17 - ENGLISH

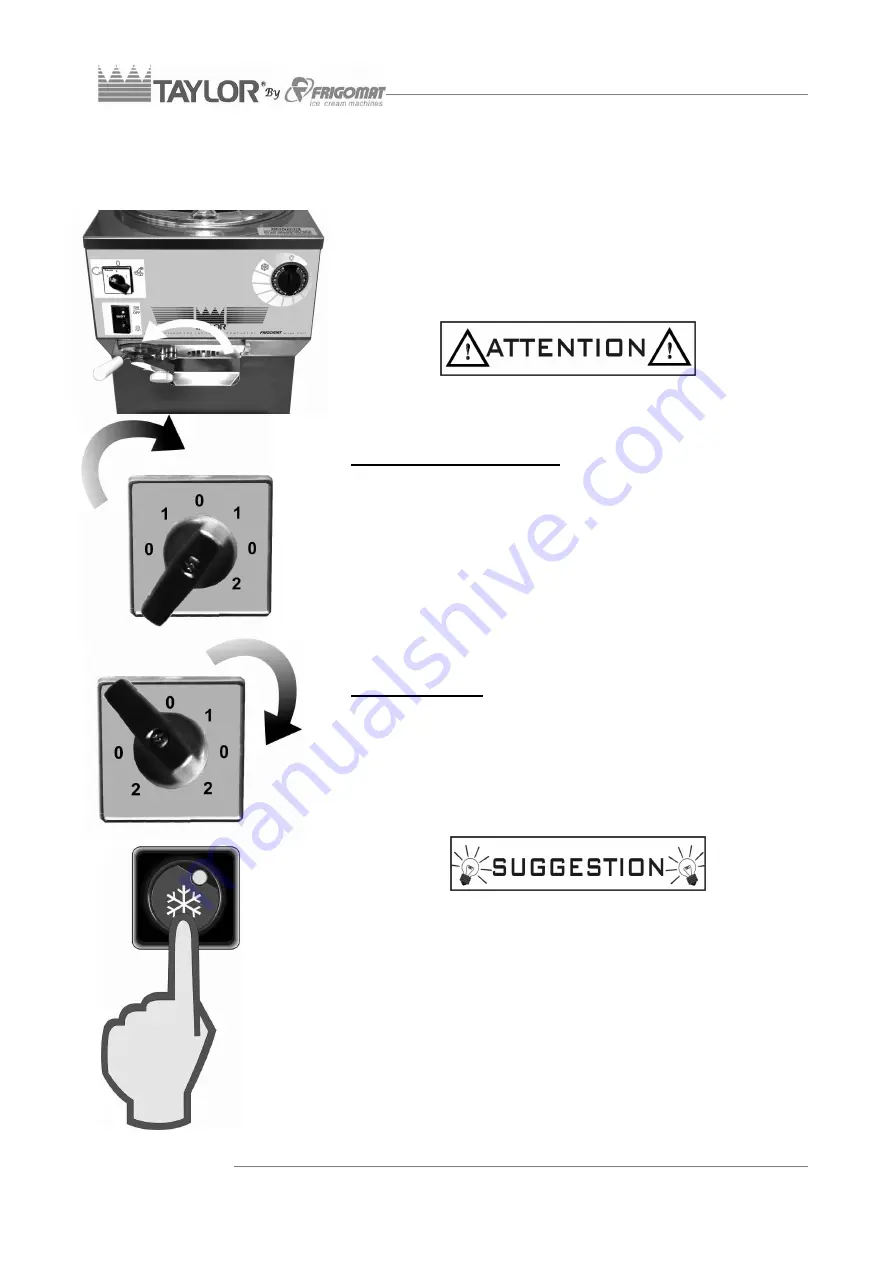

6.4 EXTRACTION

To extract the product at the end of a productive cycle,

refer to the following instructions:

- Position a cold and clean tub of adequate capacity on the

front shelf of the machine.

- Check that the production cycle has ended and the timer

is at position 0 for at least 30”.

This simple action can prolong the life span of the

scrapers and safeguard the beater motor.

MODELS C154- C153

- Pull the dispensing lever up to open the dispensing

plate

- Rotate the selector clockwise on Pos.1 to release the

low speed extraction.

- Rotate the selector clockwise on Pos.2 to release the

high speed extraction. The compressor is OFF.

- After the extraction, rotate the selector onto 0, open the

lid and remove the eventual product residues with a

plastic spatula.

MODEL C151

- Pull the dispensing lever up to open the dispensing

plate

- Rotate the selector clockwise on Pos.1 to release the

low speed extraction.

Rotate the selector clockwise on Pos.2 to release the

high speed extraction. The compressor is OFF

During the extraction phase, by pushing the “continuous

cod” button, it is possible to keep the compressor running

in order to preserve the product at the correct

consistency. However, the compressor must be switched

off by acting on the timer, when about half of the product

has already been extracted.

- When extraction has been completed, turn the selector

switch to 0, open the lid and extract any residual product

using a plastic spatula.

Содержание TAYLOR C151

Страница 27: ...APPENDICI 2 C154 C153 C151 ...

Страница 31: ...APPENDICI 6 ...

Страница 32: ...VII C154 C153 s02 Tav 1 ...

Страница 34: ...IX APPENDICI C151 s02 Tav 2 ...

Страница 36: ...XI APPENDICI C154 A s02 Tav 3 ...

Страница 38: ...XIII C153 A s02 Tav 4 ...

Страница 40: ...XV C153 W s02 Tav 5 ...

Страница 42: ...XVII C151 A s02 Tav 6 ...

Страница 44: ...XIX C151 W s02 Tav 7 ...

Страница 46: ...XXI C154 C153 s02 Tav 8 ...

Страница 48: ...XXIII C151 s02 Tav 9 ...

Страница 50: ...XXV C154 s02 Tav 10 ...

Страница 52: ...XXVII C153 s02 Tav 11 ...

Страница 54: ...XXIX C151 s02 Tav 12 ...

Страница 56: ...XXXI C154 C153 C151 s02 Tav 13 ...

Страница 58: ...XXXIII C154 C153 s02 Tav 14 ...

Страница 60: ...XXXV C151 s02 Tav 15 ...

Страница 62: ...NOTE NOTES NOTES BEMERKUNG NOTA ...

Страница 63: ......