Section 3: OPERATION

3.10 Starting a Welch Dry Vacuum Pump

Before attaching the pump to a system it is well to familiarize yourself with the function and action of

the pressure vacuum pump which you have acquired. Review the power requirements as described

in Section 2.6. Welch recommends running the pump for a few minutes to warm it up before use. The

warm-up improves the pumps ability to pass water and organic vapor. A warm pump will handle more

vapor without liquefying it than a cold pump.

3.11 Cleanliness

Take every precaution to prevent foreign particulates or liquid from entering the pump. Particulates will

damage the pump’

s performance. If you fi nd that particulates or liquid will come off during the process

of evacuation, a simple liquid trap can be made out of readily available material for protecting the pump.

The trap would consist of a fi ltering fl ask placed between the pump and the vacuum chamber.

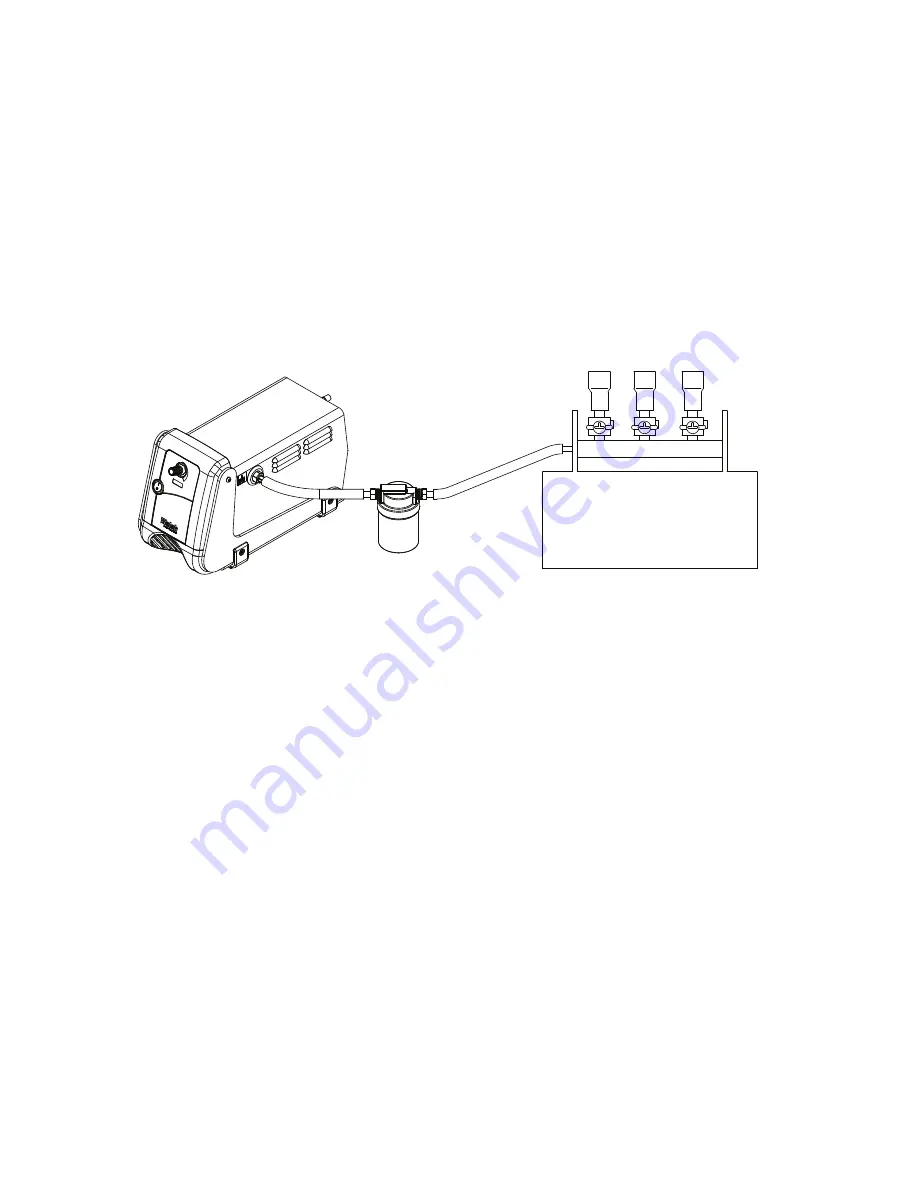

Dry Vacuum Pump

Liquid Trap

Filtration Manifold

3.12 Leak Detection

Eliminating all leaks in a vacuum system is a key to obtaining maximum vacuum. The pump must

remove this added volume of leaked gas to maintain the desired vacuum. Leaks can be located by

slightly pressuring the system and painting the suspected area with a thick soap solution. Escaping air

will produce soap bubbles.

3.13 Operating Pressure Range

Vacuum pumps are designed to be run from slightly below atmospheric to their maximum vacuum level

on the intake side. Consult the Specifi cation Table in the back of this manual for the ratings for your

model.

3.14 The Effects of Unwanted Vapor

Systems which contain undesirable vapors cause diffi culty both from the standpoint of attaining

desirable ultimate pressures. A vapor is defi ned as the gaseous form of any substance which is usually

a liquid or a solid. Water, oil, and mercury vapors are three of the more common vapors encountered in

typical vacuum systems. When such vapors exist in a system, the vapors or mixtures of gas and vapors

are subject to condensation within the pump; the precipitated liquid may thus ultimately solidify on the

PTFE heads and diaphragm causing corrosion.

3.15 Shutdown Procedures

After use, Welch recommends the pump be run for about 2 minutes disconnected from the vacuum

process. The air pumped through the mechanism will purge out water vapor or droplets of condensate

that may have formed on the inside of the pump. This purge of the pump mechanism helps prevent

build up of solute crystals inside of the pump head. Over time, these crystals will shorten pump lifetime.

10