HPXM USER INSTRUCTIONS ENGLISH 14983571 - 03/11

Page 13 of 48

and then through the volute to the discharge nozzle.

The casing has mounting feet integrally cast on the

centerline of the pump thus giving a rigid construction

and preventing distortion in high temperature

applications.

3.3.2 Inner casing cover

The inner casing cover is bolted onto the casing

cover. The volute design is of the constant-velocity

type which provides a continuous rise to shutoff while

minimizing radial thrust loads. The result is a pump

with low flow stability.

The volute insert is custom machined for each

application; this results in the best efficiency point for

any given set of hydraulics.

3.3.3 Impeller

The impeller has a full-back-shrouded radial-vane

design with a unique balancing configuration. The

impeller is dynamically balanced, keyed to the shaft

and secured by locknut and lockscrew.

3.3.4 Inducer

Inducers are available on most pump models for low

NPSH conditions. The inducer replaces the standard

impeller locknut and lockscrew. It is secured by

proper cap nut and security washer.

3.3.5 Casing cover

The casing cover is either fabricated from plate or

cast, depending on the material of construction.

Designed to the dimensional standards within the API

682 specification 'Table 1', the seal chamber can

accommodate a wide variety of single or dual seal

arrangements as standard.

3.3.6 Shaft

The shaft is of ample strength and rigidity. It is

precision machined over its entire length and has

generous fillet radii at each change of section to

reduce stress concentrations. Shaft deflections at the

seal chamber are minimal and fall within the

guidelines stated in API 610 8th Edition.

An optional extra heavy duty shaft design, with very

low l3/d4 values, is available on most centerline

discharge pump sizes.

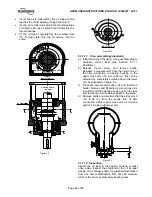

3.3.7 Bearing housing

The bearing housing is fitted with an end cover on the

outboard end for ease of inspection and

maintenance. Each end of the housing is fitted with a

standard labyrinth type shaft seal (made from non-

sparking materials) to effectively retain the oil and

prevent entry of any foreign matter. Special

outsourced baring isolators are available as an

option. The standard bearing lubrication is provided

by a shaft mounted metal slinger that transfers oil to

bearing feed galleries within the housing wall.

Ring oil lubrication is optional. Two metal slingers are

positively locked on the shaft with set screws and

bearing lubrication is provided by a heavy duty oil

ring. A plugged port on the top of the bearing housing

is positioned to allow visual inspection of the oil ring.

Oil mist lubrication is optional; “Purge” oil mist

provisions are available on either slinger or ring oil

designs. “Pure” oil mist (no slinger, no oil ring) is also

available. TRICO constant level oiler is supplied as

standard. For purge oil mist, a balanced type oiler is

used. No oiler is supplied for pure oil mist. When

application requires, the standard cooling system is a

fan, either with slinger or oil ring lubrication. Optional

water cooling is available, should this be a customer

preference.

3.3.8 Pump bearings and lubrication

Heavy duty, single row deep groove radial bearing

and duplex angular contact thrust bearings arranged

back to back ensure long life under the most severe

operating conditions. The bearings have a sliding fit

in the bearing housing and a light interference fit on

the shaft in accordance with AFBMA

recommendations. Lubrication of the bearings is

provided by oil rings, thrower, purge mist or pure mist

as a customer option.

3.3.9 Shaft seal

The mechanical seal(s), attached to the pump shaft,

seals the pumped liquid from the environment. Gland

packing may be fitted as an option.

3.3.10 Driver

The driver is normally an electric motor. Different

drive configurations may be fitted such as internal

combustion engines, turbines, hydraulic motors etc

driving via couplings, belts, gearboxes etc.

3.3.11 Coupling/Coupling guards

Flexible spacer couplings are provided in various

makes and models to suit customer preference.

(Aluminium non- hinged guards are provided)

3.3.12 Baseplate

Standard baseplates are welded steel, drain pan type

in conformance with API 610 standardised

dimensions. Horizontal driver alignment screws and

vertical baseplate levelling screws are provided when

required by API.

Special baseplates can be supplied to suit individual

installation circumstances

.