PART NO. 9374318148

500

600

700

800

900

1000

1100

1200

1300

0

20

40

60

80

100

120

140

160

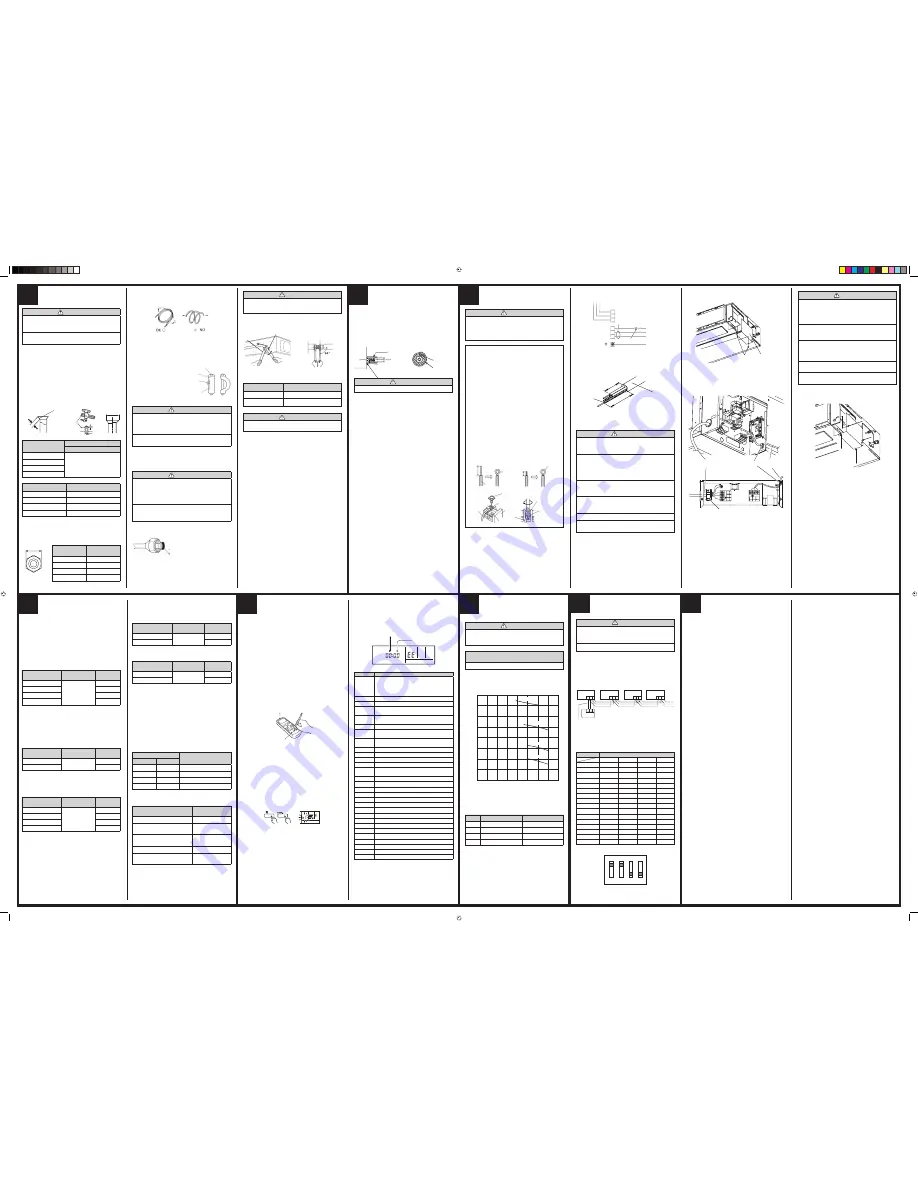

AIR FLOW (m

3

/h)

EXTERNAL STATIC PRESSURE (Pa)

Mode

4

High

Mode

3

High

Mode

2

High

Mode

1

High

CAUTION

Do not bundle the remote controller cord, or wire

the remote controller cord in parallel, with the

indoor unit connection wire (to the outdoor unit)

and the power supply cord. It may cause errone-

ous operation.

3. CONNECTION PIPES

Indoor unit

(1) Detach the caps and plugs from the pipes.

CAUTION

1

To prevent breaking of the pipe, avoid sharp

bends.

Bend the pipe with a radius of curvature of 150

mm or over.

2

If the pipe is bent repeatedly at the same place,

it will break.

CAUTION

1

Do not use mineral oil on

fl

ared part. Prevent

mineral oil from getting into the system as this

would reduce the lifetime of the units.

2

While welding the pipes, be sure to blow dry

nitrogen gas through them.

Transmitter section

Test run button

CONNECTING THE

PIPE

When bending the pipe, do not

bend it as is. The pipe will be

collapsed. In this case, cut the

heat insulating pipe with a sharp

cutter as shown on the right, and

bend it after exposing the pipe.

After bending the pipe as you

want, be sure to put the heat

insulating pipe back on the pipe,

and secure it with tape.

Pipe

Heat insulating

Pipe

Cutter

Cut line

Flare nut tightening torque

2

Strip 25 mm

Loop

Insulation

Strip 10 mm

Round

terminal

Round

terminal

Screw with

special washer

Screw with

special washer

Round terminal

Wire

Wire

Terminal block

Terminal

board

B. Strand wire

A. Solid wire

ELECTRICAL WIRING

4

1. CONNECTION DIAGRAMS

3

2

1

3

2

1

Remote controller

Red

White

Black

Red

White

Black

Power line

Control line

Outdoor unit

Indoor unit

side terminal

2. BENDING PIPES

The pipes are shaped by your hands. Be careful not to collapse

them.

Extend the pipe

by unwinding it

Do not bend the pipes in an angle more than 90°.

When pipes are repeatedly bent or stretched , the material will

harden, making it dif

fi

cult to bend or stretch them any more. Do

not bend or stretch the pipes more than three times.

(1) Remove the control box cover and install each connection

wire.

Control box cover

Screw

(2) After wiring is complete, secure the remote controller cord,

connection cord, and power cord with the cord clamps.

Connection cord

(to outdoor unit)

Cord clamp

Remote

controller cord

Cord clamp

45 mm

7

5

3

INSTALLING THE

COUPLER HEAT

INSULATION

Body

Be sure to overlap the

insulation

Coupler heat insulation

No gap

Coupler heat

insulation

After checking for gas leaks, insulate by wrapping insulation

around the two parts (gas and liquid) of the indoor unit coupling,

using the coupler heat insulation.

After installing the coupler heat insulation, wrap both ends with

vinyl tape so that there is no gap.

3. CONNECTION OF WIRING

2. CONNECTION CORD PREPARATION

Keep the earth wire longer than the other wires.

Power supply cord

or connection cord

20

mm

50

mm

or

m

or

e

Earth wire

TEST RUN

6

STATIC PRESSURE

CHARACTERISTIC

2. AIR FLOW SETTING

The air

fl

ow is set according to the DIP switch settings in the

following tables.

1. FLARING

(1) Cut the connection pipe to the necessary length with a pipe

cutter.

(2) Hold the pipe downward so that cuttings will not enter the pipe

and remove the burrs.

(3) Insert the

fl

are nut (always use the

fl

are nut attached to the

indoor and outdoor units respectively) onto the pipe and

perform the

fl

are processing with a

fl

are tool.

Use the special R410A

fl

are tool, or the conventional

fl

are

tool.

Check if [L] is flared uniformly

and is not cracked or scratched

L

Die

A

Pipe

B

CAUTION

1

Be sure to apply the pipe against the port on the

indoor unit correctly. If the centering is improper,

the

fl

are nut cannot be tightened smoothly. If

the

fl

are nut is forced to turn, the threads will

be damaged.

2

Do not remove the

fl

are nut from the indoor unit

pipe until immediately before connecting the

connection pipe.

(2) Centering the pipe against port on the indoor unit, turn the

fl

are nut with your hand.

To prevent gas leakage, coat the flare

surface with alkylbenzene oil (HAB).

Do not use mineral oil.

When the

fl

are nut is tightened properly by your hand, use a torque

wrench to

fi

nally tighten it.

Holding

spanner

Torque wrench

Unit

side

CAUTION

Hold the torque wrench at its grip, keeping it in the

right angle with the pipe , in order to tighten the

fl

are nut correctly.

Flare nut

Tightening torque

6.35 mm (1/4 in.) dia.

14 to 18 N·m (140 to 180 kgf·cm)

15.88 mm (5/8 in.) dia.

63 to 77 N·m (630 to 770 kgf·cm)

CAUTION

Be sure to connect the gas pipe after connecting

the liquid pipe completely.

CAUTION

Must

fi

t tightly against body without any gap.

HOW TO CONNECT WIRING TO THE

TERMINALS

A. For solid core wiring

(1) Cut the wire end with a wire cutter or wire-cutting pliers,

then strip the insulation to about 25 mm (15/16”) to expose

the solid wire.

(2) Using a screwdriver, remove the terminal screw(s) on the

terminal board.

(3) Using pliers, bend the solid wire to form a loop suitable for

the terminal screw.

(4) Shape the loop wire properly, place it on the terminal

board and tighten securely with the terminal screw using

a screwdriver.

B. For strand wiring

(1) Cut the wire end with a wire cutter or wire-cutting pliers,

then strip the insulation to about 10 mm (3/8”) to expose

the strand wiring.

(2) Using a screwdriver, remove the terminal screw(s) on the

terminal board.

(3) Using a round terminal fastener or pliers, securely clamp

a round terminal to each stripped wire end.

(4) Position the round terminal wire, and replace and tighten

the terminal screw using a screwdriver.

WARNING

1

Before starting work, check that power is not

being supplied to the indoor unit and outdoor

unit.

2

Match the terminal board numbers and con-

nection cord colors with those of the outdoor

unit.

Erroneous wiring may cause burning of the

electric parts.

3

Connect the connection cords firmly to the

terminal board. Imperfect installation may

cause a

fi

re.

4

Always fasten the outside covering of the

connection cord with the cord clamp. (If the

insulator is chafed, electric leakage may occur.)

5

Always connect the ground wire.

6

Install the remote controller wires so as not to

be direct touched with your hand.

(3) Install control box cover.

Adjust the position of the screws for control box cover according

to the installation.

Pipe outside

diameter

Width across

fl

ats

of Flare nut

6.35 mm (1/4 in.)

17 mm

9.52 mm (3/8 in.)

22 mm

12.70 mm (1/2 in.)

26 mm

15.88 mm (5/8 in.)

29 mm

Pipe outside diameter

Dimension A (mm)

Flare tool for R410A, clutch type

6.35 mm (1/4 in.)

0 to 0.5

9.52 mm (3/8 in.)

12.70 mm (1/2 in.)

15.88 mm (5/8 in.)

Width across flats

When using conventional

fl

are tools to

fl

are R410A pipes, the

dimension A should be approximately 0.5 mm more than

indicated in the table (for

fl

aring with R410A

fl

are tools) to achieve

the speci

fi

ed

fl

aring. Use a thickness gauge to measure the

dimension A.

Pipe outside diameter

Dimension B (mm)

6.35 mm (1/4 in.)

9.1

9.52 mm (3/8 in.)

13.2

12.70 mm (1/2 in.)

16.6

15.88 mm (5/8 in.)

24.0

0

-0.4

CAUTION

1

Tighten the indoor unit connection cord (to the

outdoor unit) and power supply indoor and

outdoor unit terminal board connections

fi

rmly

with the terminal board screws. Faulty connec-

tion may cause a

fi

re.

2

If the indoor unit connection cord (to the outdoor

unit) and power supply are wired incorrectly, the

air conditioner may be damaged.

3

Wire the indoor unit connection cord (to the

outdoor unit) by matching the numbers of

the outdoor and indoor units terminal board

numbers as shown in terminal label.

4

Ground both the indoor and outdoor units by

attaching a ground wire.

5

Unit shall be grounded in compliance with the

applicable local and national codes.

RECOMMENDED RANGE OF

EXTERNAL STATIC PRESSURE

30Pa to 150Pa

Mode

Setting condition

Static pressure range

1

Normal

30

g

P

g

40

2

High static pressure 1

56

g

P

g

65

3

High static pressure 2

95

g

P

g

105

4

High static pressure 3

142

g

P

g

150

CAUTION

If the applicable static pressure does not match the

static pressure mode, the static pressure mode may

be changed to another mode automatically.

1. FAN PERFORMANCE AND AIR FLOW

EXTERNAL STATIC PRESSURE

CHECK ITEMS

(1) Is operation of each button on the remote control unit nor-

mal?

(2) Does each lamp light normally?

(3) Do not air

fl

ow direction louvers operate normally?

(4) Is the drain normal?

(5) Is there any abnormal noise and vibration during operation?

• Do not operate the air conditioner in the running state for a

long time.

• To end test operation, press the remote control unit START/

STOP button.

(When the air conditioner is run by pressing the test run button,

the OPERATION indicator lamp and TIMER indicator lamp will

simultaneously

fl

ash slowly.)

[Using the wired remote control]

• For the operation method, refer to the operating manual.

(1) Stop the air conditioner operation.

(2) Press the master control button and the fan control button

simultaneously for 2 seconds or more to start the test run.

Test run display

FAN

MODE

(3) Press the start/stop button to stop the test run.

[Troubleshooting at the remote control LCD]

This is possible only on the wired remote control.

[SELF-DIAGNOSIS]

If an error occurs, the following display will be shown.

(“EE” will appear in the set room temperature display.)

SU MO TU WE TH FR SA

Unit number

Error code

EX. Self-diagnosis

Error code

Error contents

01

13

26

27

Indoor signal error

00

Wired remote controller abnormal

02

Indoor room temperature sensor error

04

Indoor heat exchanger temperature sensor

(middle) error

28

Indoor heat exchanger temperature sensor

(inlet) error

09

Float switch operated

0C

Outdoor discharge pipe temperature sensor

error

06

Outdoor heat exchanger temperature sensor

(outlet) error

0A

Outdoor temperature sensor error

15

Compressor temperature sensor error

1d

2-way valve temperature sensor error

1E

3-way valve temperature sensor error

29

Outdoor heat exchanger temperature sensor

(middle) error

20

Indoor manual auto switch abnormal

2A

Power supply frequency detection error

17

IPM protection

18

CT error

1A

Compressor location error

1b

Outdoor fan error

1F

Connected indoor unit abnormal

1c

Outdoor unit computer communication error

12

Indoor fan abnormal

0F

Discharge temperature error

24

Exessive high pressure protection on cooling

2c

4-way valve abnormal

16

Pressure switch abnormal

2b

Compressor temperature error

19

Active

fi

lter abnormal

25

PFC circuit error

[Using the wireless remote control]

• For the operation method, refer to the operating manual.

• The outdoor unit may not operate depending on the room

temperature. In this case, press the test run button on the

remote control unit while the air conditioner is running. (Point

the transmitter section of the remote control unit toward the

air conditioner and press the test run button with the tip of a

ball-point pen, etc.)

If “CO” appears in the unit number display, there is a remote

controller error. Refer to the installation instruction sheet included

with the remote controller.

SPECIAL INSTALLATION

METHODS

8

CAUTION

1

When setting DIP switches, do not touch any

other parts on the circuit board directly with

your bare hands.

2

Be sure to turn off the main power.

GROUP CONTROL SYSTEM

A number of indoor units can be operated at the same time using

a single remote controller.

(1) Wiring method (indoor unit to remote controller)

1 2 3

1 2 3

1 2 3

1 2 3

1 2 3

Indoor unit

No.

0

Indoor unit

No.

1

Indoor unit

No.

2

Indoor unit

No.

3

Remote controller wire

Remote

controller

(2) DIP switch setting (Indoor unit)

Set the unit number of each indoor unit using DIP switch on the

indoor unit circuit board. (See following table and

fi

gure.)

DIP switch is normally set to make unit number No. 0.

Indoor unit

Unit number

DIP SWITCH No.

1

2

3

4

0

OFF

OFF

OFF

OFF

1

ON

OFF

OFF

OFF

2

OFF

ON

OFF

OFF

3

ON

ON

OFF

OFF

4

OFF

OFF

ON

OFF

5

ON

OFF

ON

OFF

6

OFF

ON

ON

OFF

7

ON

ON

ON

OFF

8

OFF

OFF

OFF

ON

9

ON

OFF

OFF

ON

10

OFF

ON

OFF

ON

11

ON

ON

OFF

ON

12

OFF

OFF

ON

ON

13

ON

OFF

ON

ON

14

OFF

ON

ON

ON

15

ON

ON

ON

ON

Example : No. 3

ON

1

2

3

4

CUSTOMER GUIDANCE

9

Explain the following to the customer in accordance with the

operating manual:

(1) Starting and stopping method, operation switching, tempera-

ture adjustment, timer, air

fl

ow switching, and other remote

control unit operations.

(2) Air filter removal and cleaning, and how to use the air

louvers.

(3) Give the operating and installation manuals to the customer.

(4) If the signal code is changed, explain to the customer how it

changed (the system returns to signal code A when the bat-

teries in the remote control unit are replaced).

*(4) is applicable to using wireless remote control.

FUNCTION SETTING

Setting

Setting Value

Static pressure

Cooler room temperature

correction

Heater room temperature

correction

Auto restart

Indoor room temperature sensor

switching function

• Follow the instructions in the Local Setup Procedure, which is

supplied with the remote control, in accordance with the installed

condition. After the power is turned on, perform the Function

Setting on the remote control.

• The settings may be selected between the following two: Func-

tion Number or Setting Value.

• Settings will not be changed if invalid numbers or setting values

are selected.

Setting the Static Pressure

Determine the wind volume in each mode i.e., applicable

range of static pressure, refering to [7] STATIC PRESSURE

CHARACTERISTICS. (The unit is factory-set to “00”)

Setting the Cooler Room Temperature Correction

• Depending on the installed environment, the room temperature

sensor may require a correction. The settings may be selected

as shown in the table below. (The unit is factory-set to “00”.)

Setting the Heater Room Temperature Correction

• Depending on the installed environment, the room temperature

sensor may require a correction. The settings may be changed

as shown in the table below. (The unit is factory-set to “00”.)

Setting Other Functions

• The following settings are also possible, depending on the

operating conditions. (The unit is factory-set to “00”.)

Auto Restart

Indoor Room Temperature Sensor Switching Function (Wired

remote controller only)

• If setting value is “00”, room temperature is controlled by the

indoor unit temperature sensor.

• If setting value is “01”, room temperature is controlled by either

indoor unit temperature sensor or remote control unit sensor.

[When using the wireless remote controller]

SWITCHING REMOTE CONTROL UNIT

SIGNAL CODES

• Con

fi

rm the setting of the remote control unit signal code and

the printed circuit board setting.

If these are not con

fi

rmed, the remote control unit cannot be

used to operate for the air conditioner.

Setting Record

• Record any changes to the settings in the following table.

Jumper wire

Remote control unit

signal code

JM1

JM2

Connect

Connect

A (Primary setting)

Disconnect

Connect

b

Connect

Disconnect

c

Disconnect

Disconnect

d

Setting Description

Function Number

Setting Value

Yes

40

00

No

01

Setting Description

Function Number

Setting Value

Standard

31

00

Lower control

01

Slightly warmer control

02

Warmer control

03

Setting Description

Function Number

Setting Value

Standard

30

00

Lower control

01

Setting Description

Function Number

Setting Value

Normal

21

00

High static pressure 1

01

High static pressure 2

02

High static pressure 3

03

Setting Description

Function Number

Setting Value

No

42

00

Yes

01

After completing the FUNCTION SETTING, be sure to turn off

the power and turn it on again.

9374318148_B2back.indd 1

9374318148_B2back.indd 1

8/23/06 4:43:04 PM

8/23/06 4:43:04 PM

Содержание AO*A12LACL series

Страница 4: ...1 SPECIFICATIONS R410A DUCT type INVERTER ...

Страница 12: ...2 DIMENSIONS R410A DUCT type INVERTER ...

Страница 17: ...3 REFRIGERANT SYSTEM DIAGRAM R410A DUCT type INVERTER ...

Страница 22: ...4 CIRCUIT DIAGRAM R410A DUCT type INVERTER ...

Страница 23: ...04 01 4 CIRCUIT DIAGRAM MODEL AR A12 14 18LATN ...

Страница 24: ...04 02 MODEL AR A24 36 45LATN COIL ...

Страница 25: ...04 03 MODEL AO A12 14 18 24LACL ...

Страница 26: ...04 04 MODEL AO A36 45LATL ...

Страница 27: ...5 DESCRIPTION OF EACH CONTROL OPERATION R410A DUCT type INVERTER ...

Страница 50: ...6 REFRIGERANT CAUTION R410A R410A INVERTER DUCT type ...

Страница 59: ...7 TROUBLE SHOOTING R410A DUCT type INVERTER ...

Страница 98: ...8 APPENDING DATA R410A INVERTER DUCT type ...

Страница 114: ...9 INSTALLATION MANUAL R410A DUCT type INVERTER ...

Страница 133: ...1116 Suenaga Takatsu ku Kawasaki 213 8502 Japan June 2007 Printed in Japan ...