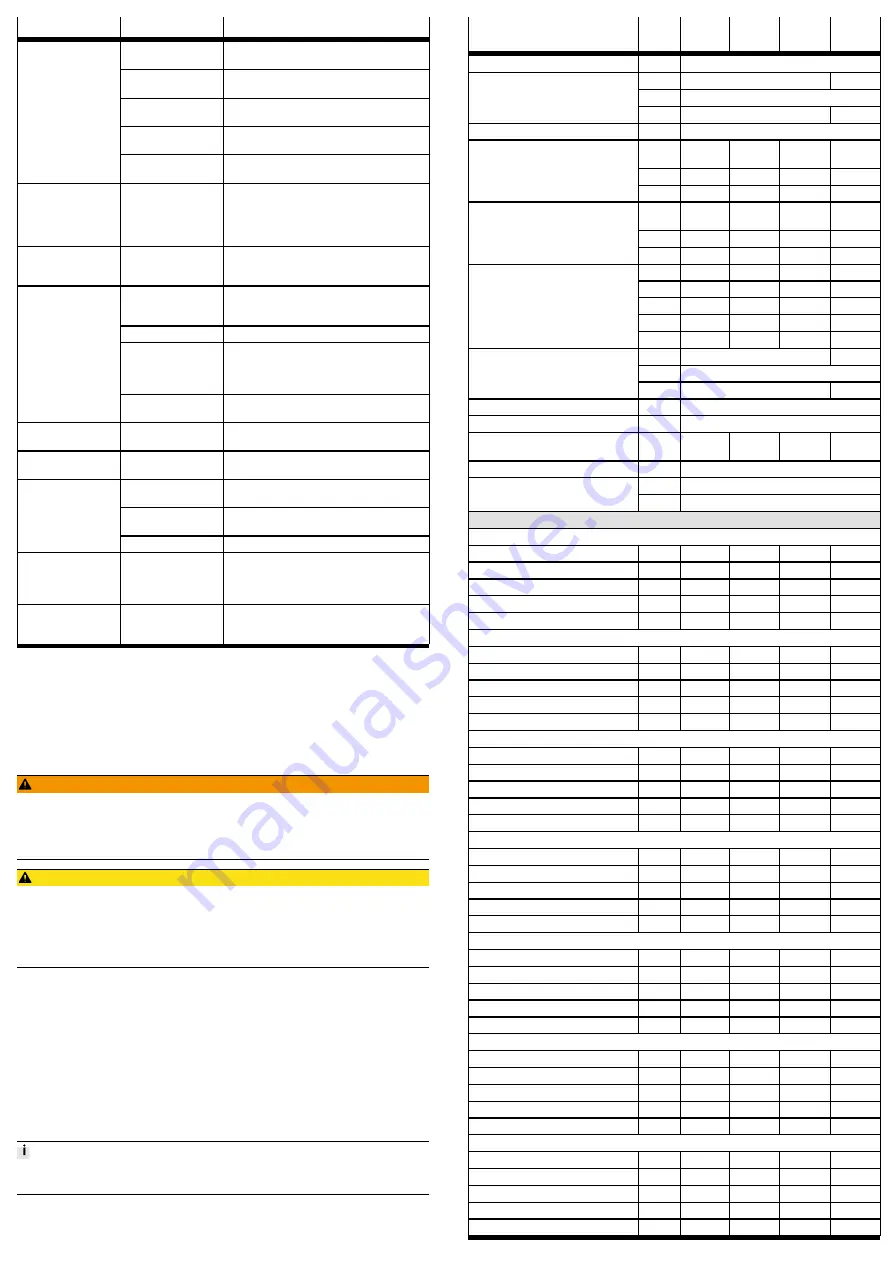

Malfunction

Possible cause

Remedy

Current controller set

tings.

Optimise controller data (e.g. velocity, accelera

tion, ...).

Resonance oscillation

of the axis.

Change the travel velocity.

Wear on bearing or

guide.

–

Contact local Festo Service.

–

Replace axis

è

Toothed belt wear.

–

Contact local Festo Service.

–

Replace axis

è

Loud running noises,

vibrations or rough

running of the axis.

Insufficient lubrication

of guide.

Lubricate the guide

è

Vibrations on the slide.

Operation at the reson

ant frequency of the

axis.

–

Change the travel velocity.

–

Change the acceleration.

–

Increase axis stiffness (e.g. shorter support

distances).

–

Change the payload geometry.

Long oscillations of the

profile.

Resonant frequency of

profile and payload too

low.

–

Increase axis stiffness (e.g. shorter support

distances).

–

Change the payload geometry.

Coupling slips.

Check the mounting of the shafthub connection

è

Instruction manual for the motor mounting

kit, www.festo.com/sp.

Loads too high.

Reduce forces and torques. Consider dynamics.

Screws too long for fix

ing the attachment

component (e.g. pay

load).

Observe the screwin depth

è

Tab. 5 Information on attachment

Slide does not move.

Toothed belt ripped.

–

Contact local Festo Service.

–

Replace axis

è

Overruns the end posi

tion.

Sensor does not

switch.

Check sensor, installation and parameterisation.

Idling torque too high.

Wear in the drive train.

–

Contact local Festo Service.

–

Replace axis

è

Toothed belt preten

sioning too low.

–

Contact local Festo Service.

–

Replace axis

è

Current controller set

tings.

Optimise controller data (e.g. velocity, accelera

tion, ...).

Toothed belt skips.

Loads too high.

Reduce travel speed.

Wave formation on the

cover strip or alumini

um abrasion on the

axis.

Wear on belt reversals.

–

Retension cover strip.

–

Replace belt reversal and cover strip

è

Oil leak between pro

file housing and cover.

Fully suctioned oil

sensor.

ELGATBRF:

–

Replace oil sensor.

–

Contact local Festo Service.

Tab. 10 Overview of fault clearance

11.2

Repair

–

Observe the information for dismantling

è

–

Send axis to Festo repair service.

–

Information about spare parts and accessories

è

12

Disassembly

WARNING!

Unexpected movement of components.

Injury due to impacts or crushing.

•

Before working on the product, switch off the control and secure it to prevent

it from being switched back on accidentally.

CAUTION!

For vertical or slanted mounting position: when power is off, moving parts can

travel or fall uncontrolled into the lower end position.

Injury due to impacts or crushing.

•

Bring moving parts of the product into a safe end position or secure them

against falling.

1. Remove electrical installations with accessories.

2. Remove motor and mounting kit.

3. Remove the mounting attachments.

4. Observe transport information

è

13

Disposal

Dispose of the product and packaging at the end of its useful life through environ

mentally friendly recycling in accordance with applicable regulations.

14

Technical data

14.1

Technical data, mechanical

To size the axis, use the PositionDrives engineering software

è

Size

70

80

120

150

Design

...

Electromechanical axis with toothed belt

G

Plainbearing guide

–

KF

Recirculating ball bearing guide

Guide

RF

Roller bearing guide

–

Mounting position

...

any

G

RF

350

800

1300

–

KF

350

800

1300

2000

Max. feed force Fx

[N]

F1

260

600

1000

–

G

RF

5

15.9

34.1

–

KF

5

15.9

34.1

73.9

Max. driving torque

[Nm]

F1

3.7

11.9

26.2

–

G

0.5

1

3

–

KF

0.6

1

2.8

4

KFF1

0.8

1.5

4.5

–

RF

0.7

1.4

3

–

Max. idling driving torque at

v = 0.2 m/s and with cover

strip

[Nm]

RFF1

1

1.9

5.7

–

G

5

–

KF

5

Max. speed

[m/s]

RF

10

–

Max. acceleration

[m/s

2

]

...

50

Repetition accuracy

[mm]

...

±

0.08

Feed constant

[mm/re

v]

...

90

125

165

232

Ambient temperature

[°C]

...

10 … +60

IP40

Degree of protection

P0

IP00

Max. permissible forces and torques on the slide

ELGATB...G

Fy

[N]

...

80

200

380

–

Fz

[N]

...

400

800

1600

–

Mx

[Nm]

...

5

10

20

–

My

[Nm]

...

30

60

120

–

Mz

[Nm]

...

10

20

40

–

ELGATB...KF, ELGATB...KFF1

Fy

[N]

...

1500

2500

5500

11000

Fz

[N]

...

1850

3050

6890

11000

Mx

[N]

...

16

36

104

167

My

[N]

...

132

228

680

1150

Mz

[N]

...

132

228

680

1150

ELGATB...RF, ELGATB...RFS

Fy

[N]

...

500

800

2000

–

Fz

[N]

...

500

800

2000

–

Mx

[Nm]

...

11

30

100

–

My

[Nm]

...

20

90

320

–

Mz

[Nm]

...

20

90

320

–

ELGATB...RFL

Fy

[N]

...

500

800

2000

–

Fz

[N]

...

500

800

2000

–

Mx

[Nm]

...

11

30

100

–

My

[Nm]

...

40

180

640

–

Mz

[Nm]

...

40

180

640

–

ELGATB...RFXS

Fy

[N]

...

–

800

2000

–

Fz

[N]

...

–

800

2000

–

Mx

[Nm]

...

–

30

100

–

My

[Nm]

...

–

40

150

–

Mz

[Nm]

...

–

40

150

–

ELGATB...RFF1, ELGATB...RFSF1

Fy

[N]

...

400

640

1600

–

Fz

[N]

...

400

640

1600

–

Mx

[Nm]

...

8.8

24

80

–

My

[Nm]

...

16

72

256

–

Mz

[Nm]

...

16

72

256

–

ELGATB...RFF1L

Fy

[N]

...

400

640

1600

–

Fz

[N]

...

400

640

1600

–

Mx

[Nm]

...

8.8

24

80

–

My

[Nm]

...

32

144

512

–

Mz

[Nm]

...

32

144

512

–