milled slot to suit your

servo. Shown installed

here is a digital

JR3401 servo.

Centre the servo with

your Tx, set the travels

to maximum, and fix a

short servo arm onto it

at 90° to the servo

case as shown. Screw

the servo into place,

with the output shaft

towards the leading

edge of the Fin.

Route the extension

cable upward and for-

ward, thru' the milled

hole in the front balsa

spar, and then down

and out of the bottom

of the fin. Apply some

masking tape to the

outside of the fin (left

side) and carefully

mark the position of

the servo arm centre-

line on it. Extend this

line onto the rudder,

exactly perpendicular

to the leading edge.

Drill a Ø 2.2mm hole

right thru the rudder,

on this line, 10mm

from the leading edge

and tap M3 for the

control horn in the same way as for the elevators and ailerons. Screw the M3 threaded rod into

the threaded hole, and secure with a drop of 30 minute epoxy and microballoons through an 8mm

hole drilled in the bottom of the rudder. Make up the linkage as shown, using your choice of hard-

ware (M2 or 2 x 56 UNC). Cut a small slot in the outer skin of the rudder, as shown, and lengthen

the slot until you can fit the linkage as shown and obtain throws of 15mm both sides.

The fin is secured to the fuselage with a M4 x 25 bolt at the front, that screws into an M4 T-nut that

has been fitted into the fin already. The hole has been drilled in the fuselage for the bolt, but can

be adjusted if necessary. Cut a small reinforcing plate of 3mm plywood, 20 x 30mm, and drill a

4mm hole in the centre of it. Wax the M4 bolt thread. Pass the M4 bolt thru’ the hole and screw it

up into the stab from inside the fuselage. Make any small adjustments to the Fin position now, so

that it is straight with the fuselage centreline. Glue the plywood reinforcing plate to the inside of

the fuselage with 30 min. epoxy and micro. Secure the rudder servo extension cable to the side

of the fuselage and make sure that it cannot come into contact with the hot thrust tube.

Fox Composites Co., Ltd.

8

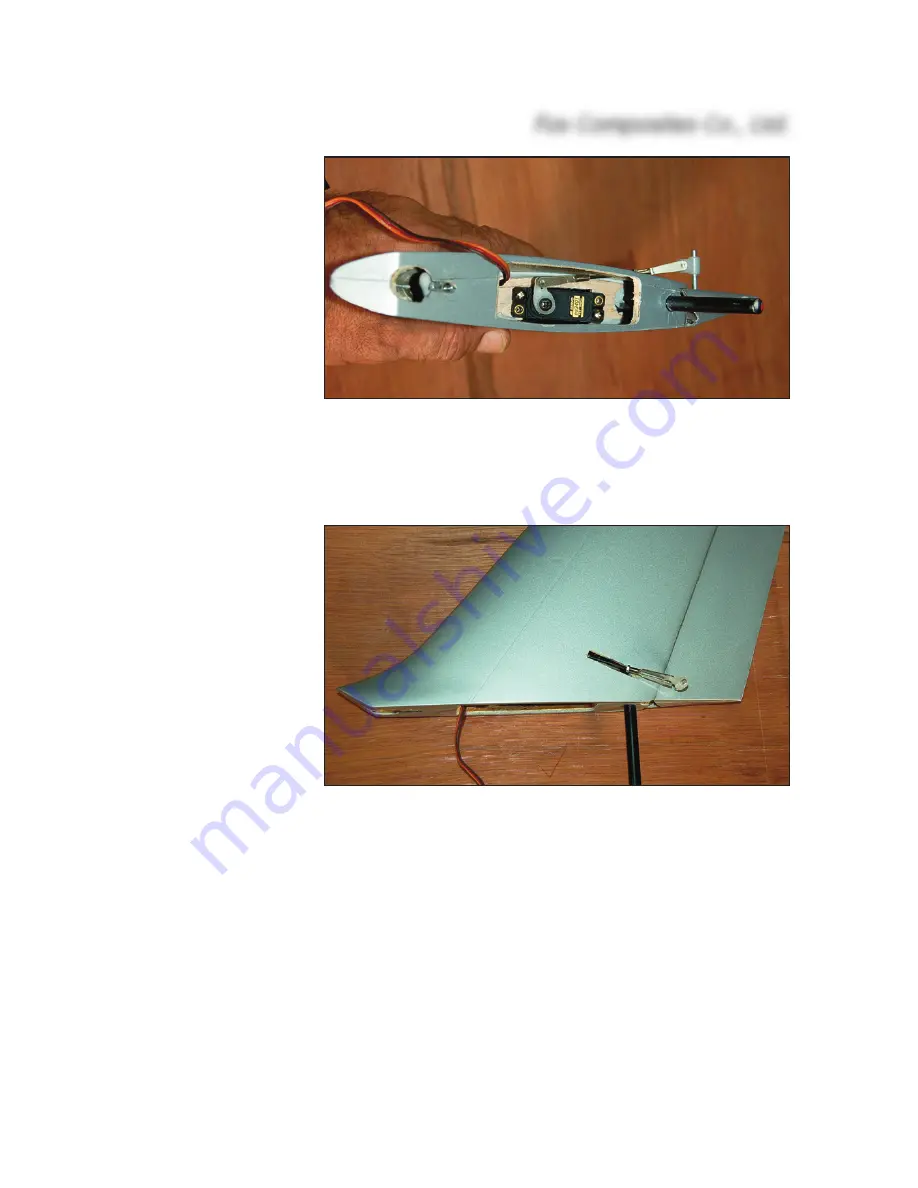

(above) Rudder is controlled by min. 4kg mini-servo servo screwed

to factory-installed plywood mount. Use a short servo arm and adjust

control horn to give 13 - 15mm throw each way.

(below) Fin is secured to the stabiliser with Ø7mm spar rod that fits

into a fibreglass tube, and an M4 bolt at the front into a T-nut in the

base of the fin - all factory-finished for you.