D

GB

F

E

13

96031-11.2011-DGbFEI

INFO!

Mechanical start unloader with bypass solenoid is not required.

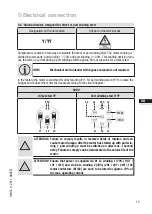

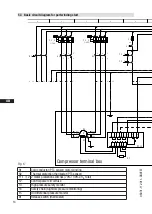

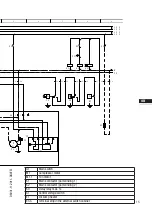

In the factory, the motor is switched for direct starting (YY). For part winding start (Y/YY), remove the

bridges and connect the motor feed cable according to the circuit diagram.

L1

L2

L3

L1

L2

L3

L1

L3

L2

PTC

PW

II

PW

I

PTC

400 V

Direct start YY

Part winding start Y/YY

5

|

Electrical connection

5.2 Standard motor, designed for direct or part winding start

Designation on the name plate

Sticker on the terminal box

Y/YY

Compressors marked in this way are suitable for direct or part winding start. The motor winding is

divided into two parts: part winding 1 = 70% and part winding 2 = 30%. This winding devision redu

-

ces the start-up current during a part winding start to approx. 65% of the value for a direct start.

ATTENTION! Failure to comply results in reversed fields of rotation and can

cause motor damage. After the motor has started up with part win-

ding 1, part winding 2 must be switched on after max. 1 second

delay. Failure to comply can be detrimental to the service life of the

motor.

ATTENTION! Ensure that power is supplied via K1 to winding 1 (70%) (1U1 /

1V1 / 1W1) and via K2 to winding 2 (30%) (2U1 / 2V1 / 2W1). The

motor contactors (K1/K2) are each to be rated for approx. 70% of

the max. operating current.