5

Main Menu

1

4

7

2

0

5

8

Enter

Del

9

3

6

BACK

Press “Enter”

Step 2

Input “

461

”

on keypad

Clear Errors

Main Menu Options

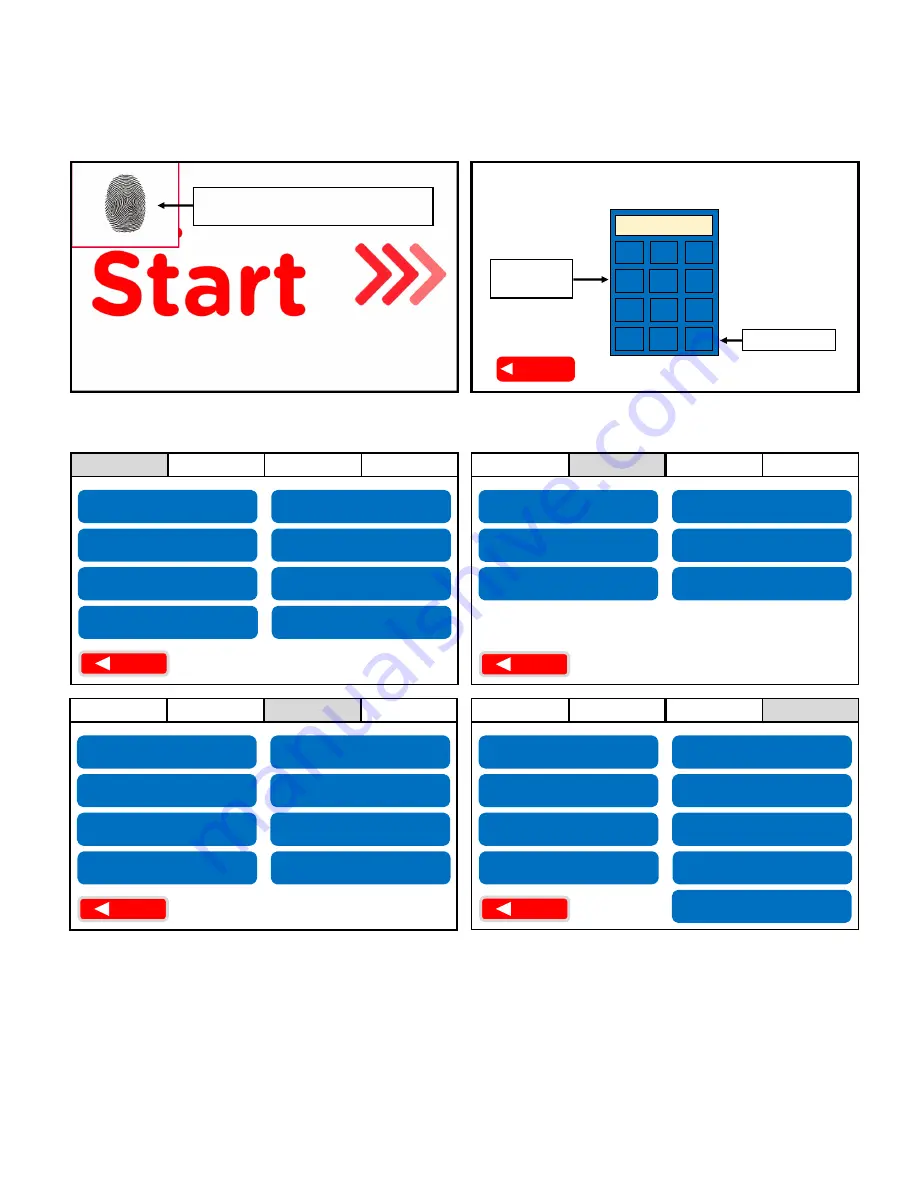

The Main Menu utilizes a 4

-

tab layout that results in a single access point.

Press and hold the top left corner

for 10 seconds until a keypad appears

Step 1

Access the Main Menu

Locate the lower screen and follow the instructions below to access the

Main Menu

:

Network

Used while Troubleshooting errors from pages 6

-

13

1.

Follow Steps 1 & 2 in the “Access the Main Menu” above.

2.

Press the “Clear Errors” button on the “General” tab.

General

Service

Procedures

BACK

Network

General

Service

Procedures

Network

General

Service

Procedures

BACK

Network

General

Service

Procedures

BACK

Blender Info

Sanitize Time

Sanitize Description

LVCB Status Window

*

Reset Screen

Cleaning and Sanitizing Log

Contact f’real

Check Cell Signal

Synchronize with Server

Configure Network for

Cellular Connection

Network Status

Restart Network

Configure Network for

Ethernet

Raise Cupholder

Shut Down the Blender

Calibrate Cupholder

Water Purge/Boil Water

Set Time Zone

Reset Blender

Configure Languages

Activate Cleaning

and Sanitizing

Toggle Registration

Update Content

f’real Training

Gather Diagnostic Info

Set Volume

Manual Commands

Update Firmware

from HEX File

Reinstate Customer

Install Sequence

Run Diagnostic Routine

*

How to Reset a Blender Error Code

BACK

Содержание FRLB6

Страница 1: ...1 Rev D Model FRLB6 Service Manual...

Страница 2: ...2...