AUTORAKE

®

OPERATION (Continued)

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY

INSTRUCTIONS (pages 2-5 of this manual) BEFORE BEGINNING ANY

AUTORAKE

®

OPERATION

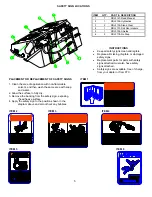

DUMPING

1. Shut off the auxiliary hydraulics.

2. Move to the dump site and park on firm, level ground.

3. Activate the auxiliary hydraulics in the direction opposite of what was used to operate the rake chain. This will retract

the hydraulic cylinder and open the main housing.

4. Raise this product about four feet above the ground.

5. Dump the bucket and reverse the process so that you are ready to resume raking.

AUTORAKE

®

MAINTENANCE

SAFETY FIRST!! READ AND UNDERSTAND THE SAFETY

INSTRUCTIONS (pages 2-5 of this manual) BEFORE BEGINNING ANY

AUTORAKE

®

MAINTENANCE

BEFORE EACH USE

•

Make sure that all nuts and bolts are in place and properly tightened.

•

Make sure that all other fasteners are in place and are performing their specified function.

•

Make sure that all hydraulic fittings are tightened and that there are no leaks in any fittings or hoses.

•

Make sure that all safety signs are in place, are clean, and are legible.

(SEE THE SAFETY SIGN SECTION ON PAGE 5.)

•

Replace any damaged parts and excessively worn parts. Replace the rake chain when the raking action has been

reduced to an inefficient level.

AFTER EVERY 10 HOURS OF USE

•

Grease 11 fittings: one on each of the six bearings (one on each end of the two idler shafts and one on each end of

the drive shaft),

two on each of the two swing arms where the main housing pivots on the bucket, and

one on the barrel end of the hydraulic cylinder.

AFTER EVERY 30 HOURS OF USE

•

Check the drive chain and the rake chain tension and adjust if necessary. (See AUTO-RAKE SERVICE on page 9)

•

The proper tension on the drive chain results in the longest run of chain having a 3/8” to 1/2” midpoint deflection.

•

The proper tension on the rake chain results in the top run of chain (i.e. from the front idler shaft to the drive shaft)

having a 3/4” to 1” midpoint deflection. (Note: For this chain, the combined up and down midpoint deflection of 1-

1/2” to 2” may be easier to measure.)

•

Check the rake chain travel to make sure that the chain is centered on the idlers. Adjust the front idler if centering is

necessary.

AFTER EVERY 250 HOURS OF USE

•

Check the drive chain, the drive and driven sprockets, the drive shaft, and the idler shafts for excessive wear and

replace if necessary.

IMPORTANT

Using heat to straighten bent rake chain teeth

CAN result in damage to this product and

WILL void all FFC warranties.

•

Check for bent rake chain teeth and cold straighten those teeth.

BEFORE EXTENDED STORAGE (More than 2 month)

•

Oil the drive chain and all 3 rake chains.

8

Содержание AUTORAKE LAF6866

Страница 11: ...PARTS ILLUSTRATION 10...