12

Tension Calibration Procedure

If you suspect that your Progression ESII is not pulling the correct

tension, you should check the tension with a Tension Calibrator which

provides a measurement of the actual pulling tension being applied by

the machine.

With the machine set for the fast pulling speed, and the tension set at

20 lbs., place one end of a calibrator equipped with synthetic string into

a string clamp. Place the opposite end into the string gripper and apply

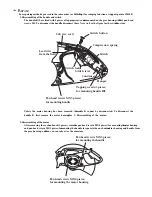

tension. If the measured tension is inaccurate, remove the rectangular

cover from the L.E.D. display cover plate cover. Rotate screw (“Low

LBs”) in small increments until the displayed tension matches the

tension indicated on the calibrator. Set the machine tension to 80 lbs.

and apply tension to the calibrator. If the measured tension is innacurate,

rotate screw (“High LBs”) in small increments until the displayed tension

matches the tension indicated on the calibrator. Since adjustment of the “Low LBs” screw at 20 lbs can influence the tension at 60

lbs and visa versa, repeat these steps until the set tension matchs the tension reading of the calibrator at both 20 and 60 lbs. Replace

the rectangular cover in the L.E.D. display cover plate.

Please note that there will be a range of tension from the maximum tension at which the tensioner stops pulling (high end of the range),

to the minimum tension at which the tensioner starts pulling again (low end of the range). This difference between the high and low

end of the range can vary from 2-4 lbs depending on the string used to calibrate the machine and the speed of the tensioner. For

consistency, we recommend that the tension setting of the machine be calibrated as close as possible to the high end of the range,

using the fast pulling speed and a synthetic string, which is the method used at the factory. Using this method will be the most

consistent and will also insure that the racquet will not be over tensioned.

MAINTENANCE and ADJUSTMENTS

2

6 .0

High KGs

High LBs

Low LBs

Low KGs

Units

Selection

Switch

LBs

KGs

Содержание Progression ES II

Страница 16: ...15 EXPLODED PARTS VIEW...