12

4. Start-up and use

–

Check for correspondence between the compressor plate

data with the actual specifications of the electrical system. A

variation of ± 10% with respect of the rated value is allowed.

–

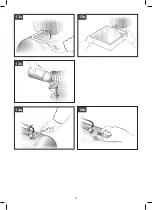

Insert the plug of the power cable in a suitable socket (

pic. 6

)

checking that the button of the pressure switch located on the

compressor is in the OFF «O» position.

–

Check the oil level by means of the oil dipstick (

pictures 7a-

7b

), and if necessary top up.

–

At this point, the compressor is ready for use.

–

Operating on the switch of the pressure switch (

pic. 1

), the

compressor starts, pumping air into the receiver through the

delivery pipe.

–

When the upper calibration value (set by the manufacturer)

has been reached, the compressor stops, venting the excess

air present in the head and in the delivery pipe through a valve

located under the pressure switch.

This facilitates subsequent restart due to the absence of

pressure in the head. When air is used, the compressor restarts

automatically when the lower calibration value is reached (2

bar between upper and lower).

–

The pressure in the receiver can be checked on the gauge

provided (

pic. 8

).

–

The compressor continues to operate according to this automatic

cycle until the switch of the pressure switch is turned.

–

Always wait at least 10 seconds from when the compressor

has been switched off before restarting this.

–

All compressors are fitted with a pressure reducer. Operating

on the knob with the tap open (turning it in a clockwise direction

to increase the pressure and in a counterclockwise direction

to reduce this,

pic. 9a

), air pressure can be regulated so as

to optimize use of pneumatic tools. After setting the value

required, the ring-nut underneath must be tightened to fasten

the knob (

pic. 9b

).

–

The value set can be checked on the gauge.

–

Please check that the air consumption and the maximum

working pressure of the pneumatic tool to be used are

compatible with the pressure set on the pressure regulator

and with the amount of air supplied by the compressor.

–

Always pull out the plug and drain the receiver once you have

completed your work (

pictures 10-11

).

5. Cleaning and maintenance

Warning!

Pull the power plug before doing any cleaning and mainte-

nance work on the appliance (pic. 10).

Warning!

Wait until the compressor has completely cooled down.

Risk of burns!

Warning!

Always depressurize the tank before carrying out any

cleaning and maintenance work (pic. 11).

Cleaning

Never clean the machine and its components with solvents,

flammable or toxic liquids. Us only a damp cloth making sure

you have unplugged the compressor from the current outlet.

Maintenance

–

BEFORE CARRYING OUT ANY OPERATION, ALWAYS

PULL OUT THE PLUG AND DRAIN THE RECEIVER

COMPLETELY (pictures 10-11).

–

Check that all screws (in particular those of the head of the unit)

are tightly drawn up (torque 10 Nm = 1.02 Kgm).

The control must be performed before the first start-up of the

compressor and subsequently before the first intensive use in

order to restore the correct closing torque value modified as a

result of heat expansion.

–

After loosening any safety screws, clean the intake filter

according to the type of working environment and at least every

100 hours (

picture 12

). If necessary, replace the filter element

(clogging of the filter reduces compressor performance and an

inefficient filter causes increased wear).

–

Replace the oil after the first 100 hours of operation and every

300 hours subsequently (

pictures 13a-13b-13c

). Remember

to check the oil level at regular intervals.

Use

SAE 40

. (For cold climates,

SAE 20

is recommended).

Never mix different grade oils. If the oil changes color (whitish

= presence of water; dark = overheated), it is good practice to

replace the oil immediately.

–

Periodically (or after working with the compressor for more

than an hour), drain the condensate that forms inside the

receiver (

pic. 11

) due to the humidity in the air. This protects

the receiver from corrosion and does not restrict its capacity.

–

Spent oil and condensate MUST BE DISPOSED OF in

accordance with environmental protection regulations and

current legislation.

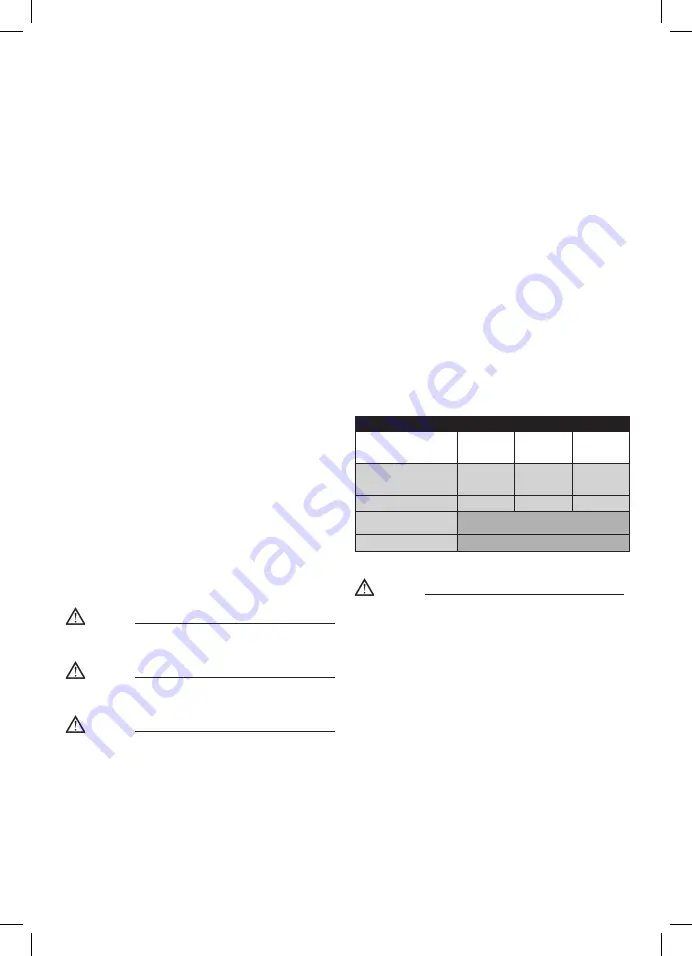

TABLE 1 – MAINTENANCE

FUNCTION

AFTER THE

FIRST 100

HOURS

EVERY 100

HOURS

EVERY 300

HOURS

Cleaning of intake filter and/

or substitution of filtering

element

•

Change of oil

•

•

Tightening of head tension

rods

At start-up and after the first hour of work

Draining tank condensate

Periodically and at the end of work

Warning!

If the water that condenses is not drained, it may corrode

the receiver, reducing its capacity and impairing safety.

As it is a contaminating product, condensate must be DIS-

POSED of in accordance with laws on protection of the en-

vironment and current legislation.

The compressor must be disposed in conformity with the

methods provided for by local regulations.

Safety valve

The safety valve has been set for the highest permitted pressure

of the pressure vessel. It is prohibited to adjust the safety valve

or remove its seal. Actuate the safety valve from time to time to

ensure that it works when required. Pull the ring with sufficient

force until you can hear the compressed air being released.

Then release the ring again.

Содержание 501755411

Страница 7: ...7 3a 4 1 ON 2 OFF 3b a c b e d 6 5b 5a...

Страница 8: ...8 7b 7a 8 9a 9b 10 11 12...

Страница 9: ...9 14a 13a 13b 13c 14b...

Страница 26: ...26 KIT FXA FC24 1 8 KW 1 4 m 20 dB...

Страница 27: ...27 5 C 40 C 4 5 1 5 2 S3 25 2 5 7 5 1 2 2 3 a b c d e 4...

Страница 29: ...29 5 14a 14b 1 100 100 300...

Страница 42: ...42...

Страница 43: ...43...