47

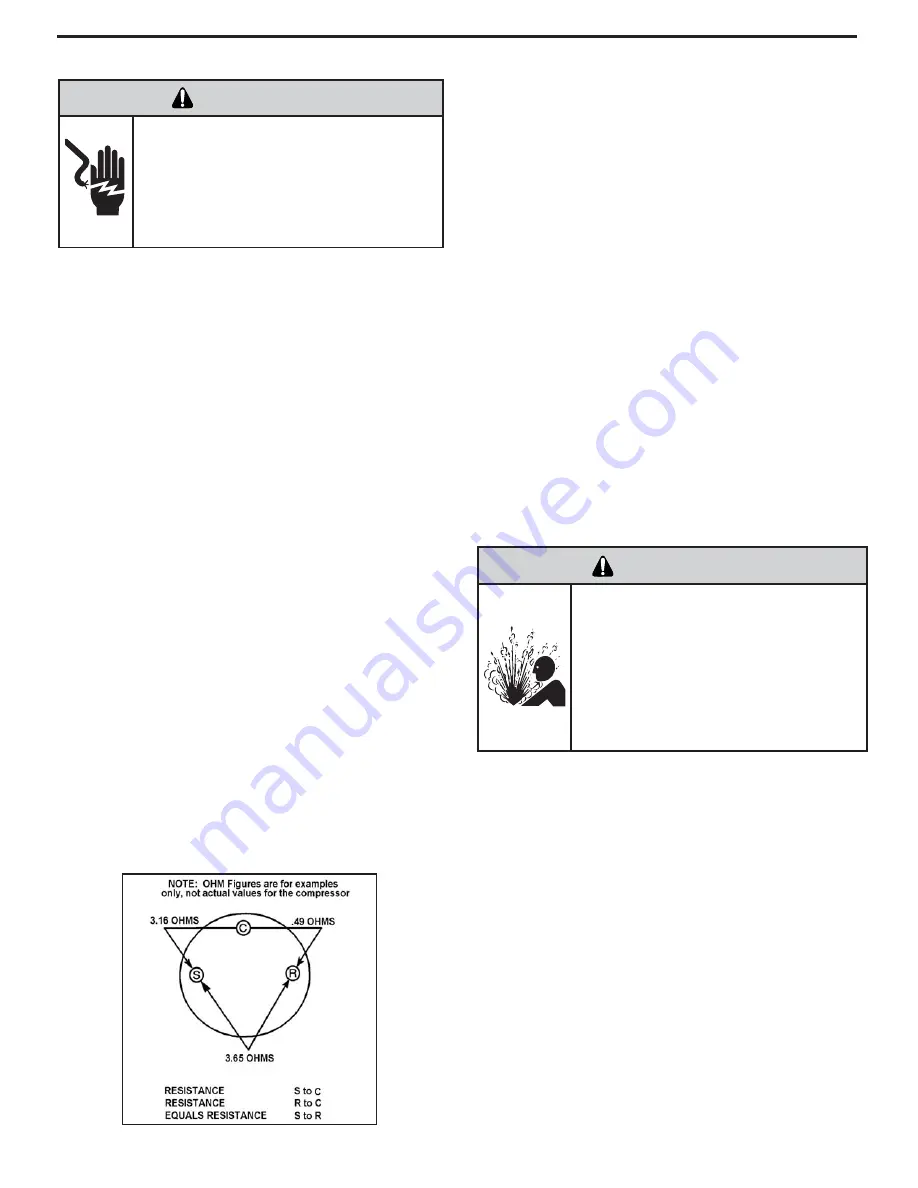

Single Phase Resistance Test

t

e

s

d

n

a

s

l

a

n

i

m

r

e

t

r

o

s

s

e

r

p

m

o

c

e

h

t

m

o

r

f

s

d

a

e

l

e

h

t

e

v

o

m

e

R

the ohmmeter on the lowest scale (R x 1).

n

o

m

m

o

c

s

l

a

n

i

m

r

e

t

m

o

r

f

r

e

t

e

m

m

h

o

e

h

t

f

o

s

d

a

e

l

e

h

t

h

c

u

o

T

r

e

t

e

m

m

h

o

e

h

t

f

o

s

d

a

e

l

e

h

t

h

c

u

o

t

,t

x

e

N

.

)

”

S

“

o

t

”

C

“

(

t

r

a

t

s

o

t

from terminals common to run (“C” to “R”).

Add values “C” to “S” and “C” to “R” together and

.

)

”

R

“

o

t

”

S

“

(

s

l

a

n

i

m

r

e

t

n

u

r

o

t

t

r

a

t

s

m

o

r

f

e

c

n

a

t

s

i

s

e

r

k

c

e

h

c

Resistance “S” to “R” should equal the total of “C” to “S”

and “C” to “R.”

In a single phase PSC compressor motor, the highest

o

t

”

S

“

(

s

n

o

it

c

e

n

n

o

c

n

u

r

e

h

t

o

t

t

r

a

t

s

e

h

t

m

o

r

f

e

b

l

li

w

e

u

l

a

v

e

h

t

o

t

t

r

a

t

s

e

h

t

m

o

r

f

s

i

e

c

n

a

t

s

i

s

e

r

t

s

e

h

g

i

h

t

x

e

n

e

h

T

.

)

”

R

“

common connections (“S” to “C”). The lowest resistance

is from the run to common. (“C” to “R”) Before replacing a

compressor, check to be sure it is defective.

GROUND TEST

Use an ohmmeter set on its highest scale. Touch one

lead to the compressor body (clean point of contact as

a good connection is a must) and the other probe in turn

to each compressor terminal. If a reading is obtained the

compressor is grounded and must be replaced.

Check the complete electrical system to the compressor

and compressor internal electrical system, check to be

certain that compressor is not out on internal overload.

Complete evaluation of the system must be made

whenever you suspect the compressor is defective. If

the compressor has been operating for sometime, a

careful

examination must be made to determine why the

compressor failed.

Many compressor failures are caused by the following

conditions:

1. Improper air

fl

ow over the evaporator.

2. Overcharged refrigerant system causing liquid to be

returned to the compressor.

3. Restricted refrigerant system.

4. Lack of lubrication.

5. Liquid refrigerant returning to compressor causing oil

to be washed out of bearings.

6. Noncondensables such as air and moisture in

the system. Moisture is extremely destructive to a

refrigerant system.

7. Capacitor (see page 34).

CHECKING COMPRESSOR EFFICIENCY

The reason for compressor inef

fi

ciency is normally due

to broken or damaged suction and/or discharge valves,

reducing the ability of the compressor to pump refrigerant

gas.

This condition can be checked as follows:

1. Install a piercing valve on the suction and discharge or

liquid process tube.

2. Attach gauges to the high and low sides of the system.

3. Start the system and run a “cooling or heating perfor

-

mance test.” If test shows:

A.

Below

normal high side pressure

B.

Above

normal low side pressure

C.

Low

temperature difference across coil

The compressor valves are faulty - replace the

compressor.

ELECTRIC SHOCK HAZARD

WARNING

Turn off electric power before service or

installation. Extreme care must be used, if it

becomes necessary to work on equipment

with power applied.

Failure to do so could result in serious injury or

death.

Sealed Refrigeration System contains refrigerant

and oil under high pressure.

Proper safety procedures must be followed,

and proper protective clothing must be worn

when working with refrigerants.

Failure to follow these procedures could

result in serious injury or death.

WARNING

HIGH PRESSURE HAZARD