Type 9500

4

O-rings on the liner faces. Leakage through the

flange connections and damage to the liner could

result if the partial O-ring faces are not properly

supported.

The 6 to 10-inch sizes must not be used with slip-on

flanges unless flange adaptors are used to support the

liner. When using slip-on flanges with other sizes, be

certain the valve is carefully centered to ensure that the

partial O-ring faces are in full contact with the adjacent

flanges.

c. When a flange adpater is necessary, a flange

gasket must be installed between the line flange

and the flange adapter. Do not use a flange gasket

between the valve and the flange adapter. Addition-

al gasketing material at this location could damage

the liner.

d. The valve disk must be in the closed position

when the valve is being inserted into the pipeline. If

the valve disk is not closed, it could be damaged

against the mating piping or flanges.

6. Insert the valve into the pipeline. Insert four flange

studs or bolts through the flanges to support the valve.

7. Center the valve carefully on the flanges by mea-

suring equal distances at the top and bottom and

equal distances at the sides.

8. Insert the remaining flange studs or bolts. Tighten

the studs or bolts evenly. Normal flange bolt torques

may be used because liner compression is limited by

metal-to-metal contact between flanges and the valve

body.

9. Rotate the valve disk manually to be certain the

disk clears the adjacent piping or flanges as it opens.

If necessary, disconnect the power actuator-valve link-

age, but do not disturb the adjustment of the turn-

buckle or adjustable linkage. If the disk hits the flange,

loosen flange bolting temporarily while re-centering the

valve. If the problem cannot be corrected in this man-

ner, it will be necessary to use line flanges with larger

inside diameters adjacent to the valve.

10. For hazardous atmosphere or oxygen service

valves, read the following Warning, and provide the

bonding strap assembly mentioned below if the valve

is used in an explosive atmosphere.

WARNING

The valve drive shaft is not necessarily

grounded to the pipeline when installed.

Personal injury or property damage

could result, if the process fluid or the

atmosphere around the valve is flam-

mable, from an explosion caused by a

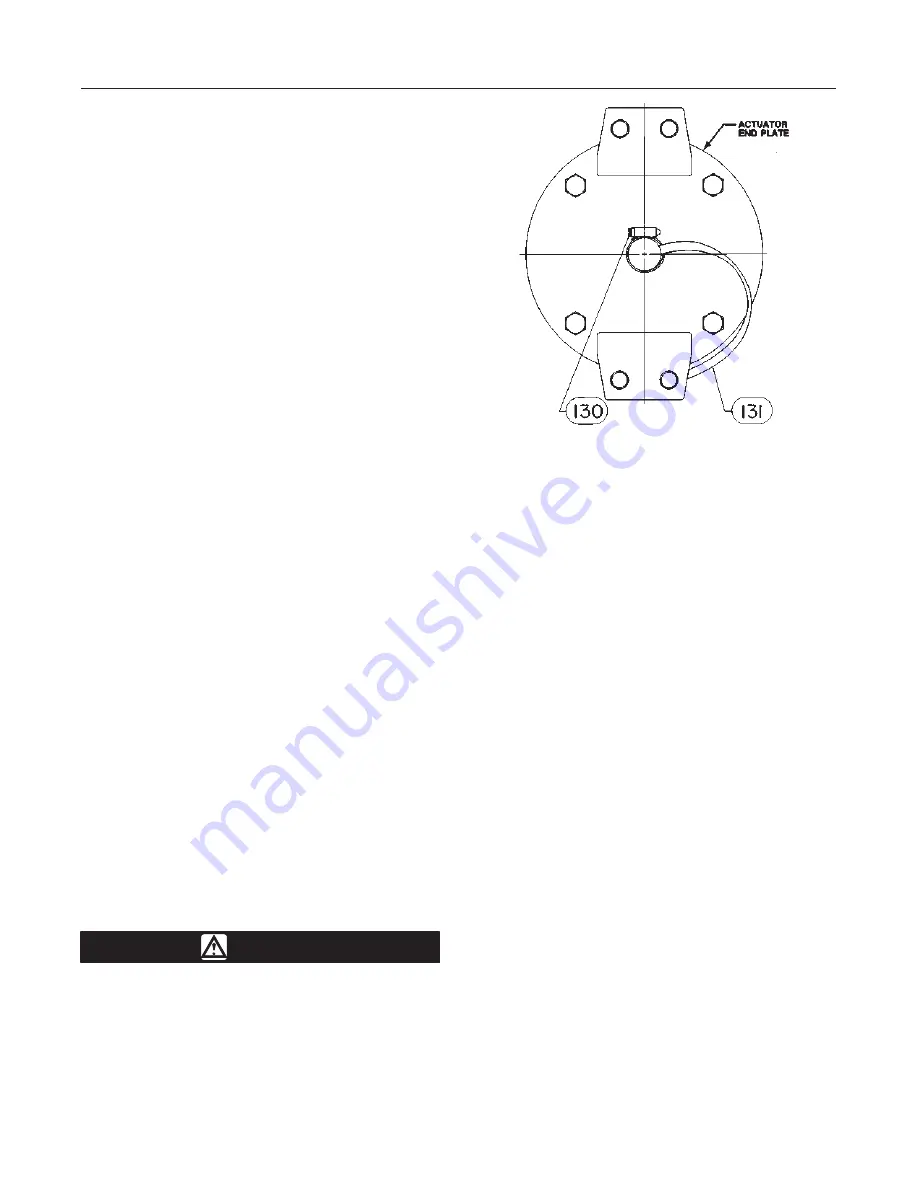

Figure 4. Grounding Assembly

37A6528-A/DOC

discharge of static electricity from the

valve components. If the valve is

installed in a hazardous area, electrical-

ly bond the drive shaft to the valve.

Note

The packing is composed of all conduc-

tive packing rings (graphite ribbon

packing) or partially conductive packing

rings (carbon-filled PTFE female adaptor

with PTFE V-ring packing or graphite-

composition packing ring with PTFE/

composition packing) to electrically

bond the shaft to the valve for hazard-

ous area service. For oxygen service ap-

plications, provide alternate shaft-to-

valve body bonding according to the

following step.

11. Attach the bonding strap assembly (key 131, fig-

ure 4) to the shaft with the clamp (key 130, figure 4).

12. Connect the other end of the bonding strap as-

sembly to the valve flange cap screws.

Adjustments

Hub Seals

Key number locations are shown in figure 7.

Thrust sleeve assemblies (key 6) seal the disk hubs.

In time, especially with frequent valve disk rotation,

these seals may require adjustment.