18

ZAPEX 3502 en

Operating instructions 10/2017

6.

Fitting

Observe the instructions in section 3, "Safety instructions"!

If a dimensioned drawing has been made out for the coupling, the data in this drawing

must be given priority.

6.1

Instructions for applying the finished bore and fitting the axial retaining means, set screws and balancing

According to the order placed, the coupling parts (1/2) for removal by oil-hydraulic shrinking off are

delivered with finished bores.

6.1.1

Finished bore for parallel-key connection

•

Depreserve coupling parts (1/2).

Note manufacturer’s instructions for handling solvent.

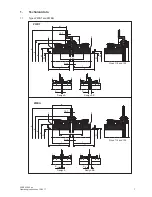

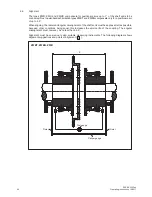

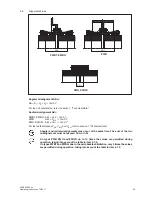

For making the finished bore, the coupling parts must be clamped as shown in the following figure.

The clamping chuck must always be opposite the sealing surface.

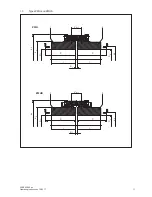

The coupling part must be aligned carefully. For the permissible radial eccentricity see DIN ISO 286 degree

of fundamental tolerance IT 6 (see table 6.1).

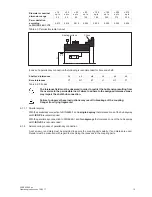

The maximum permissible bore diameters (see section 1) are designed for

parallel-key connections without taper action to DIN 6885/1 and must not under any

circumstances be exceeded.

When the keyway is to be designed deviating from DIN 6885/1 for a parallel-key

connection, Flender should be consulted.

If other shaft-hub connections (e.g. spline bore hub profile, tapered or stepped bores, parallel-key

connections with tightening) are to be used instead of the provided parallel-key connection, Flender

should be consulted.

Failure to observe these instructions may result in breakage of the coupling.

Danger from flying fragments!

Содержание Zapex ZWB

Страница 2: ......