the output. The signal change signals the start of pressure monitoring. If the pres-

sure remains in the monitoring range [d.SP] around P

Ref

, the pressure is stable.

When the monitoring range is left (e.g. caused by a leakage in the system), the

output switches back.

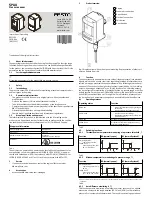

1 Reference value is determined

2 Measured value deviates by

[d.SP] from the reference value

3 Monitoring range

Fig. 2

The parameters [SP.Lo], [SP.Hi], [t.obS] and [d.SP] can be configured by the user.

The greater [t.obS] is set, the more constant the pressure signal must be to estab-

lish the reference value P

Ref

.

Function

NO (normally open)

NC (normally closed)

Switching function:

–

2 switching points (SP.Lo,

SP.Hi) for setting the valid

work range

–

1 switching point (d.SP)

for determination of the

monitoring area

TEACH mode

1)

:

–

2 Teach points (TP1, TP2)

–

TP1 = SP.Lo, TP2 = SP.Hi

SP.Lo P

Ref

SP.Hi

d.SP

1

0

Out

p

1

SP.Lo P

Ref

SP.Hi

d.SP

0

Out

p

1) SP.Lo = smaller pressure value, SP.Hi = larger pressure value, independent of the Teach sequence

Tab. 5

7

Installation

Work on the product should only be conducted by qualified personnel.

7.1

Mechanical and pneumatic

NOTICE!

An unfavourable mounting position can impair the function of the product.

•

Mount the sensor so that no condensation from the compressed air lines can

gather in the device.

•

Install the sensor so that it cannot be heated above the maximum permissible

operating temperature (plan for convection possibilities).

Installation

SPAU-...-T

–

Seal connecting thread.

Tightening torque: max. 10 Nm

(tightening torque M5 female thread: max. 2 Nm)

Tightening torque: max. 7 Nm

SPAU-...-H

SPAU-...-A

Screws: M3

Tightening torque: max. 0.5 Nm

Mounting bracket hole pattern

è

Fig.3

Installation

SPAU-...-W

1.

Wall mounting hole pattern

è

Fig.3

2.

SPAU-...-F

34

±

0,3

61

±

0,3

s

Front panel cut-out in mm

–

Guide sensor from the front into the cut-out

on the front panel.

–

Attach the clamping plate and press until

the fastening slide clips in.

Screws: M3

Tightening torque: max. 0.7 Nm

s

<

2 mm: remove 1 washer

s

<

1 mm: remove 2 washers

SPAU-...-MS...

1.

2.

Tightening torque: max. 1 Nm

Tab. 6

7.1.1

Hole patterns

Fig. 3 Left wall mounting, right mounting bracket

7.2

Electrical

WARNING!

Risk of injury due to electric shock.

•

For the electric power supply, use only PELV circuits that ensure a reliable

electric disconnection from the mains network.

•

Observe IEC 60204-1/EN 60204-1.