CB Watch 3 User Manual

v6.3 - May 2019

Page 76 of 100

Setting Pump Alarms

Notice:

It is the customer’s responsibility to

decide whether to set alarms or not and to

decide what thresholds to set alarms at, as this will depend on the customer’s

operational priorities and risk philosophy. However, here are some guidelines that may

prove helpful in deciding what threshold values to use:

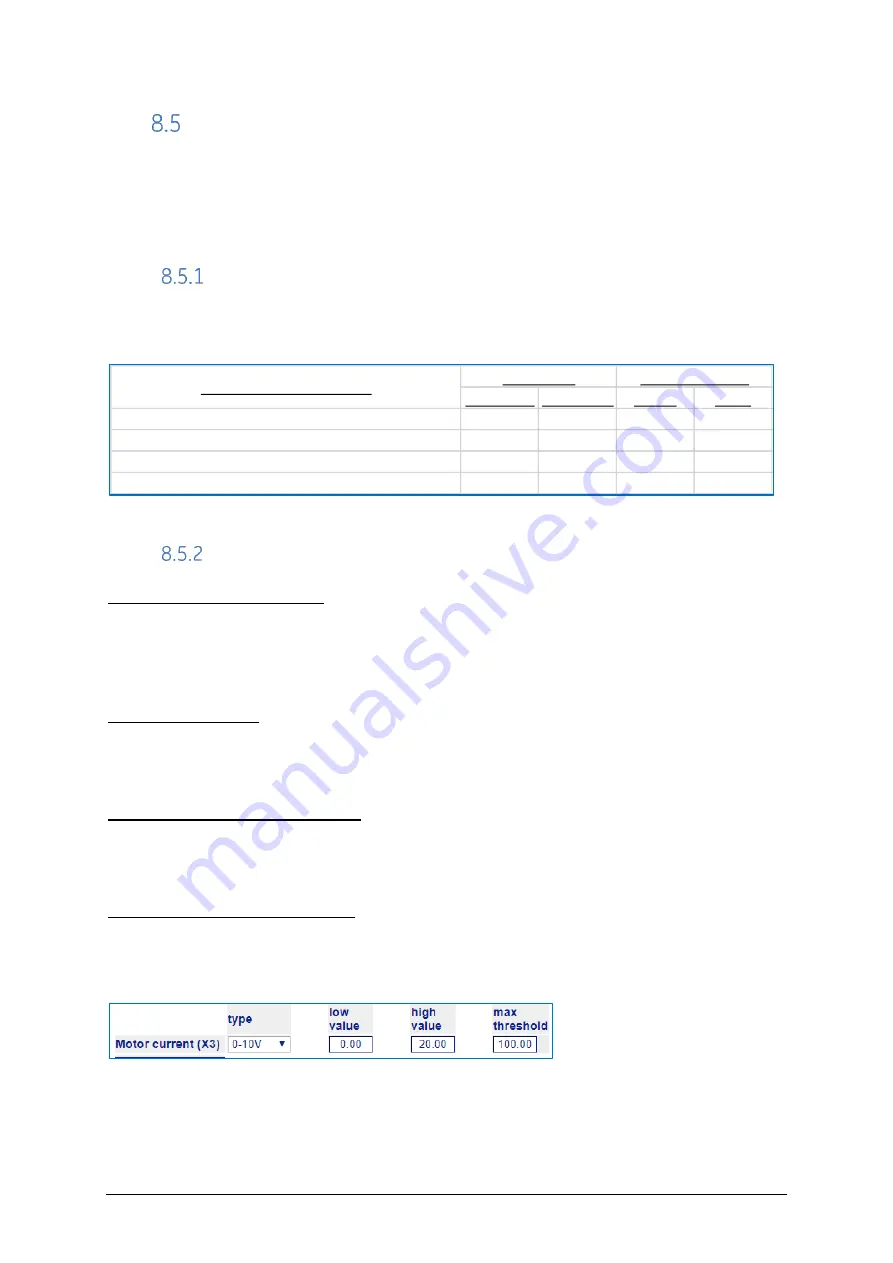

Alarm summary

This table summarises all the alarms that can be set for monitoring the

hydraulic/pneumatic energy storage mechanism:

Figure 128

–

Pump based energy storage mechanism alarms

Alarm thresholds

Number of pump starts /24h

In some instances, an engineered leak ensures that the pump starts every couple of

days, so this should be considered. Depending on how often the breaker is supposed to

operate, more than 2 or 3 pump starts per day should be flagged.

Pump run time /24h

Depending on how long the pump cycle takes (typically 15-20minutes), the pump run

time should not exceed 60 minutes per day.

Cumulative pump motor run time

Data is usually available from the motor’s maintenance manual. A possible value

could

be 12,000 min (200 hr), but it depends on the motor type.

Peak pump motor inrush current

Data is usually available from the motor’s maintenance manual. A possible value could

be 50A, but it depends on the motor type.

To avoid any alarms set as follows:

Min Alarm Max Alarm

Digital

Relay

Number of pump starts /24h

No

Yes

Yes

Yes

Pump run time /24h

No

Yes

Yes

Yes

Cumulative pump run time

No

Yes

Yes

Yes

Pump motor inrush current

No

Yes

Yes

Yes

Data obtained from CBW3

Thresholds

Alarms available