22

01.02.2021

Cod. 80006380a - GB

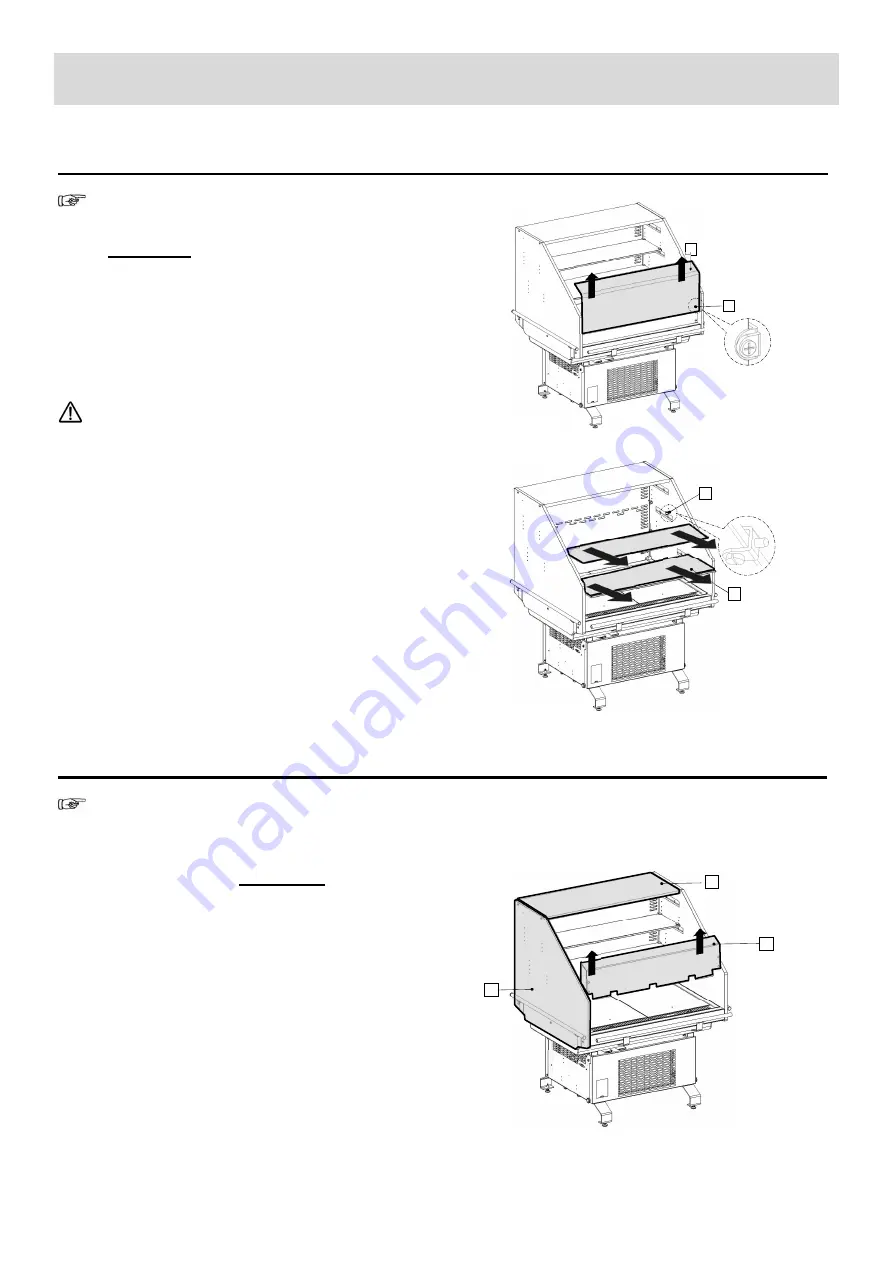

7.3 Cleaning glass shelves and front glass

____________________________

Use a soft and non

-

abrasive cloth with neutral de-

tergents (pH 6÷8) for cleaning and a soft and dry cloth for

drying.

Do not use

abrasive products or metal scrapers

that may scratch the glass. Do not use acid

-

based prod-

ucts or ammonia

-

based products, bleach or alcohol.

Do not use corrosive detergents, thinners, alcohol or sol-

vent which can damage the plastic seals and the painted

parts of the frame.

Do not use hot water on cold glass as it can break

and be dangerous for the operator.

To remove the glasses, proceed as follows:

•

To extract the front glass [1]. Unscrew the glass

stopper screw [2], if any. Extract the glass from the

profile slot and lift it up from both sides.

•

To extract the glass shelves [3]. Remove the glass

holder screw [4]. Extract the glass shelves remov-

ing them from both sides.

•

Reposition the pieces by following the reverse or-

der.

7.4 Cleaning of the acrylic glass parts

____________________________

Use soft microfiber or cotton cloth soaked with

lukewarm water (max. 35° C). If there are halos, add

some neutral diluted detergent (pH 6÷8). Rinse and dry

with a soft and dry cloth.

Do not use

corrosive deter-

gents, thinners, alcohol or solvents.

For cleaning completely the acrylic glass parts:

•

Extract the front glass following the instructions in

section 7.3.

•

Extract the air intake air baffle [1].

2

1

3

1

2

4

3

7. User’s Maintenance