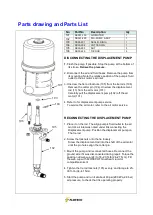

Displacement Pump Service

Disassembly

When disassembling the pump, lay out all removed

parts in sequence, to ease reassembly.

Clean all the parts thoroughly when disassembling.

Check them carefully for damage or wear, replacing

parts as needed.

1. Remove the displacement pump from the air

motor

as explained.

2. Unscrew the intake valve housing (19) from the

pump housing (9). If it is difficult to remove, squirt

penetrating oil around the threads and

gently

tap

around the valve housing with a plastic hammer

to

loosen it.

3. Remove the ball stop pin (15), o–ring(17),

retainer (16), and ball (18), ball guide(22), from

the intake housing (19).

4. Loosen the packing nut (24). Push the

displacement

rod (12) down as far as possible, then pull it out

the bottom of the pump housing (9).

5. Secure the flats of the displacement rod (12) in a

vise. Screw the piston stud(14) out of the rod .

Remove the ball(13), reatainer(21), packings(5,6)

And glands(4,7).

6. Remove the packing nut (24), throat packings

(5.6)

and glands (4,7) from the pump housing (9).

7. Inspect all parts for damage. Clean all parts and

threads with a compatible solvent before

assembling. Inspect the polished surfaces of the

displacement rod (12) and sleeve (11) for

scratches,

scoring or other damage, which can cause

premature packing wear and leaking. To check,

run a finger over the surface or hold the part up

to the

light at an angle. Be sure the ball seats of the

piston and intake housing are not chipped or

nicked. Replace any worn or damaged parts.

NOTE:

If the sleeve (11) needs replacement and is

hard to remove, contact your FLOTECH

distributor.

Reassembly

1.

Lubricate the throat packings and install them in

The outlet housing (9) one at a time as follows,

with the lips of the v–packings facing down:

the

male gland (4), one teflon (6), two leather(5),

one teflon (6), one leather (5), one teflon (6),

and the female gland (7). Install the packing nut

(24) loosely. See the throat packing detail.

2.

If you removed the sleeve (11), reinstall it in the

pump housing (9), making sure to replace the

gasket (10).

Be sure the tapered end of the

sleeve

faces down, toward the pump intake.

3. Lubricate the piston packings and install them

onto

the piston stud (14) one at a time in the

following

order,

with the lips of the v–packings facing up:

the

female gland (7), one Teflon (6), two leather (5),

one Teflon (6), one leather (5), one Teflon (6),

the male gland (4), and the packing retainer

(21). See the piston packing detail.

4. DO NOT use thread sealant on the piston

stud(14)

Install the piston ball (13) on the piston and

screw

the piston valve assembly into the displacement

rod (12). Torque to 65–75 ft–lb (88–102 N.m).

5. Insert the displacement rod (12) into the bottom

of

the pump housing (9), being careful not to

scratch

the sleeve (11). Push the rod straight up until it

protrudes from the packing nut (24).

6. Install the ball (18), o–ring (17), retainer(16),

and ball stop pin (15), ball guide(22), in the

intake valve housing (19). Apply thread

lubricant and Screw the intake housing into the

pump housing (9). Torque to 75–100 ft–lb

(102–136 N.m).

7. Reconnect the displacement pump to the air

motor as explained.