Radio Installation:

39)

The rudder servo and connecting hardware is installed

next. The servo mount is cut to fit a Hitec HS-85 servo.

Simply install the rubber grommets and brass eyelets

supplied with the servo and secure with the screws

included with the servo. The plywood mount is already

pilot drilled for the screws. Install the EZ connector on

the rudder horn making sure the set screw points DOWN.

Bend a 1/4” leg on one end of the 1/16” wire rudder

pushrod. Insert the bent end into the outer hole of the

rudder servo arm and secure with the Du-Bro nylon

keeper. Insert the other end of the rudder pushrod through

the EZ connector on the rudder horn. With the servo

centered at neutral and the rudder also secured in the

neutral position, drill holes for the rudder horn making sure the center line of the EZ connector is directly over

the rudder hinge line. Secure the rudder horn to the rudder. Travel adjustments will be covered in a later step.

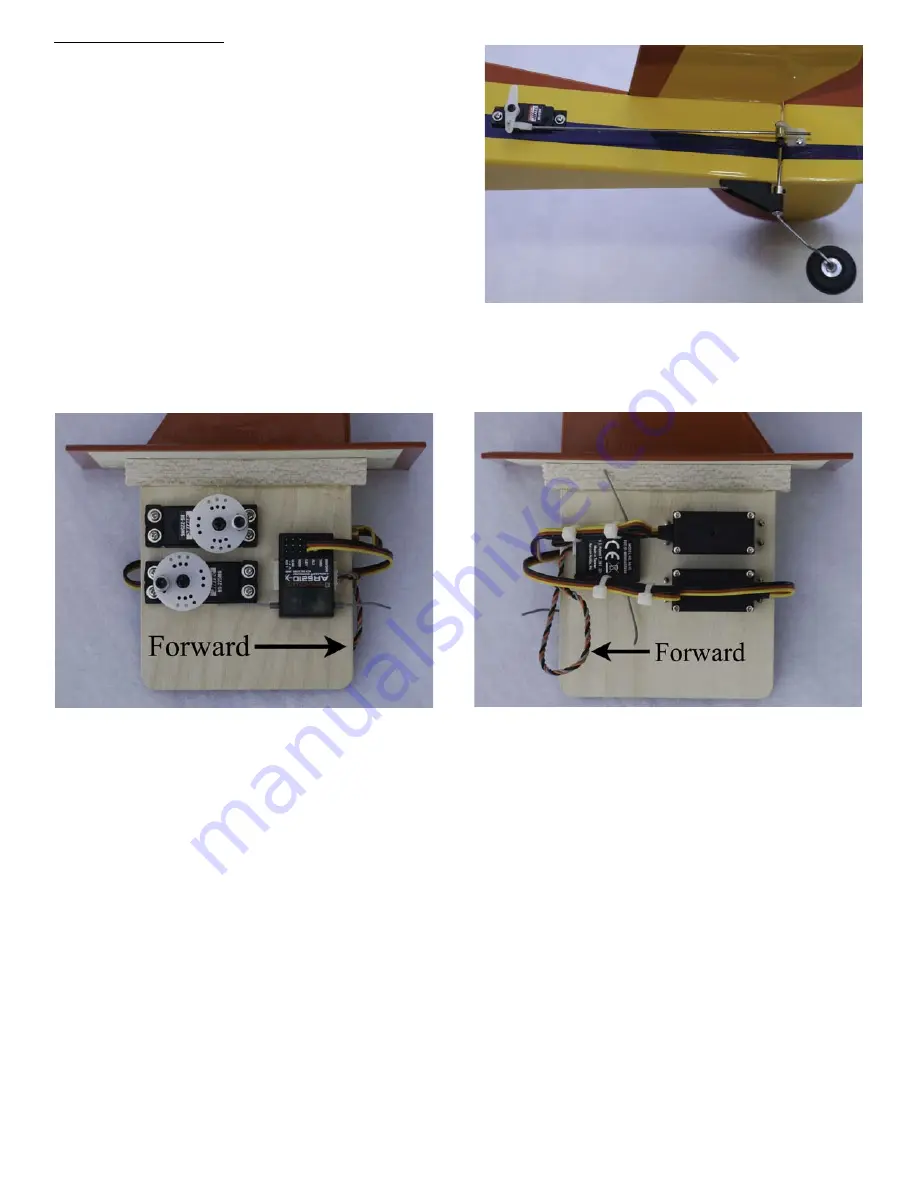

Figure 1

Figure 2

40)

The pylon assembly is semi-self contained. There are only two connections external to the pylon assembly,

the rudder servo and the ESC. The servo cutouts in the pylon core are sized and located for the recommended

Hitec HS-225mg servos. If you decide to use servos other than HS-225mg's, you will need to make sure the

linkage geometry is correct to prevent binding. The upper servo is for roll control and the lower servo is for

pitch control. Simply install the rubber grommets and brass eyelets and then using the screws supplied with the

servos, attach the servos to the pylon as shown in Figure 1 above. The holes are already pilot drilled for the

screws. The prototype used a Spektrum AR6210 receiver. Both the main and remote receivers are attached

using double sided foam tape squares. Ensure both receivers are high enough on the pylon to clear the lower

pylon support in the fuselage. Form loops in the excess servo lead wires are secure with small ty-wraps. Figures

1 and 2 above show how the prototype was done. Use the large round servo wheel that come with the servos.

The smaller straight servo arms could possibly flex under flight loads. You will need to remove the servo wheel

from the servo to install the EZ connectors. Use the center hole in the group of 3 servo wheel holes as shown in

figure 1. The EZ connector shaft measures .092” so the holes in the servo wheel need to be reamed to fit the

connector. Either a #42 or 3/32” drill bit will work. Insert the connector into the servo wheel and secure with the

locking washer. An easy way to drive the washer onto the connector shaft is to use a small 1/4” drive “deep”

socket

and carefully hammer the lock washer onto the shaft. Go slow and carefully because this is a 'one time'

try. The lock washer is not re-usable. Do not hammer the washer down so tight that the EZ connector will not

rotate.

16