B

B

X

X

/

/

B

B

X

X

G

G

-

-

1

1

0

0

0

0

0

0

S

S

e

e

r

r

i

i

e

e

s

s

G

G

r

r

o

o

o

o

v

v

e

e

M

M

e

e

a

a

s

s

u

u

r

r

e

e

m

m

e

e

n

n

t

t

G

G

a

a

g

g

e

e

O

O

p

p

e

e

r

r

a

a

t

t

i

i

o

o

n

n

M

M

a

a

n

n

u

u

a

a

l

l

23

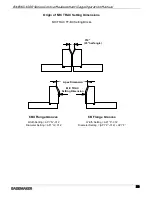

Zeroing the BXG-1000 Gage Using Gage Blocks

Materials Needed:

•

BXG-1000 gage

•

MIC Over Ball Setting Dimensions Table

•

Gage blocks

To ensure consistent and accurate readings, the BXG-1000 gage should be zeroed on gage

blocks once during each shift, at a minimum.

1. Locate the dimension for the type of groove

you are measuring in the MIC Over Ball

Setting Dimensions table in this manual.

2. Stack the gage blocks to the proper

measurement.

3. Turn the rear contact point lock knob, located

on the top of the gage, to loosen the contact

point holder.

4. Turn the contact point adjustment knob,

located at the rear of the gage, to adjust the

location of the rear contact point.

5. Continue turning the adjustment knob until the

contact points fit between the gage blocks.

6. Lock the rear contact point lock knob.