C1 Controllers and Transmitters

Instruction Manual

September 2009

27

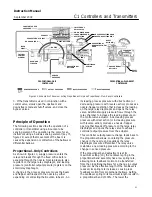

CONNECTING

LINK (KEY 16)

PROPERLY ALIGNED

CONNECTING LINK

BINDING CONNECTING LINK

(IMPROPERLY ALIGNED)

BEAM

(KEY 39)

WASHER

(KEY 62)

LINK BEARING

(KEY 31)

BOURDON TUBE

(KEY 5)

WASHER

(KEY 62)

BOURDON TUBE

(KEY 5)

LINK BEARING

(KEY 31)

WASHER (QTY 2)

(KEY 62)

BEAM

(KEY 39)

CONNECTING LINK

(KEY 16)

GE37119

Figure 17. Connecting Link

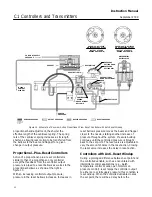

10. Replace the subassembly in the case and

secure with the four machine screws (key 41,

figure 21 or 22). Reconnect all tubing.

11. If a bellows assembly with a different range is

installed, remove the machine screw and washer

(keys 61 and 60) and dial (key 6), and install a new

dial having an adjustment range corresponding to

the range of the bellows. If an optional process

pressure gauge (key 4, figure 21) is being used,

install a new gauge with the appropriate

measurement capability.

12. Check all tubing connections for leaks and the

bellows yoke machine screws, tighten as necessary.

Perform the appropriate calibration procedures.

Changing Reset Valve

1. Disconnect the appropriate tubing and remove

the reset restriction valve assembly (key 256,

figure 22) by removing the screw (key 22, not

shown) from the back of the case. Install the desired

replacement assembly.

2. Connect the tubing, check all connections for

leaks and perform the appropriate calibration

procedures.

Changing Anti

−

Reset Windup

Differential Relief Valve

Refer to figure 23 for key number locations.

1. Note the controller output pressure (zero or

supply) when the process is shut down.

2. Remove the differential relief valve assembly.

3. Refer to figure 14. Install the replacement relief

valve with the arrow positioned so that the controller

output will be as noted in step 1 when the process is

shut down.

Changing Action

Proportional

−

Only to a Differential Gap

Controller

A proportional

−

only controller may be changed to a

differential gap controller, or vice versa, by changing

the position of the proportional tubing and inverting

the proportional band assembly.

1. Isolate the controller or transmitter from process,

control, and supply pressure. Vent any trapped

pressure from the controller or transmitter before

proceeding with the following steps.

2. Disconnect the proportional tubing (key 25,

figure 16) from the mounting base (key 57, figure 23

or 24) and reinstall it in the other connection in the

mounting base.

3. Do not invert the reversing block unless also

changing the controller action from direct to reverse

(or vice versa).

4. Invert the proportional band assembly (refer to

figure 18):

a. Turn the proportional band adjustment knob

(key 73) to 10.

b. Unscrew the spring adjustor (key 65),

removing the bias spring (key 70) and washers

(key 64) with it.