8

9/11 REV. 7/13

OVERHAUL

WARNING

:

DISCONNECT TOOL FROM ITS POWER SOURCE BEFORE PERFORMING OVERHAUL

If a tool is performing sluggish or leaking, a complete overhaul may be necessary. Service Kit 248001

(GB2480) and 248002 (GB2480A) contains a complete set of o'rings, back-up rings and screws.

Perform overhaul in a clean, well-lit area using care not to scratch or nick any smooth surface that comes in

contact with an o'ring. Use of Lubriplate® (Gage Bilt part no. 402723) or another lubricant is recommended

during reassembly to prevent tearing or distorting of o'rings.

Disconnect hydraulic hoses (206119-2) and electrical cord (206136) or air line (240123) from powerunit. Re-

move couplers (585038 & 585047) from hoses (206119-2) and drain. Push piston (248011) back into handle

(248004) to empty all fluid from tool. Push piston (248011) back to the front of cylinder. Remove cap

(248019) and deflector (756120) from cylinder.

Push piston (248011)` back until rear gland assembly (248017) falls out of cylinder. Push piston (248011) fur-

ther back and guide it out the rear of the cylinder. Slide relief valve (248013) from piston (248011). Use an

arbor to push wiper (405843), front gland ass’y (248006) and polyseal (405818) out the rear of the cylinder

taking care not to mar cylinder bore. Using a small blunt object, remove o'rings and back-up rings from

components.

Clean parts in mineral spirits or other o'ring compatible solvent, being sure to clean o'ring grooves. Inspect

components for scoring, excessive wear or damage.

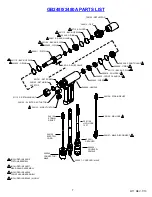

Reassembly sequence is opposite of disassembly. Be sure relative positions of o'rings and back-up rings

are as shown in exploded view and parts list. Relief valve (248013) must be installed with four flats towards

the rear and must enter notch in the rear of adapter. Coat hose fitting threads with a non-hardening Teflon®

thread compound such as Slic-tite® (Gage Bilt part no. 403237). Apply hot glue to wire connections to en-

sure wires DO NOT contact each other or handle ass’y.

IMPORTANT:

Be sure to use thread sealant on all hydraulic fittings, Loctite® 30534 or similar

Teflon infused pipe dope if recommended.

CAUTION:

Teflon tape is an

excellent thread sealer. If it is not properly applied, however, pieces may enter

the hydraulic system and cause malfunctions and damage. Use 1 1/2 wraps of

tape on each thread. Cut off all loose tape ends. Tighten until fitting feels snug

and then go 1/2 to a full turn past that point.

CAUTION:

Over tightening can

easily distort the threads.