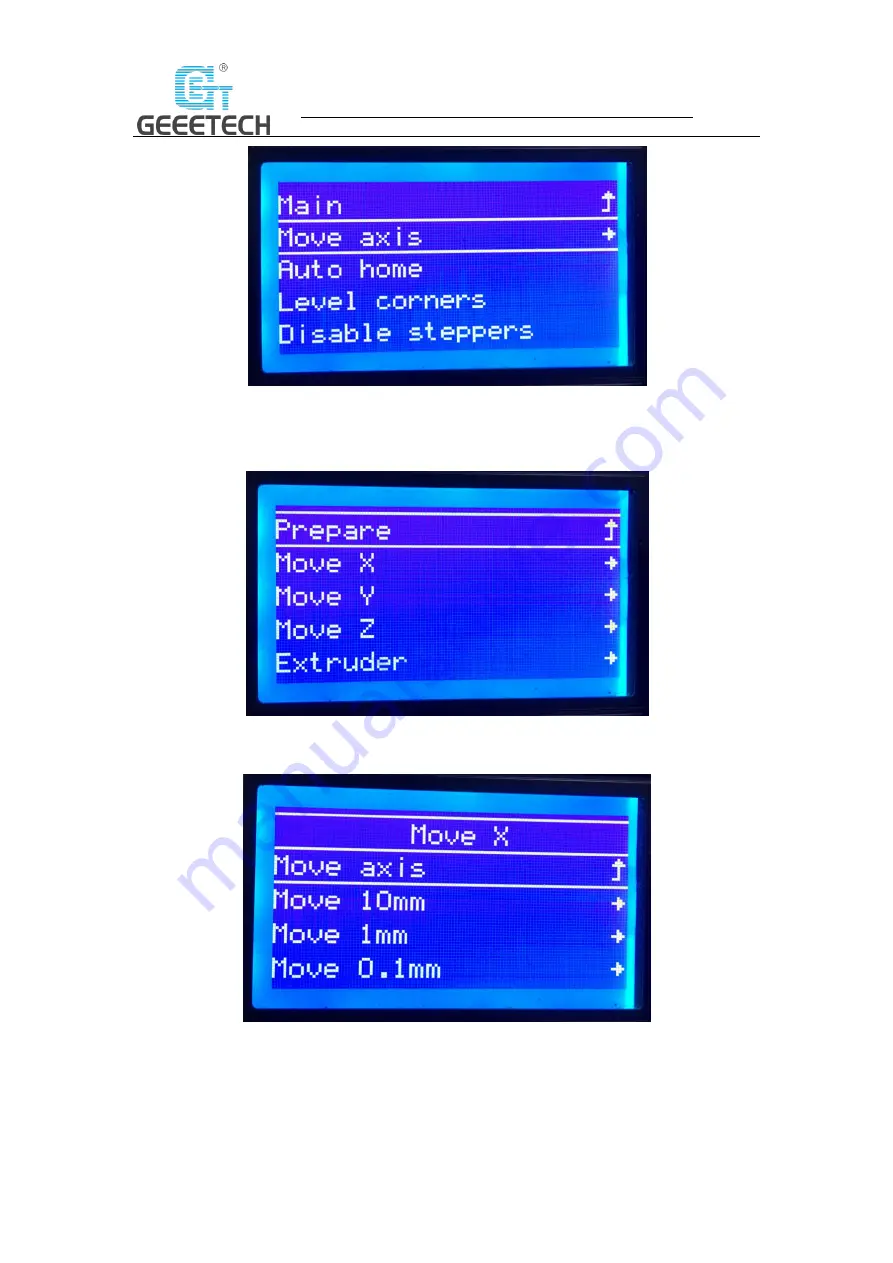

(Picture 7-22)

Choose from

“Move X/Y/Z/Extruder”

and rotate the knob to move them. See picture (7-23).

(Picture 7-23)

Choose

“Move 1mm”

, see picture (7-24).

(Picture 7-24)

Note: we suggest using 1mm to test X/Y/Z axis.

After axis’ testing finished, if you want to unlock the motor, choose

“Prepare>Disable steppers”

,

see picture (7-25).

Содержание A20T

Страница 1: ...1 SHENZHEN GETECH TECHNOLOGY CO LTD Geeetech A20T 3D Printer User Manual V1 00 ...

Страница 19: ...19 SHENZHEN GETECH TECHNOLOGY CO LTD Picture 6 13 ...

Страница 20: ...20 SHENZHEN GETECH TECHNOLOGY CO LTD 7 Introduction to the LCD menu 7 1 Tree diagram Picture 7 1 ...

Страница 48: ...48 SHENZHEN GETECH TECHNOLOGY CO LTD Picture 9 7 Picture 9 8 Picture 9 9 Picture 9 10 ...

Страница 54: ...54 SHENZHEN GETECH TECHNOLOGY CO LTD Shenzhen Getech Technology Co ltd www geeetech com ...