20/24

EN

PREPARATION

Use only cylinder connections appropriate for the type of gases used according to DIN 477.

CONNECTION TO THE CYLINDER

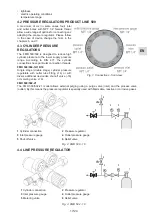

Fig. 9: Tighting the union nut with a spanner

1.

First screw the union nut onto the cylinder by hand. Pay

attention to right- and left-handed threads! Align the

regulator. Do not tilt it when setting it on!

2.

Tighten the union joint with the appropriate open-end

spanner. Do not use spanner extensions!

INSTALLATION OF OUTLET TUBES

Tubes are usually assembled with tube fittings. Assembly

starts inserting the tube completely into the fitting. Then screw

the union nut by hand and tighten the nut with a spanner

(1 1/4 turns). Please take care to follow the manufacturers

instructions and the compatibility of gas type/pressure with

materials.

EXTERNAL GAS PURGING FMD 500/502-21

Use corrosive, flammable or oxidizing gases and f. e. the

cylinder pressure regulator FMD 500/502-21, you have to

purge the unit with external gas before installation, startup

end ending operation.

Cylinder pressure regulators with external gas purging make it possible to: dry the fitting and/or

remove damp atmospheric air which may have entered the station before start-up or when changing

cylinders, purge out toxic, corrosive or pyrophoric gases from the fitting before changing cylinders

and before ending operation.

Dry purging gas N2 or Ar 5.0 of 4 - 10 bar is required for successful purging..

1.

Check that purging lines (7) and exhaust lines (5) are connected correctly.

2.

Close all valves of the fitting (handle at right angles to pipe).

3.

Turn the handwheel of the pressure regulator (2) as far as possible anticlockwise - through passage is

thus closed.

4.

Open the purge gas inlet valve (7).

5.

Open the pressure regulator (2) partially by turning the handwheel approx. two revolutions clockwise.

6.

Close the purge gas inlet valve (7). Allow the purging gas which has now flowed into the pressure

regulator to remain there for a few seconds.

7.

Open the process gas outlet valve (5) briefly and allow the purging gas to escape. Then close the process

gas outlet valve (5) again immediately.

8.

Repeat steps 4., 6. and 7. between five and seven times.

9.

Close all valves of the station. Close the pressure regulator (2) completely by turning the handwheel

anticlockwise.

6.2 LINE AND SUPPLY PRESSURE REGULATORS

PREPARATION

Release the gas pressure, purge if necessary with inert gas (see VBG 50). Then open the pipelines with

special tools, avoiding turnings. Make sure the lines and connection pieces are in clean, impeccable

condition.

CONNECTION

Line and supply pressure regulators are usually delivered with tube fittings. Installation requires complete

insertion of the pipeline into the connection. Then screw on the union nut by hand and tighten it (1 1/4 turns)

with an open-end spanner.

START-UP

When connecting or changing cylinders containing toxic or corrosive gases, appropriate personal

protection measures must be taken (respiratory protection, eye protection and protective clothing).

Observe the MAK values (maximum workplace concentration value; see Technical norms for

dangerous substances, TGRS 900) and have the correct respiratory protection filters at hand.

+

+

7.

Содержание druva LINE 200

Страница 12: ......