Installation

Before you begin

§

All dispensers must be installed level in both directions to ensure proper operation.

§

Service and ventilation clearances: 6" (15.3 cm) on right side of dispenser, 6" (15.3 cm) at top for ventilation and

12" (30.5 cm) at top recommended for service.

§

Countertop units installed without legs provide the option of taking utilities out bottom or back of dispenser (on

wall mount units and countertop units with legs, utilities exit from back). See counter cutout drawings for bottom

exiting utilities. For installations where utilities exit through back of dispenser, refer to back view drawings.

§

Counter depth must allow front of sink to be a minimum of 30.00" (76.2 cm) from wall.

Installing countertop dispensers without

legs

1. Position dispenser in desired location, mark

dispenser outline on counter and remove

dispenser.

2. Regardless of whether utilities will exit

through back or bottom of dispenser,

drill four 7/16" holes in counter to anchor

dispenser to counter

(Fig. 1).

3. For utilities exiting through bottom only:

(a) Make cut out

(Fig. 1).

(b) Move drain fitting from back of dispenser and

mount

(Fig. 2).

(c) Cut drain tube to length and attach to barbed

connection.

(d) Move inlet water fitting from back of

dispenser and mount

(Fig. 2).

(e) Cut water tubing to length and re-insert into

water fitting.

4. For all units: Apply a thick bead

approximately 1/4" (7 mm) diameter of

NSF-listed silicone sealant (Dow Corning

RTV-732

®

or equivalent) 1/4" (7 mm) inside

marked outline of dispenser.

5. Carefully lower dispenser on counter in

proper position and secure to counter with

four (4) 3/8"-16UNC bolts.

6. Smooth excess sealant around outside of

dispenser.

Fig. 1

2.00"

(5.1 cm)

12.00"

(30.5 cm)

14.37"

(36.5 cm)

4X

Ø.437"

(11 mm)

hole

1.04"

(2.6 cm)

16.00"

(40.7 cm)

Cutout

connections

through

bottom

12.00"

(30.5 cm)

0.81"

(2.1 cm)

16.00"

(40.7 cm)

1.50"

(3.8 cm)

17.87"

(45.4 cm)

5.62"

(14.3 cm)

Fig. 2 - Bottom exiting utilities (countertop units)

bracket

inlet

fitting

drain

fitting

drain tube

E12CI414A R290, 230 V 50 Hz 5

Содержание Symphony Plus 12 Series

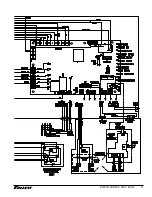

Страница 10: ...Wiring diagram 230 V 50 Hz 10 E12CI414A R290 230 V 50 Hz ...

Страница 11: ...E12CI414A R290 230 V 50 Hz 11 ...

Страница 14: ...14 E12CI414A R290 230 V 50 Hz ...

Страница 15: ...E12CI414A R290 230 V 50 Hz 15 ...