D

GB

F

E

3

96458-03.2019-DGb

Contents

Page

3

Areas of application

8

3.1 Refrigerants

3.2 Oil charge

3.3 Limits of application

4

Compressor assembly

10

4.1 Storage and transportation

4.2 Setting up

4.3 Connecting the pipelines - solder system

4.4 Connecting the pipelines - cutting ring system

4.5 Pipes

4.6 Flange shut-off valves (HP/LP)

4.7 Option: cutting ring screw joint (HP/LP)

4.8 Laying suction and pressure lines

4.9 Operating the shut-off valves

4.10 Operating mode of the lockable service connections

4.11 Suction pipe filter

5

Electrical connection

15

5.1 Information for contactor and motor contactor selection

5.2 Standard motor, designed for direct or part winding start

5.3 Basic circuit diagram for part winding start

5.4 Electronic trigger unit INT69 G

5.5 Connection of the electronic trigger unit INT69 G

5.6 Functional test of the electronic trigger unit INT69 G

5.7 Oil sump heater

6 Commissioning

22

6.1 Preparations for start-up

6.2 Pressure strength test

6.3 Leak test

6.4 Evacuation

6.5 Refrigerant charge

6.6 Start-up

6.7 Pressure switch

6.8 Decompression valves

6.9 Avoiding slugging

6.10 Filter dryer

7 Maintenance

26

7.1 Preparation

7.2 Work to be carried out

7.3 Accessories

7.4 Spare parts recommendation

7.5 Lubricants

7.6 Decommissioning

8

Technical data

28

9

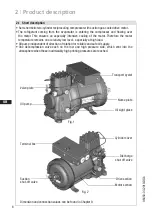

Dimensions and connections

29

10 Declaration of installation

31

11 Service

32

Содержание Bock HGX2 CO2 T Series

Страница 33: ...D GB F E 33 96458 03 2019 DGb ...