GLEB Kitchen exhaust fan

12

A

ll

ri

g

h

ts

r

e

s

e

rv

e

d

.

V

e

rs

io

n

1

/2

0

1

3

©

F

lä

k

t

W

o

o

d

s

O

y

7.3 Replacing the motor

The fan has to be disconnected from the duct system

and mains before the motor can be replaced.

1. Check that the motor is disconnected from mains.

2. Open the cleaning hathc(es).

3. Measure the overlap between the impeller and

the inlet cone.

4. Open the impeller locking screw from the motor

shaft end and make sure that the impeller is

moving on shaft, if necessary use the extraction

tool.

5. Remove the motor bolts.

6. Remove the impeller from the shaft by pulling the

motor carefully backwards, take care that the

impeller remains in its place, securely supported

by the inlet cone and the hub.

7. Insert the new motor.

8. Insert the motor bolts.

9. Insert and tighten the impeller locking screw.

10. Check that the overlap is same as measured before and the impeller and the inlet cone are

precisely aligned.

11. Tighten the motor bolts.

12. Close the cleaning hathc(es).

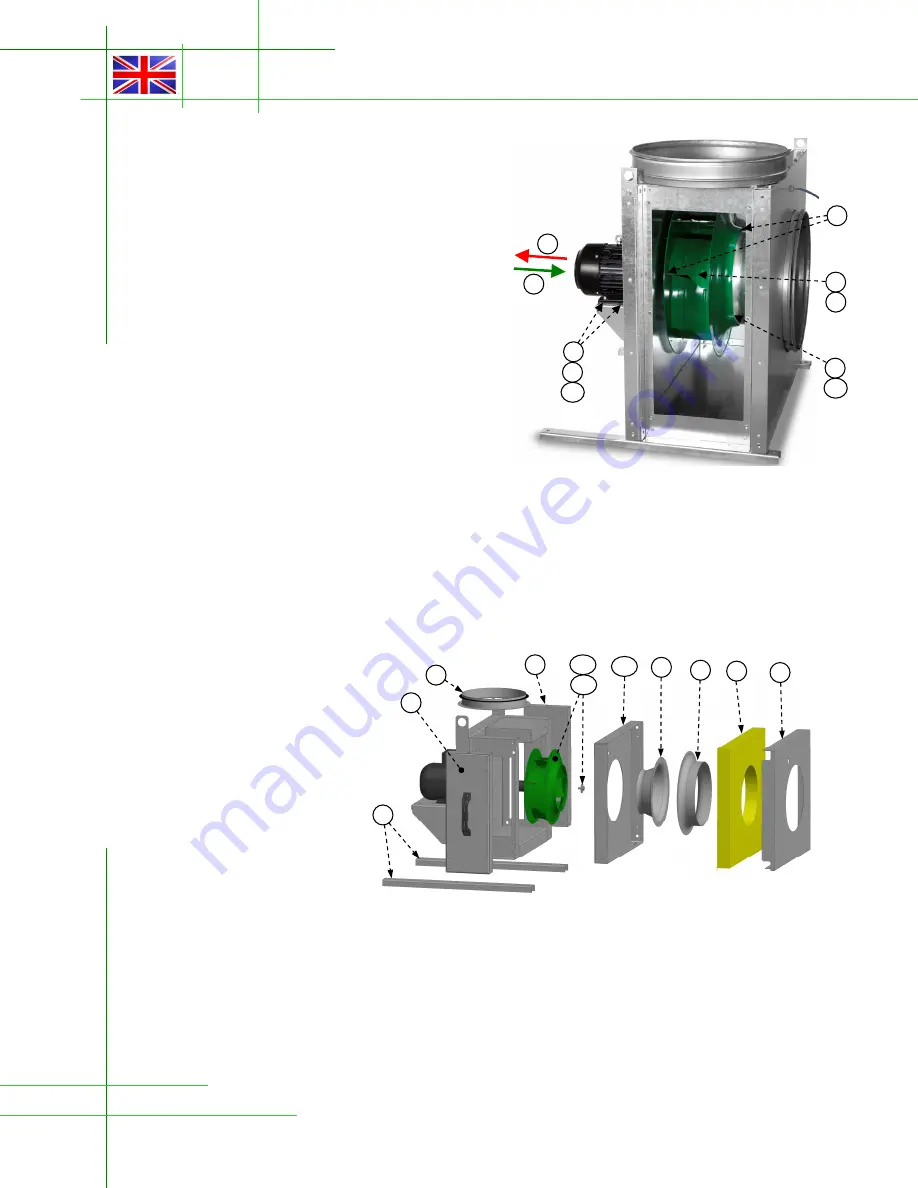

7.4 Replacing the impeller

The fan has to be disconnected from the duct system before the impeller can be replaced.

1. Check that the motor is disconnected from mains.

2. Open the cleaning hathc(es).

3. Measure the overlap between

the impeller and the inlet

cone.

4. Detach the outlet connection.

5. Detach the standing skids.

6. Detach the outer panel of

front plate.

7. Take out the insulation wool.

8. Detach the inlet connection.

9. Detach the inlet cone.

10. Detach the front plate, note

that there is a fire-resistant

sealing compound between

the front plate and the rest of

the casing

11. Open the impeller locking screw from the motor shaft end and pull out the impeller, if necessary

use the extraction tool.

12. Insert the new impeller and tighten the impeller locking screw.

13. Insert the rest of the parts in reversed order that they were dismantled.

Remember to renew the sealing of the casing with a fire-resistant sealing compound!

Remember to check that the overlap is same as measured before and the impeller and the inlet cone

are precisely aligned!

4

3

6

7

5

1 1

1 0

9

8

6

2

6

7

8

9

1 2

4

2

5

1 0

1 1