Indication offset

Allows to compensate an eventual variation of pressure readings caused by sensor replacement.

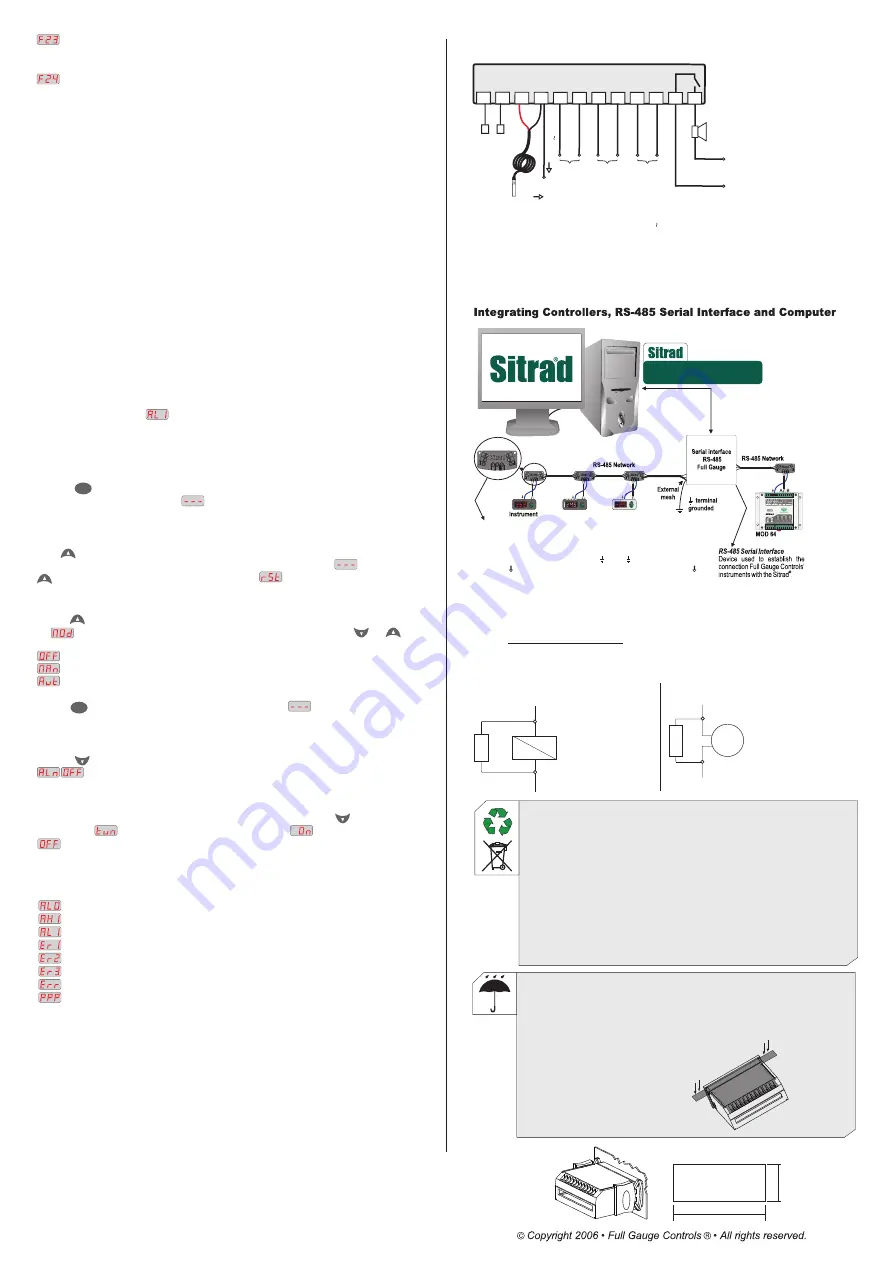

RS485 network controller address

®

Device address in the network for communication with Sitrad software application.

Warning:

it is not allowed to have more than one device with the same address in a network.

5. AUTOTUNING

The

AutoPID

plus

uses the Critical Period method to calculate automatically its PID parameters. This

method consists in making the system temperature oscillate around the setpoint so that the necessary

data can be collected to adjust the controller. The user must input two parameters for the method to work

properly: Temperature Hysteresis (F09) and Output Amplitude (F08). Both parameters must be chosen

to permit a recognizable oscillation around the setpoint. The autotuning operation time will vary for each

response from the system. Systems with a bigger cooling/heating capacity will have quicker responses

and the autotuning function will finish the data collection quicker.

The method for starting the autotuning can be configured in the function F11 and may operate in the

following modes:

Manual activation:

The autotuning can be activated either through the controller keyboard or through

®

the Sitrad software.

When activating the automatic control:

The autotuning will be executed every time the controller

enters the automatic control mode (PID).

Temperature not steady:

The autotuning will be executed every time the temperature does not

stabilize inside the time period programmed in the function F12.

When activating the automatic control and the temperature is not steady:

The autotuning will be

executed every time the controller enters in the autotuning mode and when the temperature does not

stabilize inside the time period programmed in the function F12.

If an error occurs during the system data collection, the controller will interrupt the autotuning and emit

an alarm with the message . Then it returns to the operation mode set before the autotuning

activation.

6. EASY ACCESS FUNCTIONS

6.1 - Proportional output value indication

Press the key shortly for displaying the current proportional output value. The percentage value will

be displayed followed by the indication .

SET

6.2 - Minimum/Maximum temperature indication

Press shortly to display the minimum/maximum temperature. When pressing the key, the message

will be displayed indicating the sensor temperature followed by the indication . If you hold the

key pressed, the values are restarted and the message is displayed.

6.3 - Controller operation mode selection

Hold the key pressed for 4 seconds to choose the controller operation mode. After pressing the key,

the message will be displayed followed by the current operation mode. Use the and keys

to choose one of the following options:

Controller OFF

Controller in the manual mode

Controller in the automatic mode

Use the key to confirm the selection and wait the message indicating that the setting is

finished.

6.4 - Canceling the active alarms

Press the key shortly to cancel the indication of current active alarms. After pressing the key, the

message is displayed and all the current active alarms will be deactivated.

SET

6.5 - Autotuning manual activation/deactivation

You can activate or deactivate the PID parameter autotuning by holding the key pressed for 2

seconds. The message will be displayed followed by the message (for activating) or

(for deactivating). When manually activating the autotuning, its starting conditions described in

item 5 will not be tested.

7 - DISPLAY MESSAGES

Low temperature alarm

High temperature alarm

Autotuning error

Indicates the autotuning was not completed after 12 hours.

Indicates an error occurred in the parameter calculation during the autotuning.

Indicates an error occurred in the temperature reading during the automatic control.

Temperature sensor disconnected or out of range

Invalid parameters configuration

The outputs are turned off automatically in this situation

Please check which parameters have invalid data configured and correct them to return to

normal operation

Open collector

8. CONNECTION

4

5

6

7

8

9 10 11 12

3

2

1

2

1

Se

ns

or

90 264V

ac (50/60Hz)

GND

12V Output

Red

0 10Vdc

Black

ALRM

For a current higher than the specified value,

use a power relay for activating the alarm.

RS

48

5 S

er

ial

co

m

m

un

ica

tio

n

Proportional voltage output

Proportional PWM output

Power supply

Alarm power

supply

T

o the terminal of

the distribution box

A

B

IMPORTANT

According to the chapters from the IEC60364 standard:

1:

Install protectors against over voltage on power supply

2:

Sensor cables and computer signals can be together, however not at the same place where power

supply and load wires pass for

3:

Install suppresor of transient in parallel to loads to increase the usefull life of the relays

Wiring diagram of suppresors in contactors

Suppresor

A1

A2

A1 e A2 are the

contactor coils.

Wiring diagram of suppresor for direct drive

Load

Suppresor

For direct activation the maximum

specified current should be taken

into consideration.

ENVIRONMENTAL INFORMATION

Package:

The packages material are 100% recyclable. Just dispose it through specialized

recyclers.

Products:

The electro components of Full Gauge controllers can be recycled or reused if it is

disassembled for specialized companies.

Disposal:

Do not burn or throw in domestic garbage the controllers which have reached the end-of-

life. Observe the respectively law in your region concerning the environmental

responsible manner of dispose its devices. In case of any doubts, contact Full Gauge

controls for assistance.

PROTECTIVE

:

VINYL

This adhesive vinyl (included inside the packing) protects the instruments against

water drippings, as in commercial refrigerators, for example. Do the application after

finishing the electrical connections.

Remove the protective paper

and apply the vinyl on the entire

superior part of the device,

folding the flaps as indicated by

the arrows.

Dimension of the clipping

for setting of the instrument

in panel

29 mm

72 mm

A

A

B

B

A B

A

B

A

B

A

B

OUT

1

OUT 2

OUT 3

PCT-400R plus

OUT 4

ALMR

A

A

B

B

A B

A

A

B

B

A B

A

A

B

B

A B

A

A

B

B

A B

PUMP

AUX

1

AUX 2

MICROSOL II plus

*Connecting Block for Serial Communication

Used to connect more than one instrument to the Interface. The wire's connections must

be made in agreement with the following rules: terminal

A

of the instrument connects to

the terminal

A

of the c

, that must be connected with the terminal

A

of the

Interface. Repeat the action for terminals

B

and

, being

the cable shield.

onnecting block

the terminal

must be connected to the respective terminals of

each instrument.

of connecting block

Keep Sitrad updated in website:

http://www.sitrad.com

®

*Sold Separately