C1 Controllers and Transmitters

Instruction Manual

September 2009

20

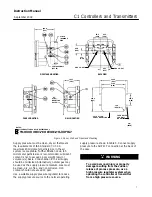

IF OUTPUT IS:

MOVE ADJUSTER

LEFT

MOVE ADJUSTER

RIGHT

NOTE:

3 TO 15 PSIG (0.2 TO 1.0 BAR) OUTPUT SHOWN.

FOR 6 TO 30 PSIG (0.4 TO 2.0 BAR) OUTPUT, ADJUST

VALUES AS APPROPRIATE.

A6156 / IL

ABOVE

15 PSIG

(1.0 BAR)

BELOW

15 PSIG

(1.0 BAR)

Figure 12. Transmitter Span Adjustment

3. Verify that the calibration adjuster screws

(key 48) are at mid

−

position in the calibration

adjuster (key 36) slots.

Depending upon the transmitter action, perform one

or the other of the following procedures.

For reverse

−

acting transmitters:

4. Rotate the zero adjustment knob to zero.

5. Apply an input pressure equal to the sensing

element upper range limit.

6. Adjust the nozzle (key 57) until the transmitter

output pressure is at 0.2 bar (3 psig).

7. Set the input pressure equal to zero.

Note

Proper transmitter response depends

on nozzle

−

to

−

flapper alignment.

When performing the span adjustment

in step 8, carefully loosen both

calibration adjuster screws while

holding the calibration adjuster in

place. Then move the calibration

adjuster slightly in the required

direction by hand or using a

screwdriver. Verify proper

nozzle

−

to

−

flapper alignment and hold

the calibration adjuster in place while

tightening both adjustment screws.

8. If the output pressure is not 15 psig, adjust the

span by loosening the two adjusting screws (key 48)

and moving the calibration adjuster (key 36) a small

distance as indicated in figure 12.

9. Repeat steps 4 through 8 until no further

adjustment is necessary.

10. Proceed to the startup procedure for

transmitters.

For direct

−

acting transmitters:

4. Rotate the zero adjustment knob to zero.

5. Set the input pressure to zero.

6. Adjust the nozzle (key 54) until the transmitter

output pressure is at 0.2 bar (3 psig).

7. Apply an input pressure equal to the sensing

element upper range value.

Note

Proper transmitter response depends

on nozzle

−

to

−

flapper alignment.

When performing the span adjustment

in step 8, carefully loosen both

calibration adjuster screws while

holding the calibration adjuster in

place. Then move the calibration

adjuster slightly in the required

direction by hand or using a

screwdriver. Verify proper

nozzle

−

to

−

flapper alignment and hold

the calibration adjuster in place while

tightening both adjustment screws.

8. If the output pressure is not 15 psig, adjust the

span by loosening the two adjusting screws (key 48)

and moving the calibration adjuster (key 36) a small

distance as indicated in figure 12.

9. Repeat steps 4 through 8 until no further

adjustment is necessary.

10. Proceed to the startup procedure for

transmitters.

Startup: Transmitters

1. Be sure that the supply pressure regulator is

delivering the proper supply pressure to the

transmitter.

2. Refer to the calibration procedures for the

transmitter initial settings.