Page 6

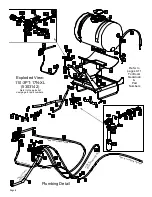

Piston Type Pressure Relief/Regulating Valves

Bypasses excess fluid. Adjustable to maintain control of line pressure at any pressure within the valve operating range.

Selected pressure setting firmly held in place by locknut. Extra large passages to handle large flows.

Polypropylene with stainless steel spring

Excellent chemical resistance

EPDM O-Rings

Fore pressure to 150 p.s.i.

1/4” port for pressure gauge

3/4” NPT (M) inlet & (F) outlet connections

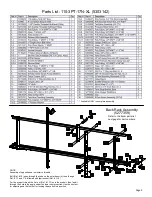

* * Available ONLY in Repair Kit

♦ ♦ ONLY Available in Complete Assembly

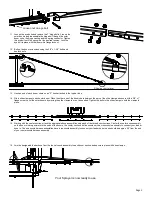

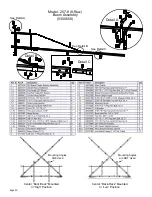

RH boom is ‘selected’

* * = Available ONLY in Repair

Parts Kit #7771795 (3430-0380)

Consists of Rollers, O-Ring &

Viton Seals

♦ ♦ Available ONLY in Complete

Assembly

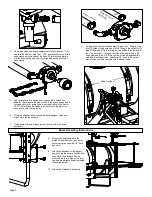

TeeValve Control Valve Model: AA17L (5143295)

Model AA17L, used for selective control of 3-section boom sprayers

at pressures up to 300 PSI.

Use to open any of three boom sections lines in any

desired combination.

Raise lever to open, lower lever to close the valve

without changing the indexed position.

Aluminum construction with stainless steel and plastic

internal parts for maximum corrosion resistance.

3/4” NPT Inlet/Outlet, 3 boom outlet and accessory

outlet.

1/4” NPT Gauge Port

RH boom is ‘activated’

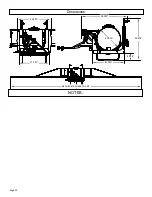

Silver Series 6-Roller Pump Assembly

(#5273024)

(Hypro Mfg. Part # 6500XL)