Page | 3

Installation Introduction

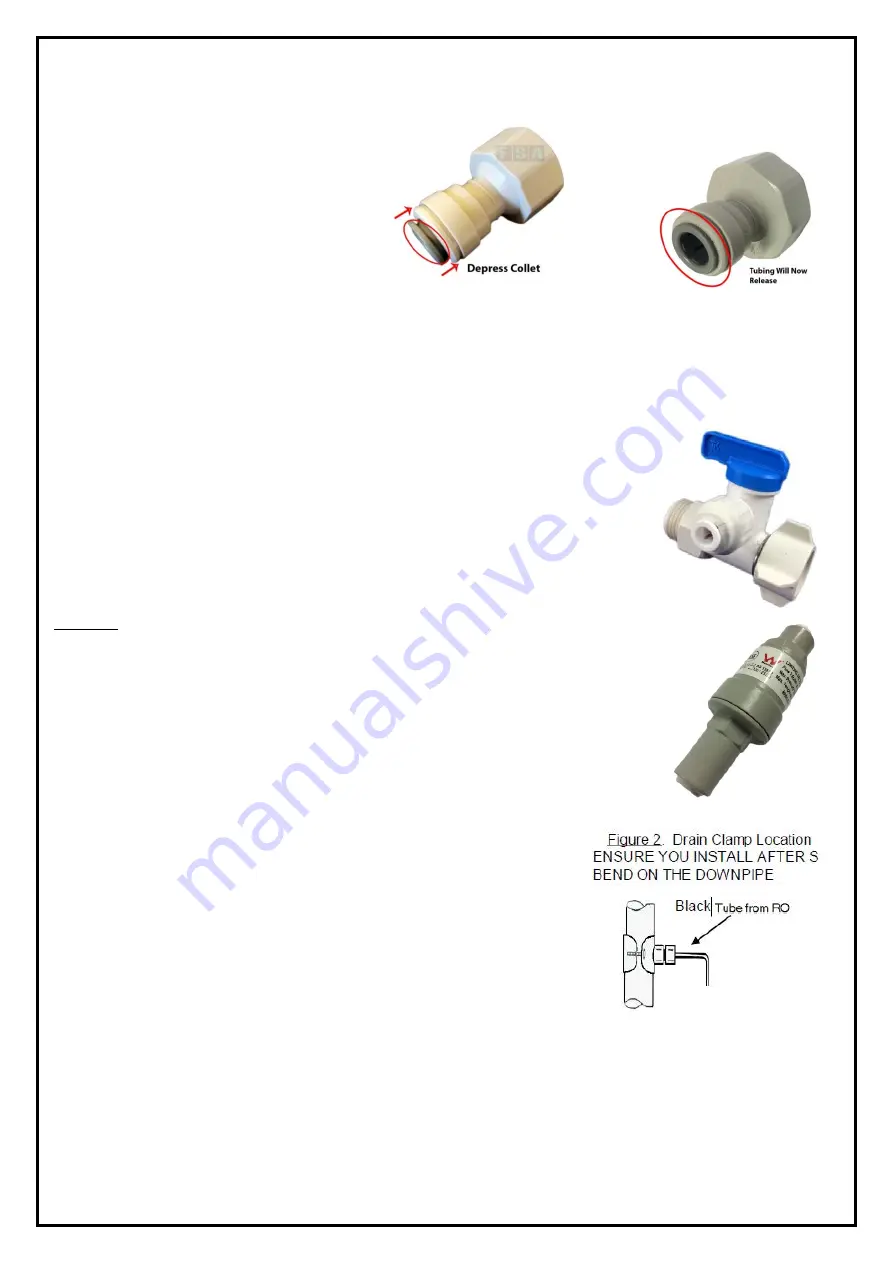

I. Working with Quick Connect Fittings

If you come across a push-fit fitting, you

need to firmly push the tubing into the

opening until you feel a “click” which

signifies that the tubing has pushed

through the internal O-ring and is seated

correctly. If leaking occurs, it may be due

to roughly cut tubing OR the tubing is not

pushed in far enough. To remove tubing

from push-fit fittings, depress the floating

collet (shown to the right), then pull the tubing out.

II. Flushing

Laws and regulations prevent us from wet-testing these filtration systems prior to sending them out.

Therefore, during assembly of these systems they are not pressure tested so it is possible to have a small

leak in a connection (which is simply fixed by re-seating the tubing or tightening a fitting). As the filters are

dry packed, the systems will require flushing before first use.

Installing Connections

I. Feed Water Connection

Using the supplied Feed Water Adaptor [FWA] (Pictured right), Locate the

connection between the kitchen tap & cold-water line (Usually a flex line). Shut

off the incoming water and bleed pressure from the line by opening the tap.

Disconnect the flex line from the cold-water inlet and install the Feed Water

Adaptor in between.

DO NOT apply thread tape to these connections as they are designed to use the

washers only – Thread tape is only required on the male thread of the FWA if it is

not installing to a flex line.

With the blue handle facing in line with the cold-water line (As pictured) the valve is

in the off position. During this point, you can turn the water back on to check for

leaks in the valve installation.

A pressure limiting valve must be fitted between the FWA and the Filter System to

limit the incoming pressure to a maximum of 500 kPa (70 PSI). Failure to install a

PLV may void warranty.

II. Drain Clamp

The best installation point for the drain clamp is below the S bend

(Trap). The Vertical tailpiece is ideal.

1. Mark the position of the hole on the pipe and drill through using

a ¼” (6mm) drill bit (One side only).

2. Unscrew the clamp and wrap it around the pipe, loosely screw

it back up leaving enough slack so you can position the hole

with the outlet of the clamp.

3. Tighten the clamp to create a seal.

III. Drilling Faucet Hole - Stainless Steel Sink)

1. Drilling through a stainless-steel sink can be achieved by marking the location with a centre punch

and drilling a 3/16” Pilot Hole – When drilling through stainless steel – lower speeds are better with

a sharper bit to avoid burning the surface of the sink.

2. Using a 1/2” or 7/16” carbide or sharp drill bit, enlarge the hole to fit the stem of the faucet (7/16”

Thread)

Содержание GT1-26-5

Страница 14: ......