Flomatic Corp, 15 Pruyn’s Island, Glens Falls, New York 12801

Phone: 518-761-9797 Fax: 518-761-9798 www.flomatic.com

745PI-BF-LS-ASC Rev. B

October 12, 2018

INSTALLATION

Correct installation of the Flomatic

®

Flo-Flex

®

is important for proper

operation. It may be installed in either horizontal or vertical flow-up

applications. Horizontal installation, with the access port facing up is

recommended for waste water application as it will prevent material

in the fluid to collect on the valve disc. In all installations, the flow

arrow cast in the valve and cover must be pointed in the direction of

flow.

Flanged valves should only be mated with flat-faced pipe flanges

equipped with full-face resilient gaskets. The valve and adjacent

piping must be supported and aligned to prevent cantilevered stress

on the valve. Once the flange bolts or studs are lubricated and

inserted around the flange, tighten them uniformly hand tight. The

tightening of the bolts should then be done in graduated steps using

the

crossover tightening

method. Recommended lubricated torque

values for use with resilient gaskets (75 durometer) are given in Table 1. If leakage occurs, allow gaskets to absorb fluid

and check torque and leakage after 24 hours. Do not exceed bolt rating or the flange gasket can get damaged and extrude.

TROUBLESHOOTING

Below are some potential problems with solutions to assist you in troubleshooting the valve assembly in a safe manner.

Also, visit Flomatic

®

web page

www.flomatic.com

for technical product references and parts lists or call customer service 1-800-833-2040.

MAINTENANCE

The Flomatic

®

Flo-Flex

®

Swing Check Valve requires no scheduled lubrication or maintenance. For service or inspection,

the valves internal parts can be accessed and serviced without removal from the line.

WARNING: The line must be drained and de-pressurized before removing the cover or the bottom plug if

not this may cause bodily harm.

VALVE INSPECTION: DISASSEMBLY & RE-ASSEMBLY

The valves internal parts can be disassembled and serviced without removing it from the pipeline. All service and repair

work performed on the valve shall be performed by a skilled mechanic with proper tools and a power hoist for larger

valves. It is recommended that when disassemble the valve to inspect the rubber valve disc for wear or the valve seat for

deposits.

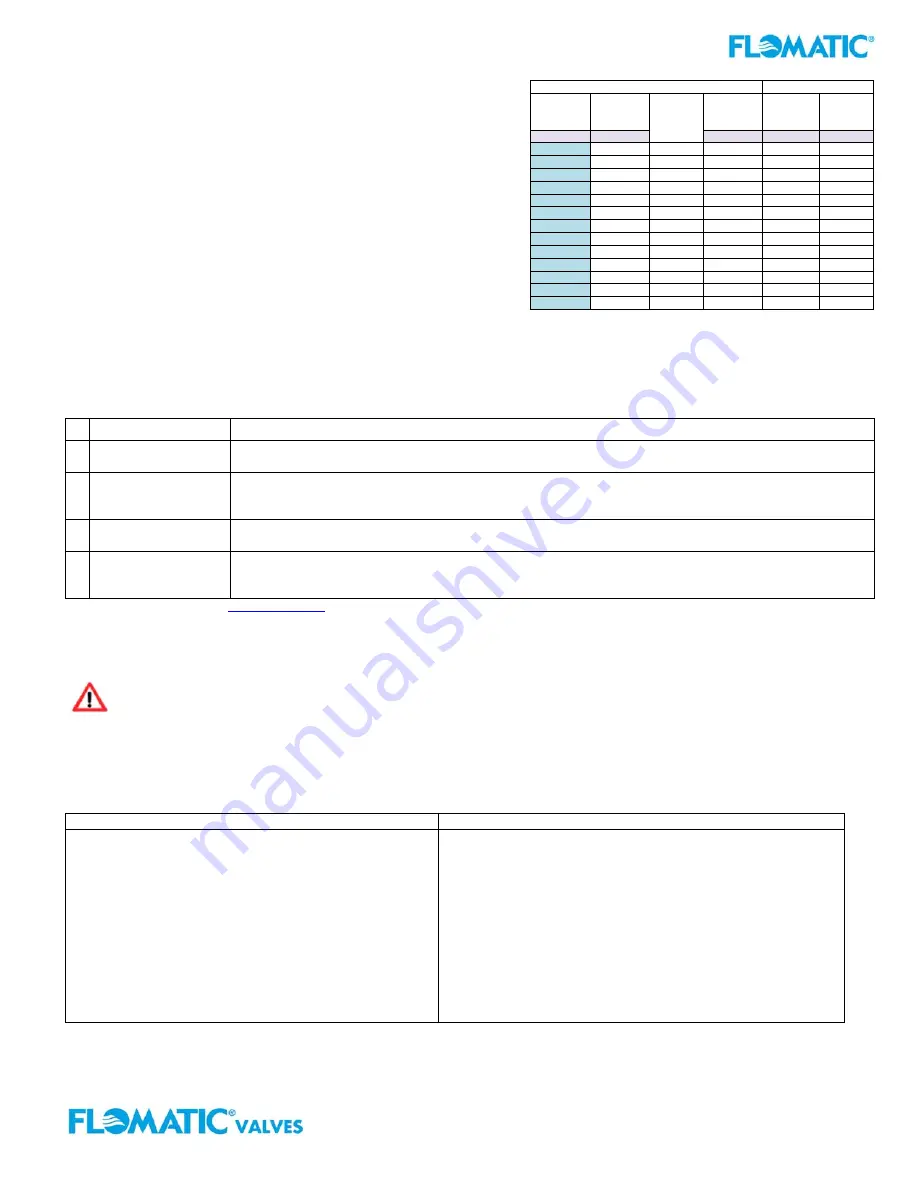

Dimensions for 150# Class Valves

Max Torque

Valve

Size

Flange

Outside

Diameter

Number

of Bolt

Holes

Bolt

Diameter

150# 300#

(inches)

(inches)

(inches)

(ft.-lbs.)

(ft.-lbs.)

2 6 4

5/8”

90

90

2-1/2 7 4 5/8” 90 150

3 7-1/2 4 5/8” 90 150

4 9 8

5/8”

90

150

6 11 8

3/4”

150

150

8 13-1/2 8 3/4” 150 240

10 16 12

7/8”

240

368

12 19 12

7/8”

240

533

14 21 12 1” 368

533

16 23-1/2 16 1” 368 750

18 25 16

1-1/8”

533

750

20 27-1/2 20 1-1/8” 533 750

24 32 20

1-1/4”

750

1200

Table 1

Bolt Torque Chart

Problem Solution

1

Valve disc leaks-

back when closed

Inspect valve seat area for foreign material. Also, inspect disc for damage and replace. Inspect metal

seating surface and clean if necessary

2

Leakage at bottom

Back-flush device

Remove line pressure and exercise Back-flush device. If leak persists, replace seals in Back-flush

device; see the Back-flush device “Seal Replacement Procedure” on page 4.

3

Leakage at Cover or

Flanges

Tighten bolts, replace cover seal.

4

Valve does not fully

open:

Check for obstruction in valve seat area and/or pipeline; see Disassembly procedure on page 4.

Operating pressure may be less than cracking pressure. If less than 0.5 psig, review application with

factory.

DISASSEMBLY

RE-ASSEMBLY

1. Relieve pressure and drain the pipeline. Refer to

Figure 2 on page 2. Remove the cover bolts (5)

on the top cover.

2. Pry cover (2) loose and lift off valve body. 12” and

larger valves have tapped holes in cover for lifting

eyes.

3. Remove disc (3) and inspect for cracks, tears or

damage in rubber sealing surface.

4.

Clean and inspect parts. Replace worn parts as

necessary and lubricate parts with FDA/NSF

grease such as “Super Lube”.

All parts must be cleaned. Gasket surfaces should be cleaned

with a stiff wire brush in the direction of the serrations or machine

marks. Worn parts, gaskets and seals should be replaced during

reassembly.

1. Lay disc (3) over seat with beaded seating surface

directed down.

2. Lay cover gasket (4) and cover (2) over bolt holes and

disc hinge.

3. Insert lubricated bolts (5) noting that the bolts in the

hinge area are longer than the other cover bolts.

4.

Cover bolts should be tightened to the specifications

shown in

Table 2

(next page) during re-assembly.