Installation and Maintenance Manual

Series 19 - Segmented Ball Valves

Date: Feb 2013 / Page 16 of 19

Installation and Maintenance Manual

Series 19 - Segmented Ball Valves

Date: Feb 2013 / Page 17 of 19

®

®

A Subsidiary of BRAY INTERNATIONAL, Inc.

A Subsidiary of BRAY INTERNATIONAL, Inc.

FLOW-TEK, Inc.

Tel: 832.912.2300

© 2012 Flow-Tek, Inc.

8323 N. Eldridge Pkwy #100

Fax: 832.912.2301

Houston, Texas 77041

www.flow-tek.com

FLOW-TEK, Inc.

Tel: 832.912.2300

© 2012 Flow-Tek, Inc.

8323 N. Eldridge Pkwy #100

Fax: 832.912.2301

Houston, Texas 77041

www.flow-tek.com

12. Push packing (13) and bearings (6, 7) out of the body

using a soft metal (bronze) dowel with the appropriate

diameter. Push packing out of the body from the center

of the valve.

11.3 - Reassembling the Valve

To reassemble the body subassembly, refer to the Parts Diagram.

1. Clean all parts and replace all O-rings and soft seals.

2. Check the segment (5) sealing surface to make sure it is

smooth and free of scoring and scratches.

CAUTION:

Damaged or dirty seal surfaces can cause

excessive seat wear and high torque requirements.

Damaged segment should be replaced.

3. Inspect the stem (8) and end post (9) for scratches or

galled surfaces. If damage exists, replace the stem or

contact the factory representative.

NOTE:

Segment and stem are interchangeable. Replacing

the segment does not require replacing the stem.

4. Using a press to install new bearings in the body is

recommended. (Optional post/bearing tool is available

from the factory -

See Table 4 on page 17

) when

correctly installed, the ends of the body bearings (6, 7)

should be flush with the inside of the body.

5. Position the segment (5) in the body by lowering it,

splined hole first, into the back of the body. Rotate the

segment surface toward the front of the body so that the

splined hole is toward the packing box.

CAUTION:

Be extremely careful not to gall or scratch

the sealing surface of the segment when replacing it in

the body. Scratches may later cause excessive leakage

and seal wear.

6. Insert the stem (8) through the post end of body and through

the splined hole of the segment into the packing box.

7. Position the stem so that the pin hole in the stem (8) and

Segment (5) are in alignment. (Stem (8) across flat on

the top and pin holes are perpendicular to each other).

Install the stem pin (10) and drive it firmly into place so

that half is in the Segment (5) and half in the stem (8).

8. Insert the end post (9) into the body. Posts have a half

circle mark on the end. Align this mark with the Segment.

Install the end post pin (11) and drive it firmly into place

so that half is in the Segment and half is in the post.

9. Install the post cover (20) with gasket (19), tighten the

nuts (23) to the required torque per Table-3.

10. Slide thrust washer (12), packing spacer (13A), packing

(13), and gland ring (14) over the double D end of the

stem and into packing box bore.

NOTE:

Always use new packing whenever rebuilding

the packing box.

CAUTION:

Since the sealing on V-ring packing takes

place at the feather edge, it is imperative to avoid

damage to that edge.

11. Reinstall the gland retainer (15) and packing nuts (18)

and leave loose.

CAUTION:

Do not over tighten packing. This can cause

excessive packing wear and stem friction, which may

impede stem rotation.

12. Place the valve on a flat surface with the threaded

(retainer) port facing up and pull the stem (8) toward

the actuator until it is fully against the thrust washer (12).

13. Make certain the segment surface facing up and

position the segment as close as possible in the center

of the body‘s inside diameter. (The pinned connection

between the segment and stem is not a tight connection.

The design includes a considerable amount of axial play

between the segment and stem.)

14. Lubricate the seat O-ring (4) and install into the seat (2).

15. Lubricate the seat retainer O-ring (4A) and install into the

Seat Retainer (2A).

16. Lubricate the mating surfaces between the seat (2) and

seat retainer (2A).

17. Place Wave springs (3) & shim (3A) set in the seat

retainer.

18. Place the seat (2) into seat retainer (2A), so the seat is

resting on the shims and wave springs.

19. For metal seat, lubricate the contact surfaces between

the seat and segment.

20. Replace the O-rings (4B) in the seat retainer (2A) (except

on high temperature valves, which do not use O-rings).

Refer to Figure 13. Lubricate the seat retainer threads

and O-rings and reinstall the retainer in the body. Torque

the seat retainer according to

Table 2

.

21. After the seat retainer is tightened, tighten the packing

nuts (18) just over finger-tight. Packing nuts (18) should

be tightened as necessary to prevent stem leakage.

CAUTION:

Do not over tighten packing. This can cause

excessive packing wear and high stem friction, which

may retard stem rotation.

11.4 Remounting the Actuator

1. Before mounting an actuator on the valve body, verify

that the Segment rotation matches the actuator rotation

and complies with the air/signal failure requirements.

Procedure for mounting the actuator is as follows.

2. Bolt the Bracket on to the body, if it is removed.

3. Slide the entire actuator assembly onto the stem by

ensuring the desired actuator orientation. (Please refer

to the actuator IOM for necessary adjustments on the

assembling with valve).

4. Tighten the actuator mounting bolts.

5. Install valve in pipe line as outlined in Section 4.

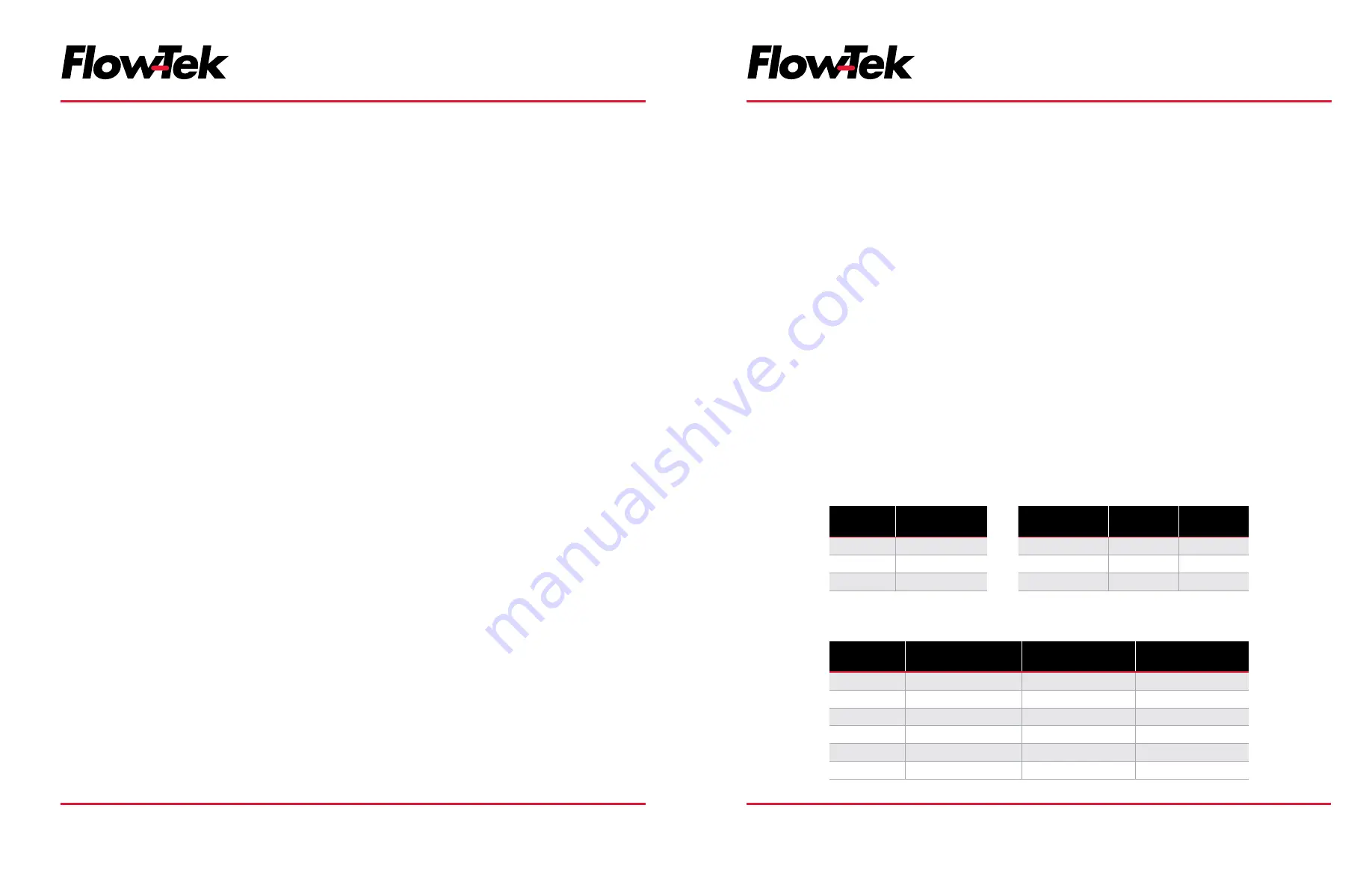

Table 2:

Retainer Torques

Valve Size

(inches)

Torque Value

(N-m)

1, 1.5, 2

200-240

3

340-410

4, 6

750-820

Table 4:

Assembly Tools (Optional upon request)

Valve Size

Retainer Tool Part No.

Stem Bearing Press

Tool Part No.

Post Bearing Press

Tool Part No.

1” (DN 25)

9N-0000-00466

9N-0000-00471

9N-0000-00476

1.5” (DN 40) 9N-0000-00467

9N-0000-00472

9N-0000-00477

2” (DN 50)

9N-0000-00468

9N-0000-00473

9N-0000-00478

3” (DN 80)

9N-0000-00445

9N-0000-00448

9N-0000-00449

4” (DN 100)

9N-0000-00469

9N-0000-00474

9N-0000-00479

6” (DN 150)

9N-0000-00470

9N-0000-00475

9N-0000-00480

Table 3:

Lubricated Screw Tightening Torques

Stud Size

A193-B7

& B7M

A193-B8

1/4”-20 UNC

5 Nm

2 Nm

5/16”-18 UNC

10 Nm

4.5 Nm

3/8”-16 UNC

18 Nm

8 Nm