3

/

10 pages

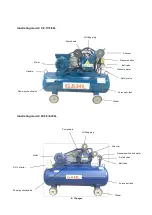

1. INTRODUCTION

Read this manual carefully before operating or servicing the air compressor, to familiarize

yourself with proper safety, operation and maintenance procedures. FAILURE TO COMPLY WITH

INSTRUCTIONS IN THIS PRODUCT MANUAL COULD RESULT IN PERSONAL INJURY, PROPERTY

DAMAGE AND OR VOIDING YOUR WARRANTY. Following the instruction in this manual will

make your air compressor runs safer with longer product life.

2. SAFETY GUIDANCE

DANGER- AN IMMEDIATE HAZARD THAT WILL CAUSE SERIOUS INJURY OR LOSS OF LIFE.

1) TO REDUCE THE RISK OF THE FIRE OR EXPLOSION, NEVER SPRAT FLAMMABLE LIQUIDS

IN A CONFINED AREA. It is normal for the motor and the pressure switch to produce sparks while

operating, if sparks come into contact with vapors from gasoline or other solvent, they may

ignite causing fire or explosion, Always operate the air compressor in a well ventilated area, Do

not smoke while spraying. Do not spray where sparks or flame are present, Keep compressor

away from spraying area as far as possible.

2) DISCONNECT POWER SUPPLY AND RELEASE ALL PRESSURE FROM THE SYSTEM

BEFORE ATTEMPTING TO INSTALL, SERVICE, RELOCATE OR PERFORM ANY MAINTENANCE

OF THE AIR COMPRESSOR.

3) Electric motor and D.O.L Starter must be securely and adequately connected with earthing

wires to prevent of electric shock risks.

4) Do not weld on the air tank of this air compressor. Welding on the air compressor tank may

cause an extremely hazardous conditions. Welding on the tank in any manner will void the

warranty.

5) Never use an electric air compressor outdoors when it is raining or on a wet surface, as it

may cause an electric shock.

6) Never directly inhale the compressed air produced by the air compressor. It is not suitable

for breathing purposes.

7)

This air compressor starts automatically. ALWAYS shut off the air compressor, remove air

pipe connection from air outlet ball valve and releasing all air pressure from the system before

servicing the air compressor.

8) Check the manufacturer’s maximum pressure rating for the air tools and accessories.

Compressor outlet pressure must be regulated so as to never exceed the maximum pressure of