data: 13/03/03

file: P1X_ing.doc

Rev: 1.1

pag 1 di 11

The P1X is a programmable single-axis positioner with microprocessor with relay outputs that processes

signals supplied by incremental transducers such as encoders, magnetic lines, optical lines, etc.

Positioning is managed through the stop/onward/backward, slow/fast, end of positioning, and auxiliary outputs

and through the optoinsulated start, emergency, reset, and work counter inputs.

The axis dimension is displayed on the high brightness six-digit display (reading scale -99999, +999999) and

three auxiliary displays show the set dimension, the machine constants, and the processing parameters.

The keyboard with 16 keys and 8 function indicators make the positioner use and setting up easy.

The P1X can memorize up to 99 dimensions to create positioning programmes giving the possibility to manage

for every dimension the number of parts that are to be processed in sequence as well as the number of cycle

repetitions. In order to optimize positioning accuracy there are some parameters that can counterbalance

system inertia, clearances, and wear and tear of mechanical couplings.

Find below the other features characterising the instrument:

automatic/semiautomatic, manual functioning modes, absolute/line, single positioning, blade thickness

compensation, zero research, inputs and outputs test; and serial connection RS232 or RS485 with MODBUS

RTU protocol to dialogue with remote units.

The keeping of data when there is no power supply is guaranteed by a non volatile EEPROM memory.

The instrument is enclosed in a panel box 72x144 conforming to the DIN 43700 standard.

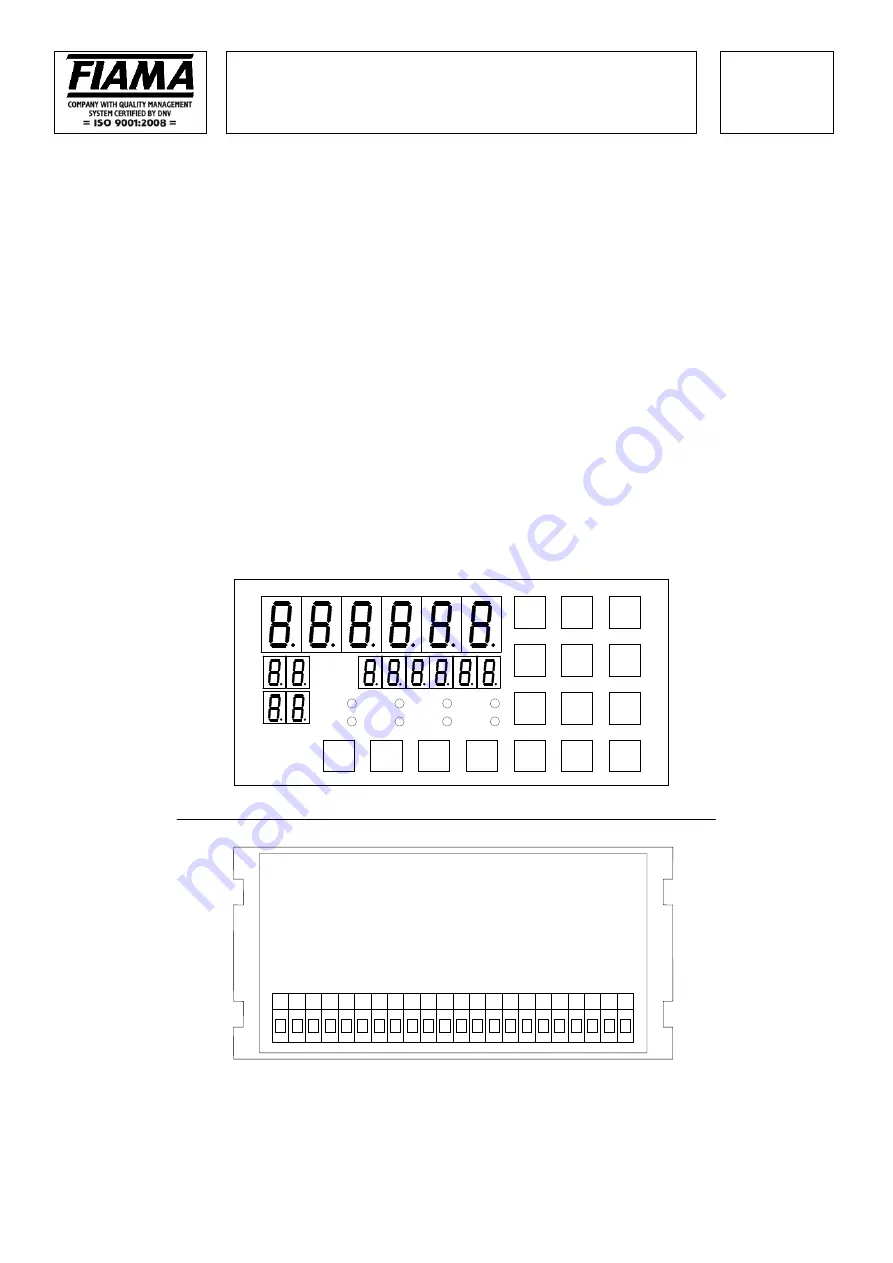

Front view

Back view

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

Positioner P1X

P1X0

P1X1

P1X2

P1X3

+

-

START

STOP

MAN

ZERO

SING

A/S

PROG

COST

TEST

CYCL

1

2

3

4

5

6

7

8

1

2

5

4

3

.

7

8

9

6

<

<<

>>

>

0

C

P

E