32

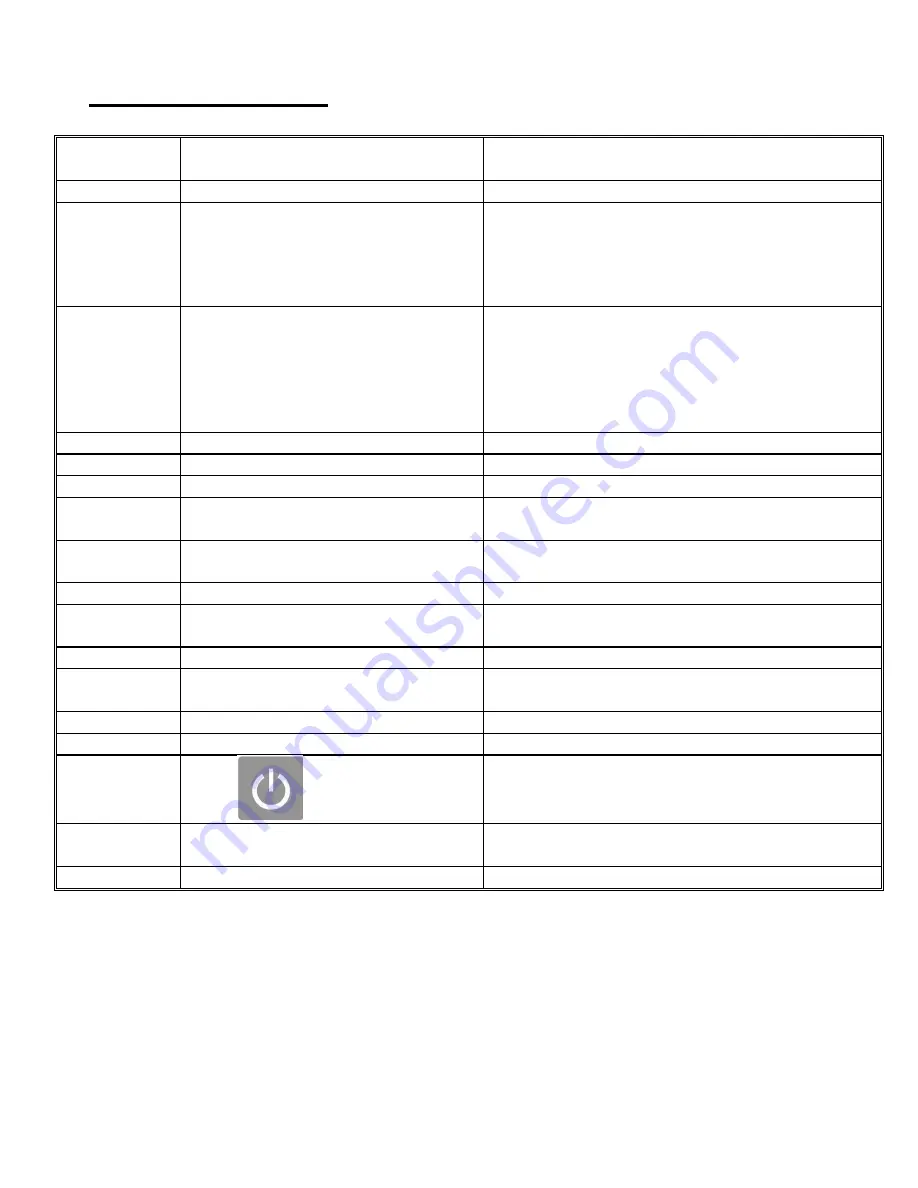

11. Trouble Shooting Guide

Error

Message

Symptom and Possible Cause

Action

E001

Press

“Start” no feed

Load paper into the hopper

E002

1 Paper does not reach to S2

2 Undesired paper under S2 when

power on the feeder

1.1 Correct skew, readjust side guide

1.2 Check media not flat or curled

1.3 Sensor #2 dirty

1.4 Adjust the Level Sensor height

2. Remove the paper

E003

1 Paper does not reach S3.

2 Sensor 3 detect infraRed

1.1 Readjust side guide

1.2 Check media quality

1.3 Clean Sensor 3 if needed

1.4 Adjust the Level Sensor height

2 Clear paper out

3 Block the Infra Red source

E004

Feed Tray keeps going down

Level Sensor failed

E005

S3 seeing paper too long

Remove jamed paper in Exit Sensor

E006

Suction Fan no On/Off function

Suction Fan On/Off Index Sensor failed

E007

Paper cannot reach to Sure Feed

Sensor

1. Lever Sensor too low, adjust the senor height

2. Sure Feed Sensor failed

E008

Sensor 8 keeps seeing Actuator

1. Sure Feed Sensor Trigger malfunction

2. Sure Feed Sensor failed

Ld Er

Cover not closed or in place

Close the cover

db Er

Double feed.

1. Adjust the level sensor lower

2. Raise separator

dA Er

Test Run is not complete

Press “Test Run” again

tP Er

Feed tray up to suction head then

down without feeding

Sensor 4 Level Sensor failed

“- -“

Feed tray stop at upper limit

Feed tray empty and reach to top mrgin switch

“----“

Feed tray stop t the lowest limit

Feeder tray reaches top margin switch

Blinking

“□□□□”

Press

doesn’t feed

1. Coater not ready

2. Inline interface has problem, check interface

cable pin to pin in sync

Error can not

reset

1. Exit sensor sensed the Infra Red

2. Paper path has paper

1.Try to cover the sensor to block the Infra Red

2. Remove the sheet in paper path

No Power

E-stop is ON

Reset E-stop

Содержание Laser Pro DFS

Страница 1: ...DFS Auto Feeder Installation Operation Manual Revision 04 08 2021 ...

Страница 7: ...www GCCworld com 7 5 Name Plate ...

Страница 10: ...www GCCworld com 10 d Align the autofeeder with the lower panel Upper Panel Lower Panel Lower Panel ...

Страница 15: ...www GCCworld com 15 f Put the bule PC window back g DFS Auto Sheet Feeder installation is completed ...

Страница 22: ...www GCCworld com 22 m Put back the blue PC window n Intallation of Media Collection Tray is completed ...