QUESTIONS OR TROUBLE? Contact Forney Industries at 1-800-521-6038

[email protected] • askforney.com • forneyind.com

EN_v1

TROUBLESHOOTING TIPS

• Usually due to low input power.

• Pulse settings may be causing poor fusion. Increase the Pulse (% On) setting or set the

Pulse (Hz) to 2 Hz or higher.

• Welder should be only thing plugged into circuit.

• Avoid using extension cords. If one must be used, it must be #12 AWG (120V) or

#10 AWG (240V) or larger; 25’ (8m) or shorter.

• Generators must be 10,500 W (240 V) or 4,000 W (120 V) continuous output and

not have a low-idle function (or have it disabled).

Low weld output or poor fusion

Frequently tripping circuit breaker or exceeding

duty cycle

Connect ground clamp to clean, bare metal. No rust,

paint or other coatings. Attach the ground clamp

directly to the workpiece if you are experiencing

issues.

Workpiece grounding

• Not recommended for this machine.

• Output is DC only which is not suitible for TIG welding

aluminum.

Aluminum welding

DC

ONLY

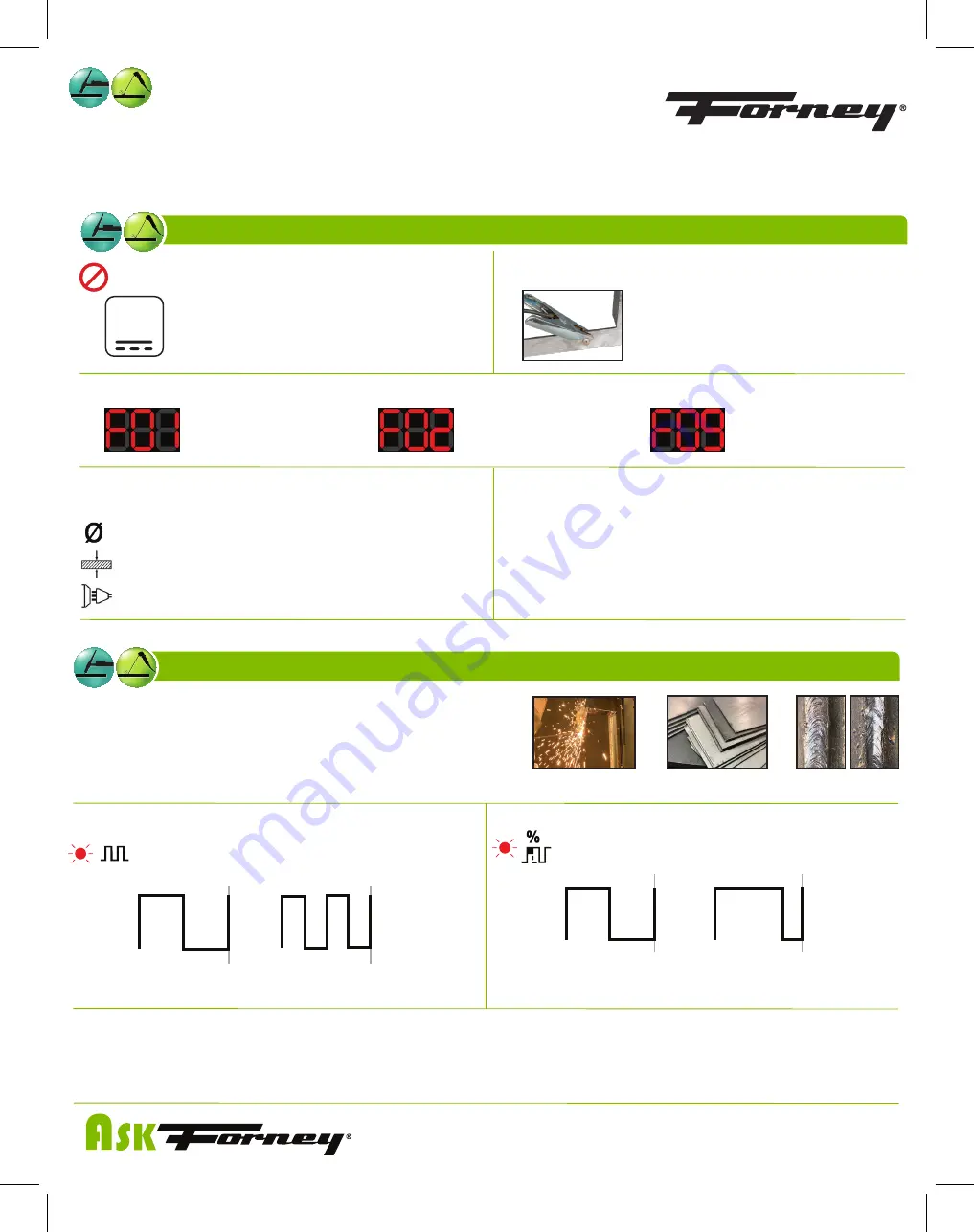

Fault Codes

Duty-cycle exceeded or

insufficient air flow. Allow

machine to cool. Ensure vents

are clear of obstacles. See

manual.

Incorrect input power. Verify

machine is plugged into an

appropriate power source. Use

proper extension cords. See

manual.

Electrode is shorted or stuck to

workpiece. Separate the

electrode or tungsten from the

workpiece and fault will clear.

See manual.

Use 5/32” diameter electrodes or smaller. Some 5/32” will draw too much

amperage (stick).

Trying to weld single pass on material larger than 3/8” thick is not possible with

this machine. Multi-pass recommended for thicker materials.

Welding machine should be the only thing plugged into the circuit.

PULSE WELDING TIPS

• A higher frequency creates a focused puddle and a tight ripple bead pattern. A lower frequency creates a broader puddle and unique ripple bead pattern.

• A higher setting for Pulse (% On) will increase penetration while a lower value is better for thin material.

• Keep Hz over 2 and % On over 40 when stick welding to avoid arc loss and sticking.

• Read the manual for more information.

Expert-Tech Tips:

Why Pulse Weld?

Out of Position

Thin Material

Visually Appealing

How to set up Pulse Welding:

Set pulse frequency from 0.1 up to 10 Hz

changes how fast the arc pulses

Set pulse % On from 10 to 90. Changes

what percent of the pulse is at the user set

output amperage

TROUBLESHOOTING TIPS

180 ST+ WELDER

(NOT RECOMMENDED FOR ALUMINUM)

ITEM# 321

Down to 16 gauge

Pulse welding alternates between the set output amperage and a

reduced amperage. This allows the weld puddle to cool and solidify

during each low amp cycle. This has many benefits such as:

PULSE (Hz)

PULSE (% On)

1 sec

1 sec

1 sec

1 sec

Pulse (Hz) = 1

Pulse (Hz) = 2

Pulse (Hz) = 1

Pulse (% On) = 50

Pulse (Hz) = 1

Pulse (% On) = 75