Page 10

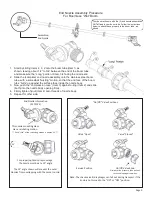

Intake/Siphon Tube/Screen Detail of a Typical L&G/ATV Sprayer (not including the ‘EC’Units)

‘Cut’ View of a ‘Typical’ Tank

(looking inside)

The suction line of your sprayer should contain a ‘siphon tube’ or intake tube which should be rotated so

that it just touches the bottom of the tank surface. (see Detail Views). Reach in and rotate it, as needed, if

not already in this position.

A nylon shut-off valve is threaded onto the pipe nipple at the intake location on the tank. It is at this location

so you can shut off the flow of solution to access your system’s screen for cleaning.

Checking/Cleaning the sprayer’s filter/screen:

i

Start your pump and before it shuts off, reach down and Shut the nylon valve to the ‘Closed’ position

(lever is perpendicular to the flow of fluid), then shut off your pump.

i

Unscrew the knurled nut from the shut-off valve, leaving the valve connected to the tank.

i

Swing (swivel) the intake assembly towards you. Look in the nut you JUST unscrewed. There is a

screen/washer there.

i

Remove the screen and clean as necessary. Replace when done and reassemble the entire assembly.

i

Make sure the valve is turned to the ‘Open’ position before restarting your pump.

Maintenance During/After Spraying

Periodically check the strainer and clean the screen on your intake line. Proper care and maintenance will prolong the life of your sprayer.

After use, fill the sprayer half way with clean water. Start the pump and allow the water to pump through the entire plumbing system and nozzles. Drain

and then refill half full, add the recommended amount of a good quality tank cleaner, such as FIMCO Tank Neutralizer and Cleaner. (If no tank cleaner

is available, you may substitute dish soap for this step). Turn pump on and circulate through system for 15 minutes and then spray out through boom

and handgun nozzles. Refill sprayer half way with clean water and repeat. Follow the chemical manufacturer’s disposal instructions of all wash or

rinsing water.

If boom or handgun nozzles need cleaning, remove them from the sprayer and soak in warm soapy water. Clean with a soft bristled brush or toothpick

if necessary. Never use a metal object. Even the slightest damage can change the flow rate and spray distribution. Water rinse and dry the tips before

storing.

WARNING:

Some chemicals will damage the pump valves if allowed to soak untreated for a length of time! ALWAYS flush the pump as

instructed after each use. DO NOT allow chemicals to sit in the pump for extended times of idleness. Follow the chemical manufacturer’s

instructions on disposal of all waste water from the sprayer.

Storing Sprayer

When sprayer is not in use, release Cam Lock Handles. This is to prevent deforming of Cam Lock Mechanism. Do not use QR bracket Cams to hold

and store boom in vertical position.

Winter Storage

Before storing your sprayer for winter or long term storage, thoroughly clean and drain it as much as possible. Then pour enough pink RV antifreeze

into the tank so that when the pump is turned on you can pump the antifreeze throughout the entire plumbing system, including the bypass. Make sure

to operate the boom and handgun until you see pink fluid spraying from the nozzles. Leave any remaining antifreeze in the tank. Before your next

usage, rinse the antifreeze from the sprayer with clean water.

It is nearly impossible to drain all of the water from the sprayer and any trapped water can freeze in cold weather and damage parts of the sprayer.

Pumping the antifreeze through the system will displace the water and help prevent this damage.