3

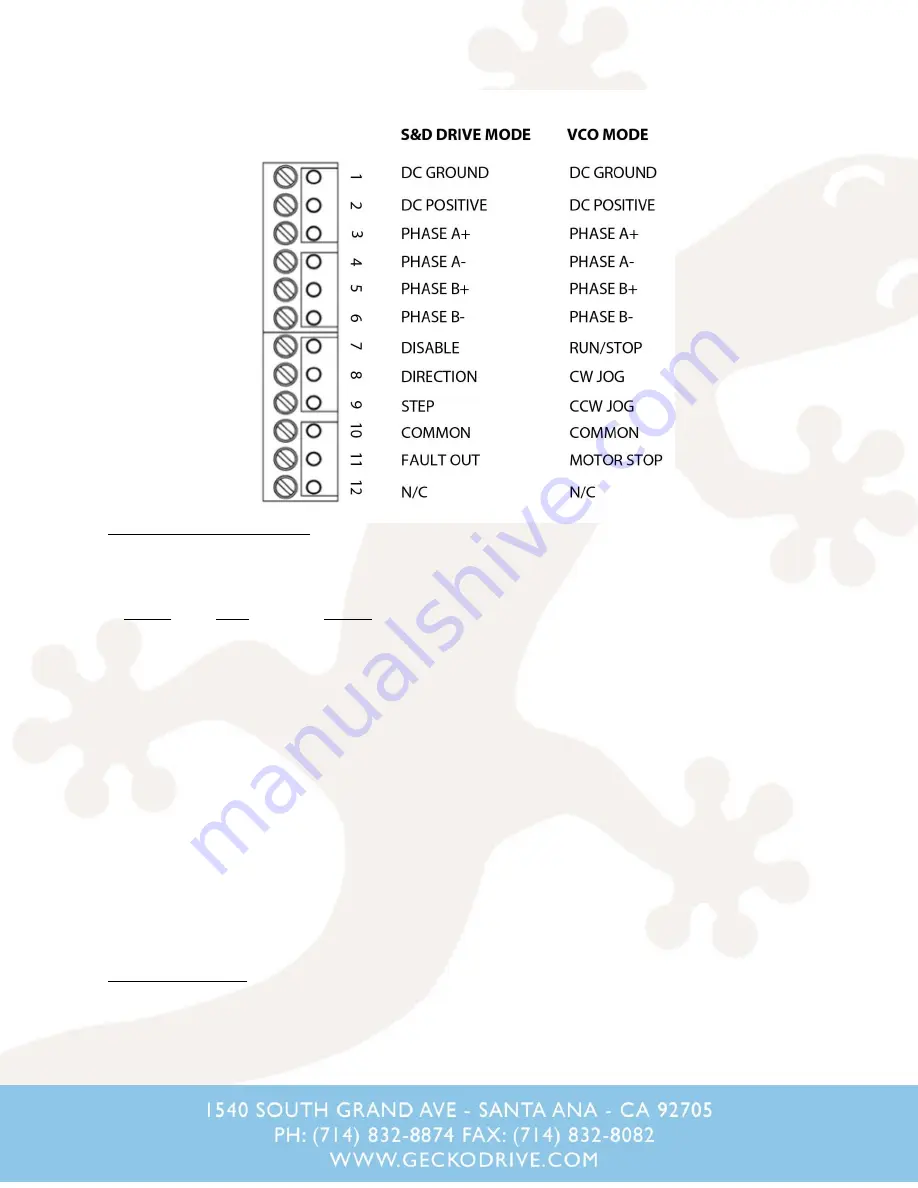

POWER CONNECTOR ASSIGNMENTS

The terminal connection is broken into two blocks of six connections, with the first six being power and motor connections.

Terminal

Name

Function

1

GND

DC Power supply (-)

2

VDC+

DC Power supply (+)

3

A

Motor winding A

4

/A

Motor winding A

5

B

Motor winding B

6

/B

Motor winding B

TERMINAL 1: DC GROUND

Connect the power supply '-' to this terminal. This connection must be hard-wired to the power supply.

TERMINAL 2: DC POSITIVE

Connect the power supply '+' to this terminal. The power supply voltage must be between 18 VDC and 80 VDC and this

connection must be hard-wired to the power supply. Do not use a switch, relay contact or any other device in series with this

wired connection.

TERMINAL 3: PHASE A+

TERMINAL 4: PHASE A-

TERMINAL 5: PHASE B+

TERMINAL 6: PHASE B-

TRIMPOT ADJUSTMENTS

TRIM1 and TRIM2 are used to maximize motor smoothness at speeds below 50 RPM. The Digital Self-Test feature can useful in

making these adjustments. While the motor is turning, adjust TRIM1 for minimum motor vibration.

The rest of this user's manual is divided into two sections. Use the

G216 STEP MOTOR DRIVE MANUAL

if the G216 is used as a

conventional step motor drive. Use the

G216 VCO MANUAL

if the G216 VCO is used.

Содержание G216

Страница 1: ...1 G216 MANUAL STEP MOTOR INDEXER...