Installing the Tensioner

Remove the button head screw and washer

located at the end of the tensioner bar with

the 3 mm hex wrench provided. Slide the

tensioner onto the bar, being careful to align

the bar with all of the bearings and the drive

gear with the gear track. Replace the screw

and washer into the end of the tensioner bar.

Note: The tensioner bar is equipped with a

tensioner travel stop to limit travel of the

tensioner along the bar.

ASSEMBLY INSTRUCTIONS

Support Post Installation (cont’d)

Place the support post onto the central slot

of the turntable. With your fingers placed

through the large hole in the underside of the

turntable, press the mounting plate against

the inside top surface of the turntable while

aligning the hole in the support post with the

hole in the mounting plate and fix them with

the mounting bolt. Repeat procedure on to

attach the support post on the opposite side

of the turntable.

4

Travel Stop

Tensioner Travel Stop

The tensioner bar is equipped with a tensioner

travel stop to limit travel of the tensioner

along the bar and prevent contact between

the tensioner and the racquet mounting sys-

tem while stringing. The travel stop is lo-

cated about midpoint along the tensioner bar

below the gear track.

To disengage the stop, pull and hold the

knob, rotate 90 degrees and release. To

engage the stop, repeat the above proce-

dure until the travel stop pin protrudes be-

yond the opposite surface of the tensioner

bar.

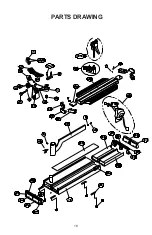

Содержание X-Stringer

Страница 17: ...16 NOTES...

Страница 19: ...18 PARTS DRAWING...