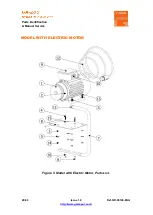

Parts Identification

& Manual Service

15/40

Issue 1.0

WARNING!

Before proceeding, follow the Pressure Relief Procedure

outlined previously in this manual. Additionally, follow all other warnings

to reduce the risk of an injection injury, injury from moving parts or

electric shock. Always unplug the sprayer before servicing.

DAILY MAINTENANCE

Two daily procedures are required for routine operator maintenance on this unit:

•

Lubricating the upper packing.

•

Cleaning the rock catcher.

Lubricating the Upper Packings

•

Clean out the paint that has seeped past the upper packings into the packing oil

reservoir above the fluid section.

•

Fill the packing oil reservoir 1/2 full with Piston Lube supplied by the factory. This will

extend packing life.

NB:

Do not over -fill the reservoir so that it overflows and drips into the paint.

MAINTAINING THE HYDRAULIC SYSTEM

CAUTION!

Use of Hydraulic Fluid DIN 51524 standard, section 1 & 2 (for

example ISO VG 46) is mandatory in the hydraulic system. Do not use any

other hydraulic fluid. Use of any other hydraulic fluid may seriously

damage the hydraulic system and will void the warranty.

1.

Check the hydraulic fluid daily. It should be at the “Full” mark on the dipstick. If it is low,

add only Hydraulic Fluid DIN 51524 standard, section 1 & 2 (for example ISO VG 46).

Never add or change hydraulic fluid except in a clean, dust-free area. Contamination of

the hydraulic fluid will shorten hydraulic pump life and may void warranty.

2. Change the hydraulic fluid every twelve months. Drain the old fluid from the tank. Start

the unit at just enough pressure to operate the fluid section. Run the unit at this low

pressure for at least 5 minutes. This removes air from the system. Check the fluid level

after this procedure.

3. The hydraulic system has an external, replaceable hydraulic filter. Change the filter

every twelve months.

MAINTENANCE