Disassembly

Switch off the energy supplies in the following sequence to allow the integrated

valve block to safely vent the drive:

1. First switch off the operating voltage supply.

2. Only after that switch off the compressed air supply.

Only when the drive is vented can the piston rod be shifted manually, for example

to push the piston rod in for safe transport.

Repair

Repairs to the product are only permissible by Festo's repair service.

10

Fault clearance

Malfunction

Possible cause

Remedy

The DFPI closes the

process valve, even

though a different

setpoint is specified.

Operating voltage supply or the analogue

setpoint is outside of the permitted range

(e.g. in the event of a wire break); the DFPI

moves to the safety position

Check operating

voltage supply and

analogue setpoint

Even though the energy

supply is switched off, the

piston rod cannot be

shifted manually.

The drive has not been vented because

the compressed air supply was switched

off first, and then the operating voltage

supply.

First switch off the op

erating voltage supply,

and then the com

pressed air supply.

Current at the analogue

output

3.5 mA

Device errors

Check operating

voltage supply,

operating pressure

and analogue setpoint

Current at the analogue

output = 21.0 mA

The device must be taught

Initialise device

Current at the analogue

output = 21.5 mA

Device is in teach-in status

–

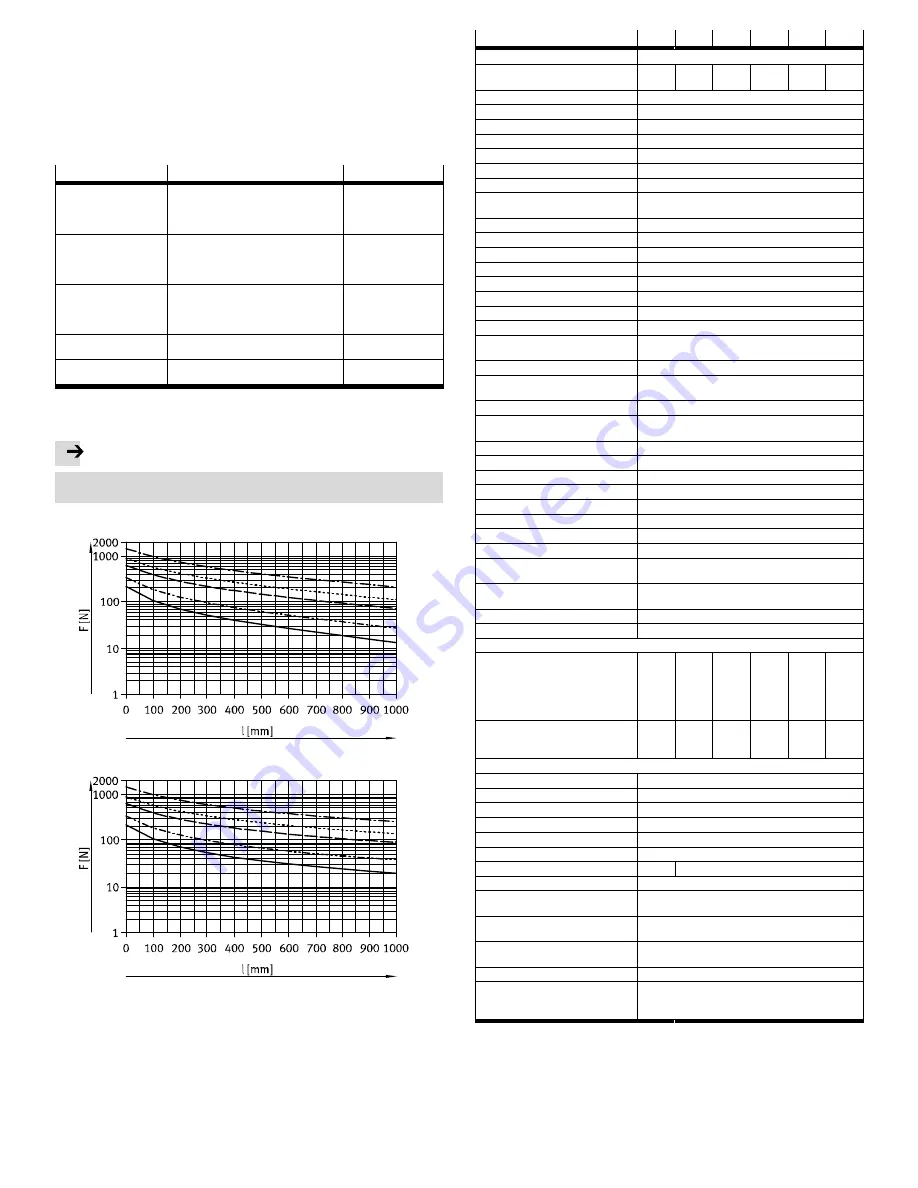

Fig. 10

Max. permissible lateral force for static application

Note

In controlled operation, adjustment of the max. lateral force to the type of con

trol may be required.

Horizontal mounting

Vertical mounting

Fig. 11

11

Technical data

DFPI-…-C1V-NB3P-A

-100

-125

-160

-200

-250

-320

Type of mounting

Mounting interface in accordance with ISO 15552

Width across flats, spanner flat on the

piston rod

22

27

36

36

46

55

Stroke

[mm]

40…990

Min./max. stroke allowance

[mm]

0…4

Design

Piston rod, cylinder barrel

Cushioning

No cushioning

Assembly position

any

Mode of operation

Double-acting

Position sensing

With integrated displacement encoder

Measuring principle of displacement

encoder

Potentiometer

Electrical connection

5-pin; straight plug; screw terminal

Operating voltage range

[V DC]

24 ± 10 %

Nominal operating voltage

[V DC]

24

Max. current consumption

[mA]

220 (at 24 V DC)

Idle current

[mA]

40 (at 24 V DC)

Analogue input

[mA]

4…20

Max. load of the analogue input

[Ω]

Max. 500

Analogue output

[mA]

4…20

Max. load of the analogue

output

[Ω]

Max. 600

Accuracy of analogue output

[% FS]

±1

Analogue output response

time

[ms]

< 100

Initialisation input

[V DC]

22.8…26.4; I = 11 mA at 24 V DC

Protection against polarity reversal

Operating voltage, setpoint value, initialisation connec

tion

Max. cable length

[m]

15

Positioning accuracy

[% FS]

1.0

Repetition accuracy

[% FS]

±1.0

Hysteresis

[% FS]

±1.0

Size of the dead zone

[% FS]

1.0

Operating pressure

[bar]

3…8

Nominal operating pressure

[bar]

6

Operating medium

Compressed air to ISO 8573-1:2010 [7:4:4]

Note on the operating medium

Operation with lubricated medium possible (in which

case lubricated operation will always be required)

Degree of protection - in mounted

status

IP65, IP67, IP69K, NEMA 4

Ambient temperature

[°C]

–5…+50

Relative air humidity

[%]

5…100, condensing

Product weight

Basic weight with 0 mm stroke

– DFPI

-…-

ND2P-C1V-P

[g]

5 280

7 950

14 330

20 410

35 370

57 550

– Additional weight per

10 mm stroke (not moving

mass)

[g]

90

134

200

238

358

582

Moving mass with 0 mm stroke

[g]

1060

1900

3700

4800

9300

16500

– Additional weight of moving

mass per 10 mm stroke

[g]

28

53

89

89

134

227

Note on materials

– Cylinder barrel

Anodised wrought aluminium alloy

– Cap (end cap)

Coated wrought aluminium alloy

– Bottom cap (bearing cap)

Coated die-cast aluminium

– Tie rods

High-alloy stainless steel

– Piston rod

High-alloy stainless steel

– Flange screws/nuts

Coated steel

– Piston rod seals

PUR

NBR

– Static seal

NBR

Note on materials

RoHS-compliant, contains paint-wetting impairment

substances

Vibration resistance in accordance with

DIN/IEC 68, Part 2-6

0.35 mm travel at 10...60 Hz;

5 g acceleration at 60 ... 150 Hz

Continuous shock resistance

in accordance with DIN/IEC 68 Part 2-82

± 15 g at 6 ms duration,

1000 shocks per direction

Certification certificate

RCM

CE certification (see declaration of con

formity

è

www.festo.com)

in accordance with EU EMC Directive

1)

in accordance with EU Explosion Protection Directive

(ATEX)

2)

1)

The device is intended for use in an industrial environment. Outside of industrial environments, e.g. in

commercial and mixed-residential areas, actions to suppress interference may have to be taken.

2)

Certification-specific special documentation must be considered (

è

www.festo.com/sp).

Fig. 12